Quadrupole permanent magnet synchronous motor rotor

A technology for permanent magnet synchronous motors and rotors, applied to synchronous machine parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of low welding strength between the shaft and the iron core and cannot meet the overall performance, and achieve Guarantee the strength, guarantee the effect of operation, and overcome the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

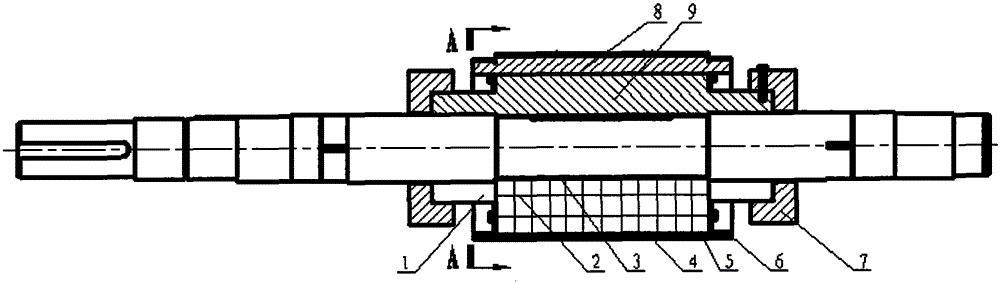

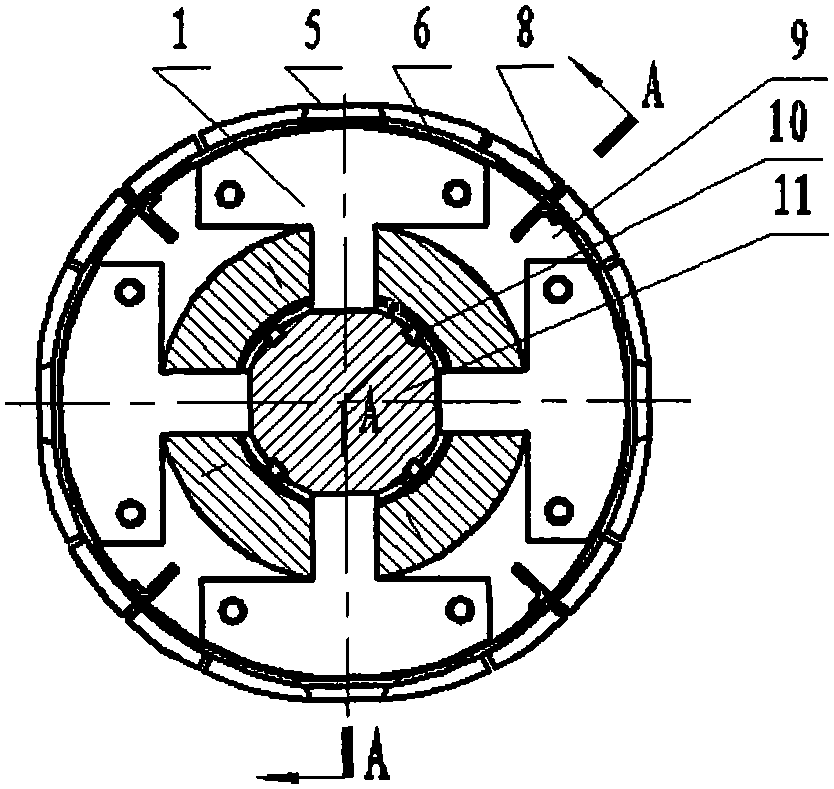

[0023] A kind of quadrupole permanent magnet synchronous motor rotor of the present invention, as figure 1 , 2 As shown, it includes a rotating shaft 11, a key 10, an iron core 9, a magnetic steel 2, a non-magnetic material insulating baffle 1, a collar 6, a copper sheet 8, a slot wedge 5 and a hoop 7;

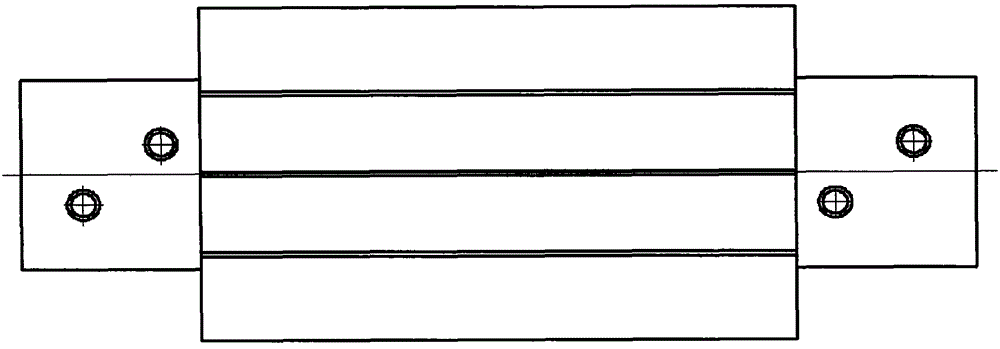

[0024] Such as Figure 5 As shown, an annular groove is processed in the middle section of the rotating shaft 11, and four axially slotted and circumferentially evenly distributed key grooves are processed on the annular groove, and two rows of eight circumferentially evenly distributed misplaced threaded holes are processed on the side walls of the rotating shaft 11 at both ends of the annular groove. ;

[0025] Such as image 3 , 4 As shown, the center of the core 9 is a circular cylinder with an inner diameter and a length matching the annular groove of the rotating shaft 11, which is cut into four fan-shaped sub-pieces with the same structure. The outer wall of each fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com