Mulberry twig stirring positioning device of rocking bar type driving automatic mulberry leaf picking machine

An automatic picking and rocker-type technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

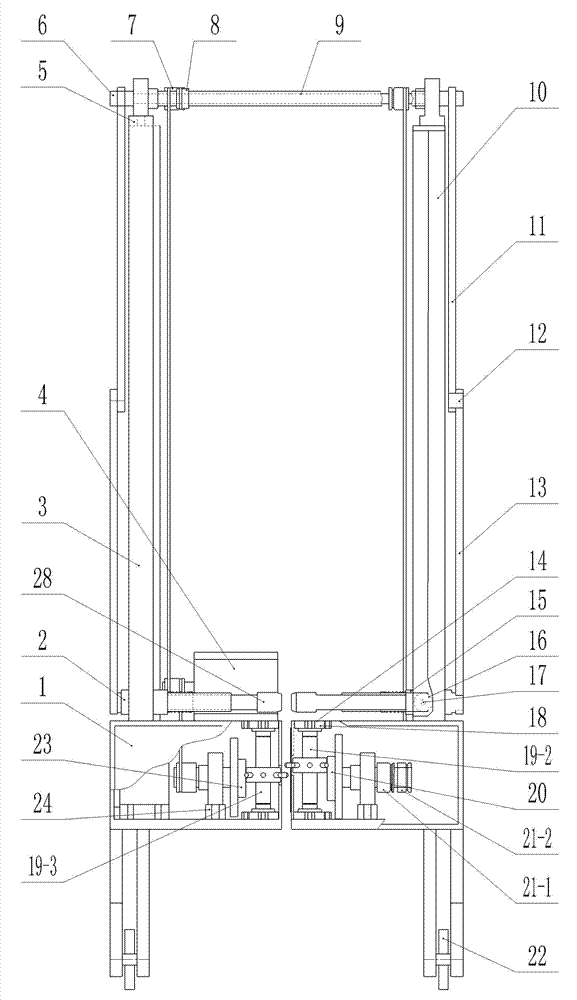

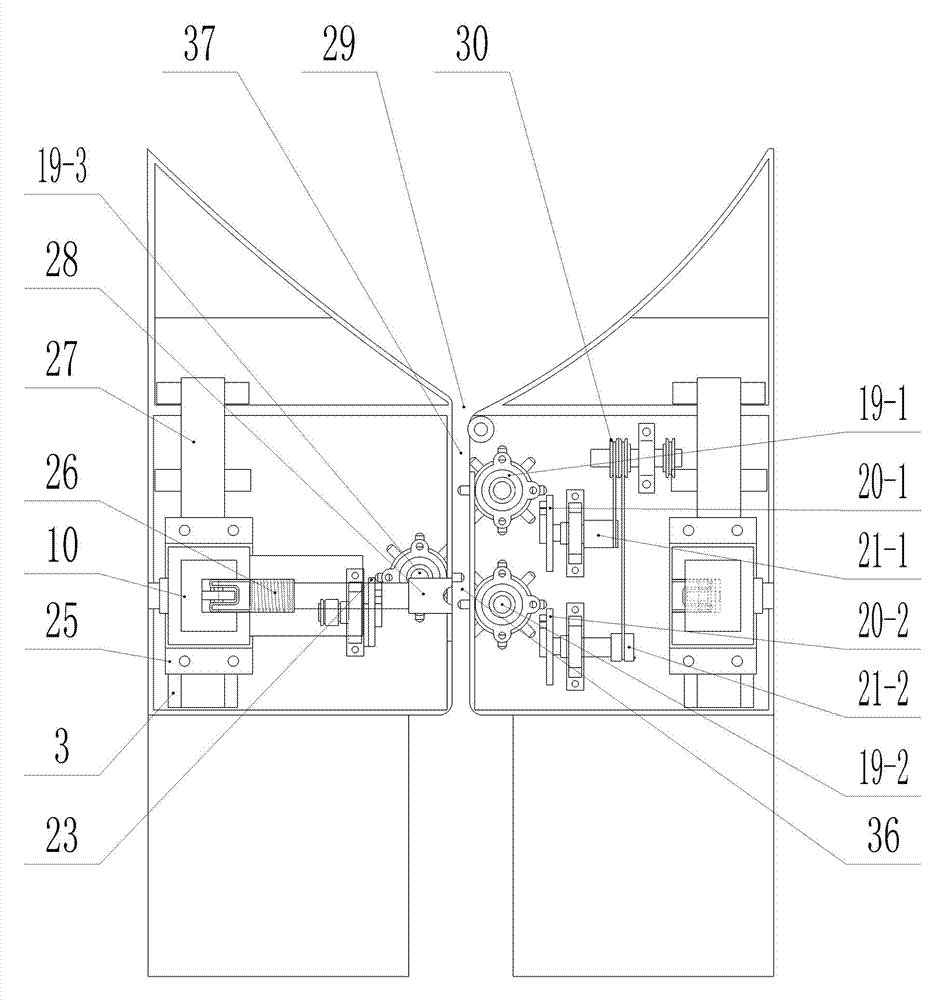

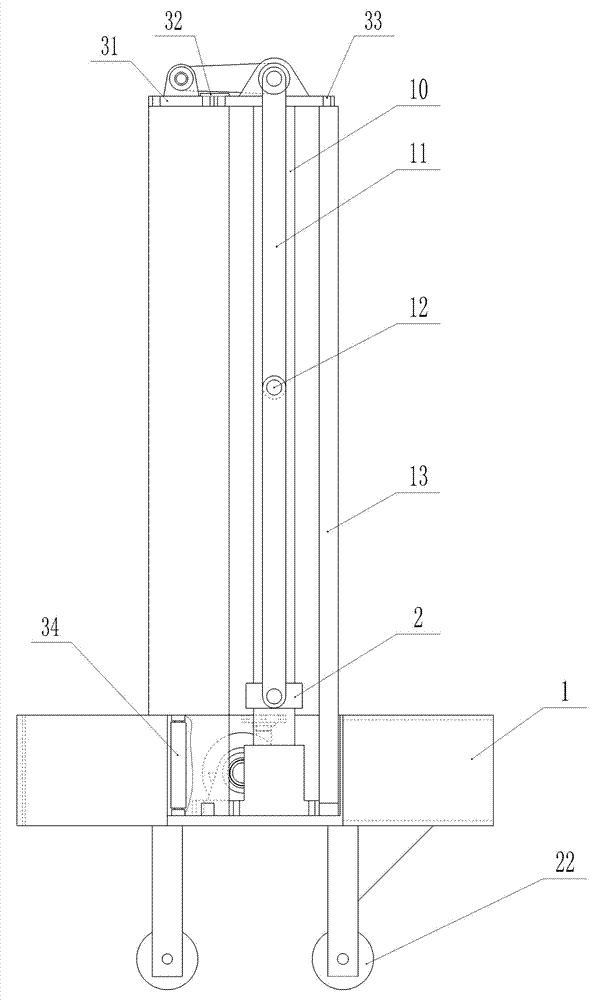

[0024] refer to Figure 1-Figure 9 , a rocker-type driving mulberry leaf automatic picking machine mulberry branch toggle positioning device, comprising a first mulberry branch positioning wheel 19-1, a second mulberry branch positioning wheel 19-2, and a third mulberry branch positioning wheel 19-3 , the first large disk indexing cam 20-1, the second large disk indexing cam 20-2, the small disk indexing cam 23, the first front flywheel 21-1, the first rear flywheel 21-2 and limit Position frame 36, described mulberry branch positioning wheel is provided with a plurality of positioning rods, and the large disc indexing cam and the small disc indexing cam 23 are provided with arc sections for intermittently stirring the positioning rods, wherein the first The positioning rod on the mulberry branch positioning wheel 19-1 abuts against the arc section of the first large disc indexing cam 20-1, and the positioning rod on the first mulberry branch positioning wheel 19-1 is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com