Adaptive deformation-resistant supporting fixture

An anti-deformation and self-adaptive technology, applied in the direction of clamping, supporting, manufacturing tools, etc., can solve the problems of low relative rigidity, uneven clamping force of parts, low processing precision of parts, etc., and achieve enhanced structural rigidity and stable clamping High performance and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

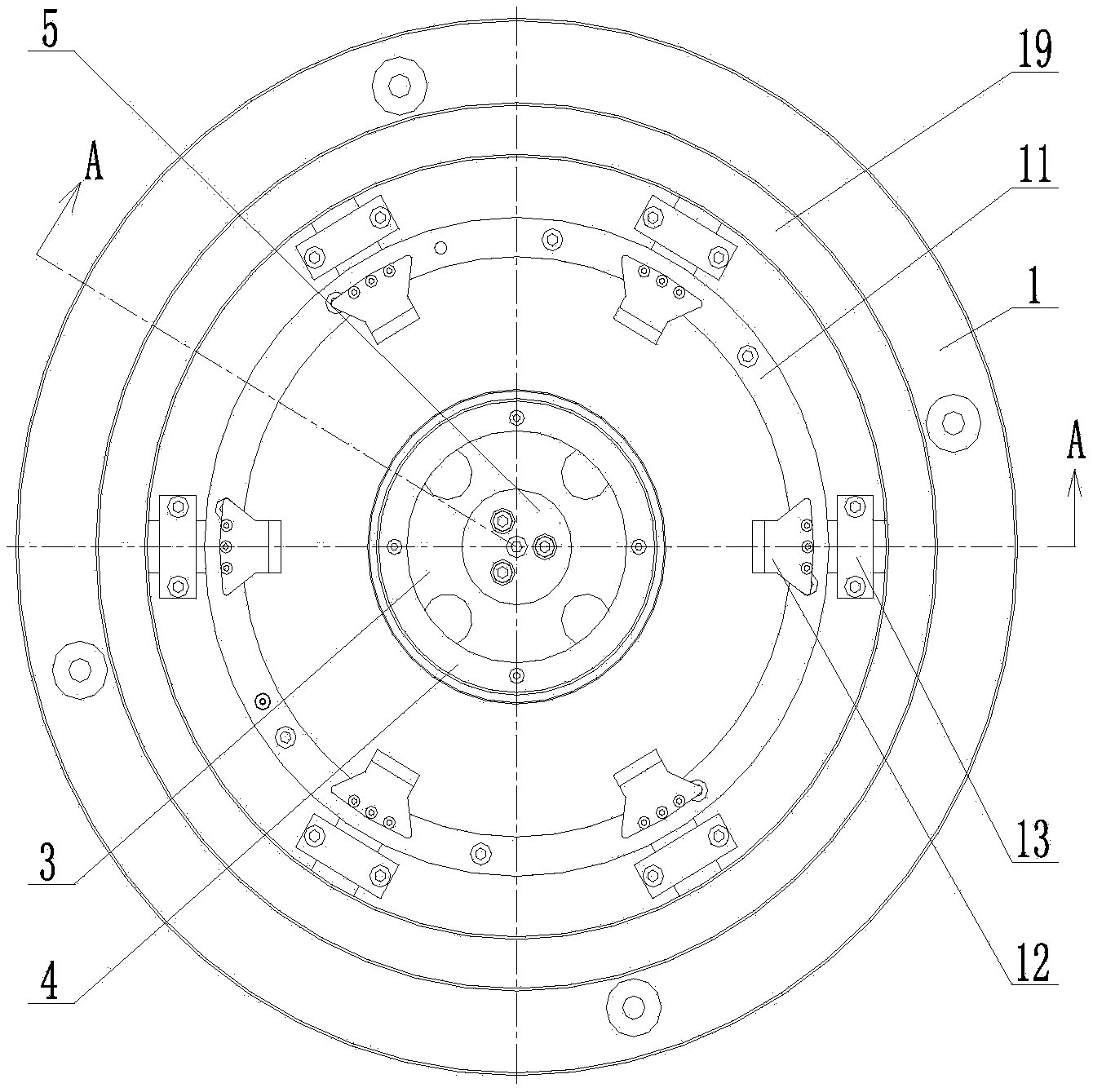

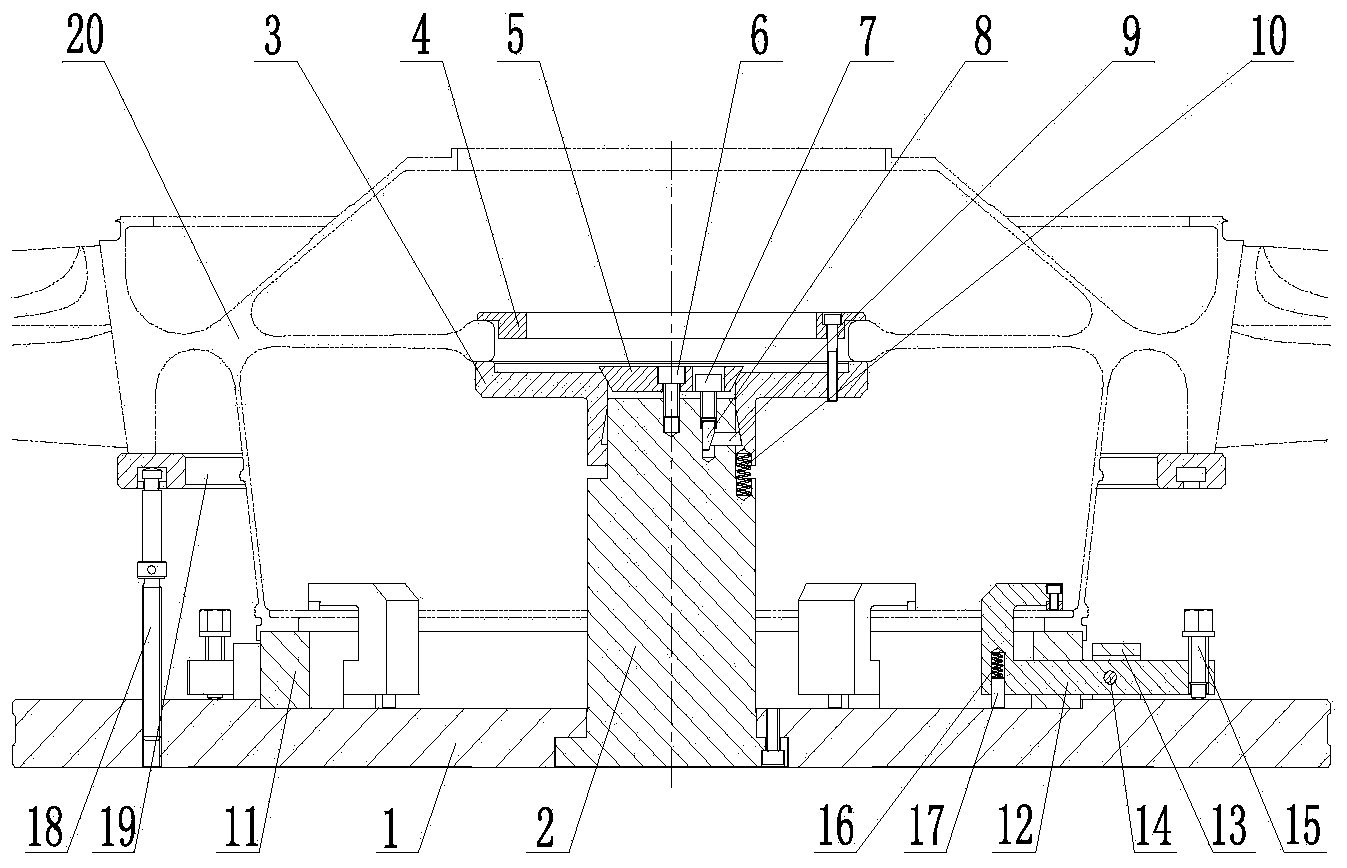

[0020] Such as figure 1 , 2 As shown, an adaptive support anti-deformation fixture includes a base 1, a central support 2, a central support plate 3, a first central pressure plate 4, a second central pressure plate 5, a positioning ring 11 and a circumferential pressure plate 12. The base 1 is set in a disc-shaped structure, the central support 2 is fixed in the center of the base 1, the central support plate 3 is set on the upper end of the central support 2, and the central support plate 3 and the central support 2 in the direction of the set There are four thrust springs 10 evenly arranged therebetween;

[0021] A through hole is provided in the middle of the center support plate 3, and the second center pressure plate 5 contacts and cooperates with the center support plate 3 through the through hole. A first locking bolt 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com