Sterilization oxygen production type vehicle-mounted induced and forced fan

A technology of conveying and drawing fans, applied in vehicle parts, air treatment equipment, transportation and packaging, etc., can solve the problems of inability to perform sterilization, oxygen production, and poor filtering effect of pollutants at the same time, so as to enhance the anti-haze ability, improve the Breathing quality, the effect of improving breathing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

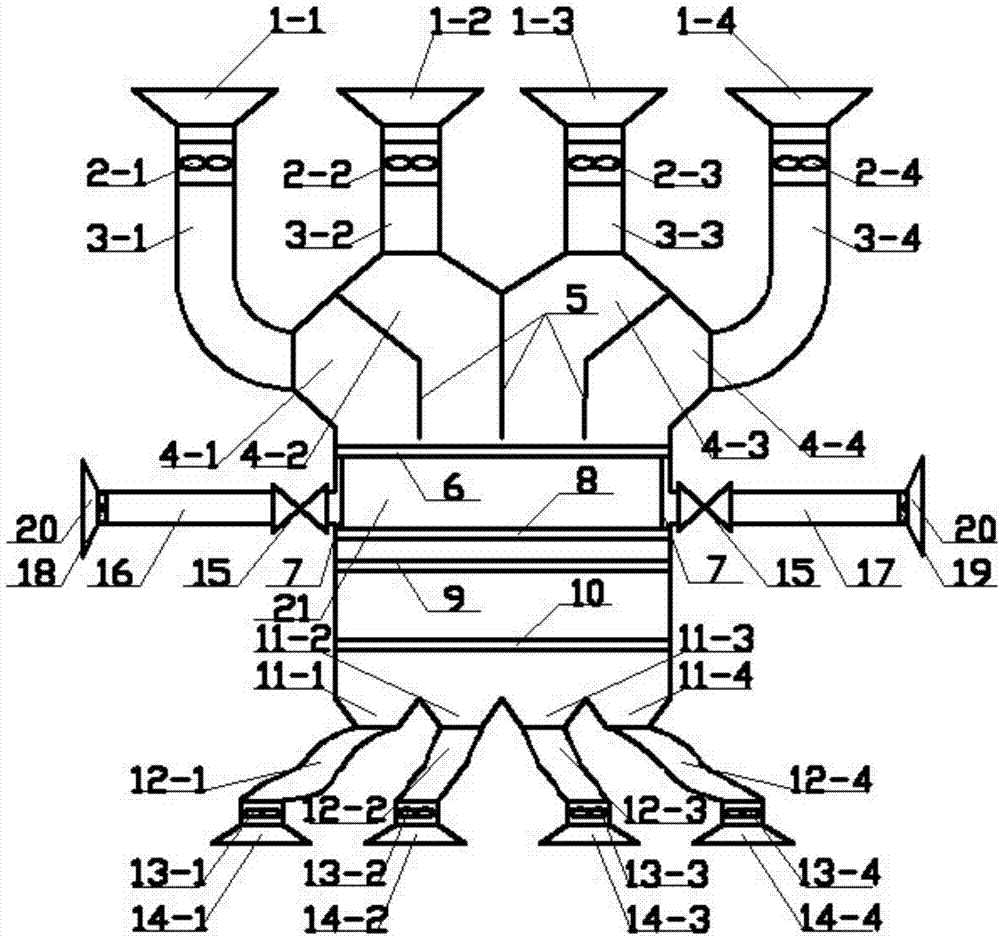

[0011] Specific Embodiment 1: In this embodiment, a vehicle-mounted sterilizing and oxygen-generating fan includes a dust suction shroud 1-1, a dust suction fan 2-1, an air inlet pipe 3-1, an air inlet 4-1, Sponge primary filter 6, ultraviolet lamp 7, manganin copper ozone secondary filter 8, activated carbon tertiary filter 9, sponge final filter 10, new air guide cover 20, induced fan 18, supply fan 19, exhaust Port 11-1, exhaust pipe 12-1, exhaust fan 13-1, and air supply port 14-1; the dust suction guide cover 1-1 is connected with the air inlet 4-1 through the air inlet pipe 3-1 for dust collection The induced fan 2-1 is arranged at the junction of the dust suction shroud 1-1 and the air inlet pipe 3-1, and the sponge primary filter 6 and manganese copper ozone two are arranged in parallel from top to bottom directly below the air inlet 4-1 Stage filter 8, activated carbon three-stage filter 9 and sponge final stage filter 10, ultraviolet lamp 7 is set in the ventilation ...

specific Embodiment approach 2

[0015]Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the vehicle-mounted air blower for sterilization and oxygen generation also includes a dust suction deflector 1-2, a dust suction deflector 1-3, a suction deflector Dust deflector 1-4, dust suction fan 2-2, dust suction fan 2-3, dust suction fan 2-4, air inlet pipe 3-2, air inlet pipe 3-3, air inlet pipe 3 -4, air inlet 4-2, air inlet 4-3 and air inlet 4-4; Dust suction guide cover 1-2, dust suction guide cover 1-3 and dust suction guide cover 1-4 respectively Air port 4-2, air inlet 4-3 and air inlet 4-4 are connected by air inlet pipe 3-2, air inlet pipe 3-3 and air inlet pipe 3-4, dust suction fan 2-2, dust suction fan The fan 2-3 and the suction fan 2-4 are respectively arranged on the dust suction shroud 1-2, the dust suction shroud 1-3 and the dust suction shroud 1-4 and the air inlet duct 3-2, the inlet The connection between the air duct 3-3 and the air inlet duct 3-4...

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the sterilizing and oxygen-generating vehicle-mounted blower fan also includes an air outlet 11-2, an air outlet 11-3, and an air outlet 11-4, exhaust pipe 12-2, exhaust pipe 12-3, exhaust pipe 12-4, exhaust fan 13-2, exhaust fan 13-3, exhaust fan 13-4, air outlet 14- 2. The air supply port 14-3 and the air supply port 14-4 are connected to the air exhaust port 11-2, the air exhaust port 11-3 and the air exhaust port 11-4 directly below the sponge final filter 10, and the air exhaust port 11- 2. The other ends of the exhaust outlet 11-3 and the exhaust outlet 11-4 are respectively connected with the exhaust pipe 12-2, the exhaust pipe 12-3 and the exhaust pipe 12-4, and the exhaust pipe 12-2, the exhaust pipe Pipe 12-3 and exhaust pipe 12-4 other end link to each other with air supply port 14-2, air supply port 14-3 and air supply port 14-4 respectively, in exhaust pipe 12-2, exhaust pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com