A motorcycle sprocket

A large sprocket and motorcycle technology, which is applied to vehicle parts, vehicle gearboxes, chain/belt transmissions, etc., can solve the problems of increasing processing content, large consumption of injection molding materials, and inability to strengthen strength, so as to reduce processing costs , Reduce the consumption of injection molding materials, and the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

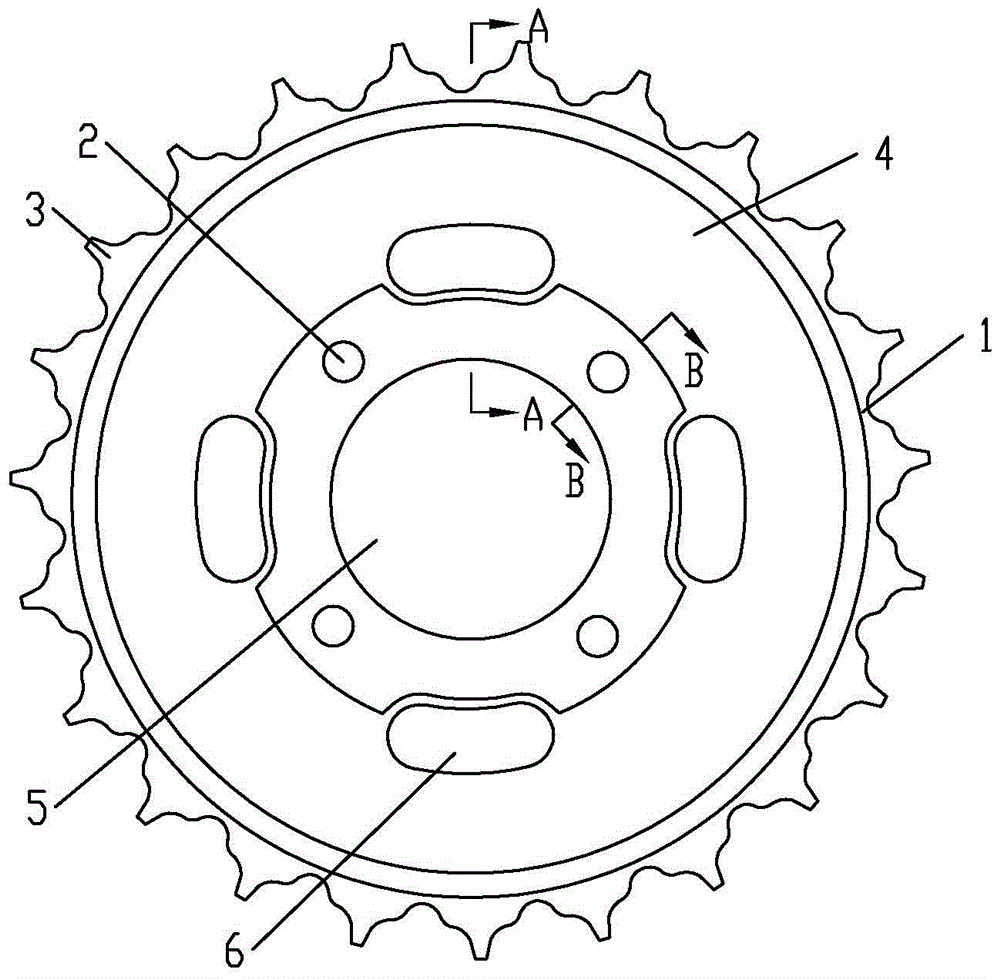

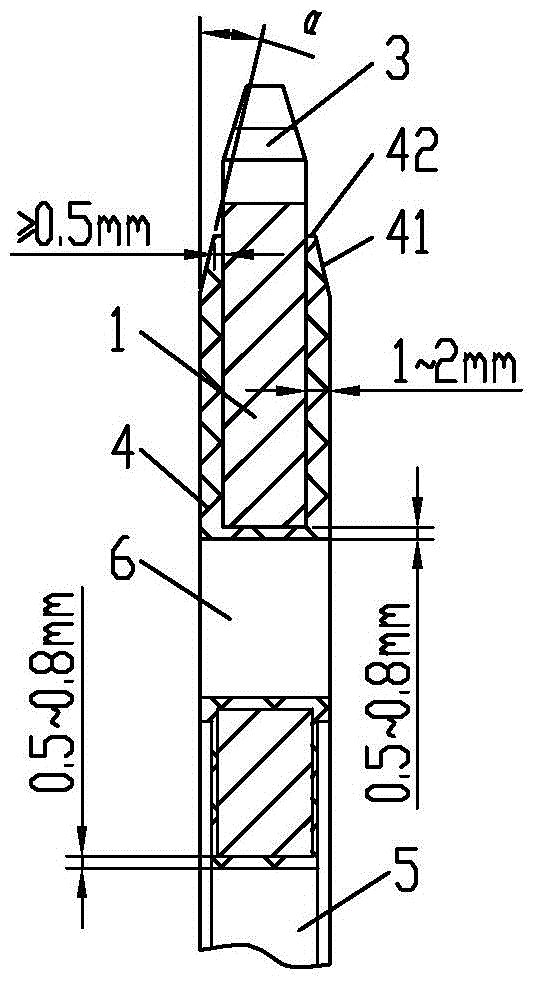

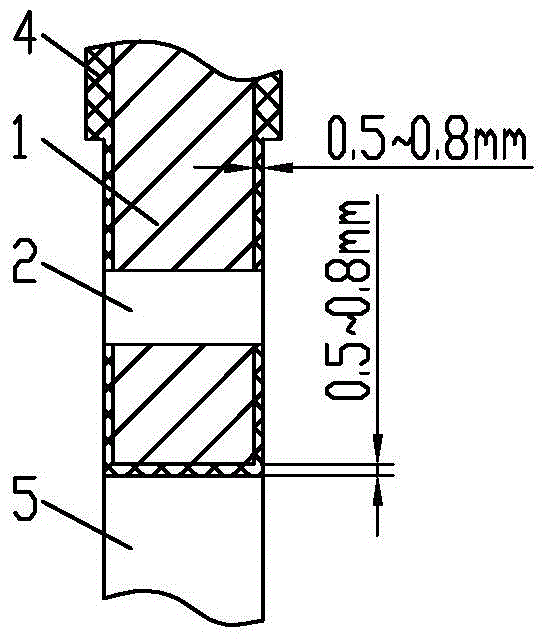

[0016] see figure 1 , a motorcycle large sprocket, comprising a sprocket body 1, the sprocket body 1 is provided with a one-way device positioning hole base hole, a one-way device screw connection hole 2, a weight-reducing hole base hole, and the outside of the sprocket body 1 The sprocket 3 is arranged on the circumference, and the sprocket body 1 is provided with a protective layer 4. The protective layer 4 has a covering layer part of the inner wall of the one-way device positioning hole base hole and the inner wall of the weight-reducing hole base hole, and is respectively in the corresponding position. Form the one-way device positioning hole 5 and the weight-reducing hole 6, and the protective layer 4 forms a hollow at the position of the one-way device screw connection hole 2 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com