Organic magnesium-enriched alloy coating material and preparation method thereof

A coating and organic technology, applied in the field of magnesium-rich alloy coatings, can solve the problems of short protection time and easy failure, and achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

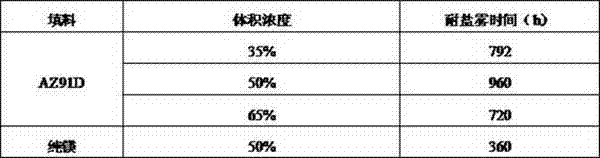

[0015] The filler PVC values of the organic coatings are respectively 35%, 50%, and 65%. In addition, under the condition of 50% PVC, take pure magnesium powder of equal mass as the filler, and do a comparative experiment. Table 1 is the ingredient list of each component of the organic coating under different pigment volume concentration PVC, and the ratio of each component is shown in Table 1 below.

[0016] Table 1 The ingredient list of different pigment volume concentrations.

[0017]

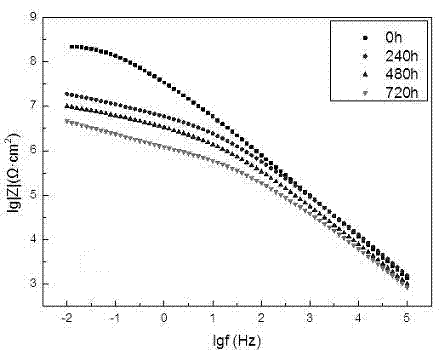

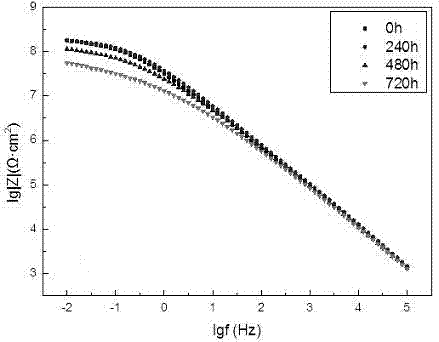

[0018] Table 2 shows the salt spray resistance time of organic coatings under different volume concentration conditions. It can be seen from Table 2 that after different time salt spray tests, the salt spray resistance time of PVC50% is the longest, reaching 960h. The PVC35% and PVC65% coatings are not as good as PVC50% coatings due to the addition of less or more AZ91D.

[0019] Table 2 Salt spray resistance time of coatings with different volume concentrations.

[0020]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com