Cloth skew rolling mill

A cross-rolling machine and cloth technology, applied in textiles and papermaking, liquid/gas/steam textile material treatment, removal of liquid/gas/steam, etc., can solve the problems of poor dyeing effect and large water consumption, and improve the effect, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] This specific embodiment is only an explanation of the present invention, but not a limitation of the present invention. After reading the description of the present invention, any changes made by those skilled in the art will be protected by the patent law as long as they are within the scope of the claims.

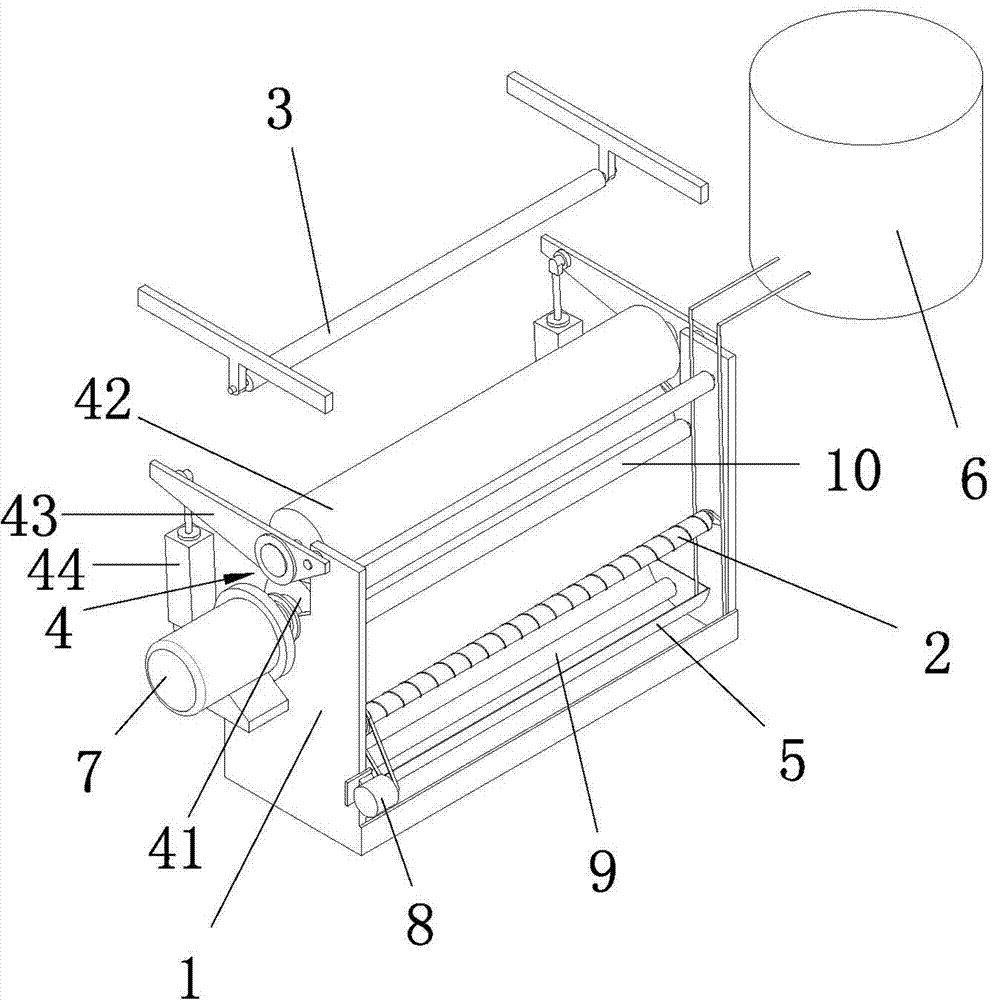

[0020] Such as figure 1 Shown, a kind of cloth cross-rolling mill comprises frame 1, feeding roller 2, tension roller 3 and roll group 4, and described brush roller group comprises a driving roller 41 and a driven roller 42, and described driving roller 41 It is tangent to the driven roll 42, and the plane formed by the axis of the driving roll 41 and the axis of the driven roll 42 is inclined to the horizontal plane, and also includes a water bath 5 arranged at the front end of the roll group 4, the water bath 5 is provided with a dip roll 9; also inclu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap