Outer curtain wall hollowed aluminum board rod net structure and construction method thereof

A hollowed-out aluminum plate and exterior curtain wall technology, which is applied to walls, building components, building structures, etc., can solve problems such as lack of aesthetics and three-dimensional effects, complex installation structure of hollowed-out aluminum plates, difficulty in adjusting the flatness of hollowed-out aluminum plates, etc. The method is simple and practical, the construction is simple and fast, and the effect of being convenient for workers to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

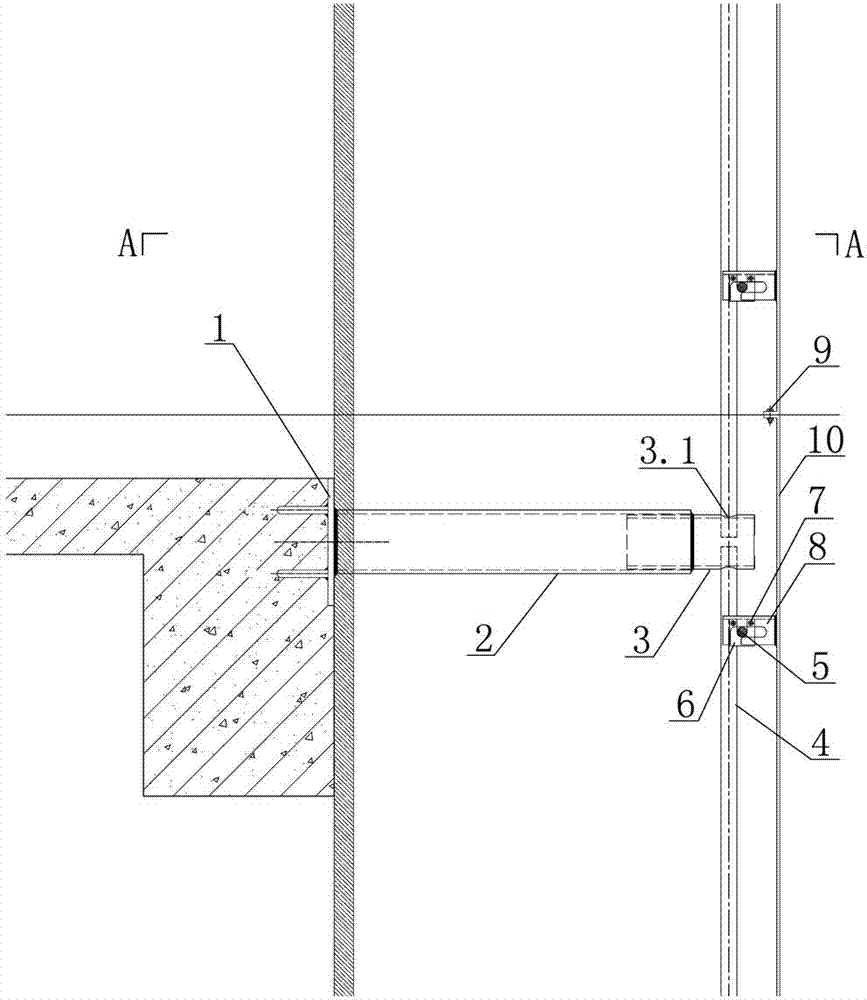

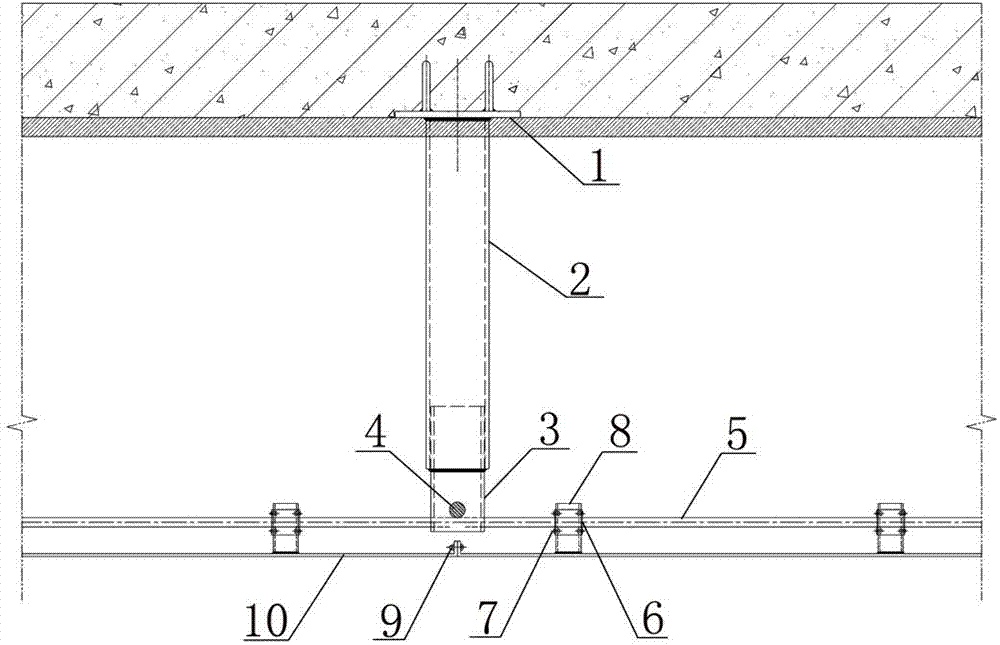

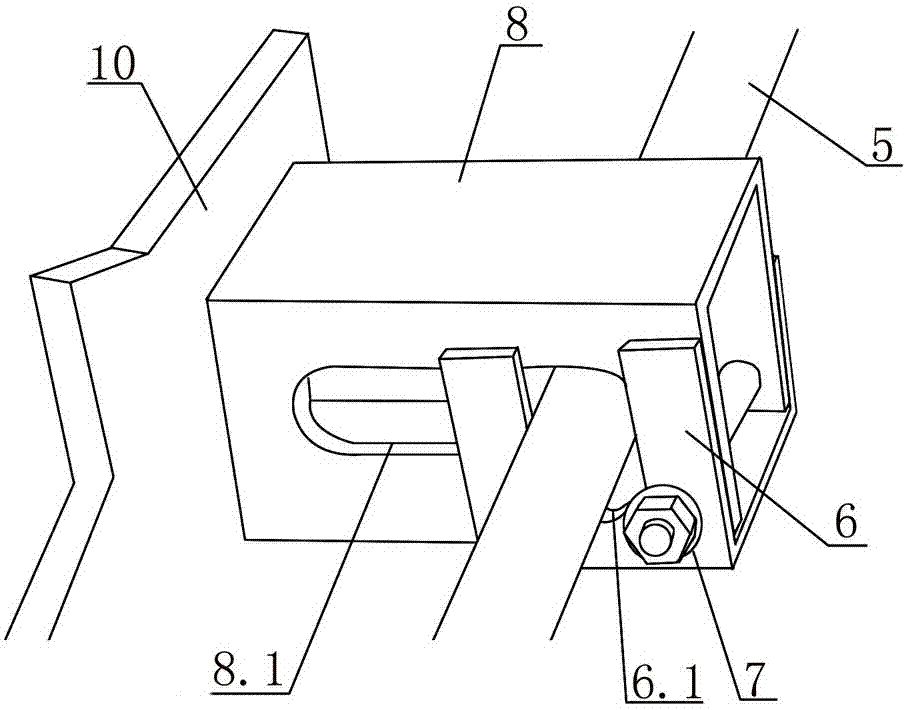

[0037] Examples see figure 1 , figure 2 As shown, this kind of hollowed-out aluminum plate dry-hanging pole net structure of the outer curtain wall includes embedded plate 1 fixed on the concrete slab, steel pipe column 2, sleeve pipe 3, vertical pole 4, horizontal pole 5, positioning piece 6, and blind rivets 7. Mount lugs 8, bolts 9 and hollow aluminum plates 10.

[0038] The steel pipe columns 2 are distributed in a mesh shape perpendicular to the wall, one end of the steel pipe column 2 is welded and fixed to the embedded plate 1, and the other end is inserted into the casing 3, and the casing 3 is fixed to the steel pipe column 2 after adjusting the overall flatness. The part where the pipe 3 extends out of the steel pipe column 2 has a reserved opening 3.1 up and down, and the vertical rod 4 is vertically inserted into the reserved opening of the sleeve pipe 3 and fixed.

[0039] The back of the hollow aluminum plate 10 is welded with a hooking lug 8, and the hooking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com