High-frequency module and method for inspecting high-frequency module

A high-frequency module and high-frequency circuit technology, used in RF circuit testing, instruments, semiconductor/solid-state device testing/measurement, etc., can solve problems such as soaring manufacturing costs and high-frequency module characteristics that do not meet specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

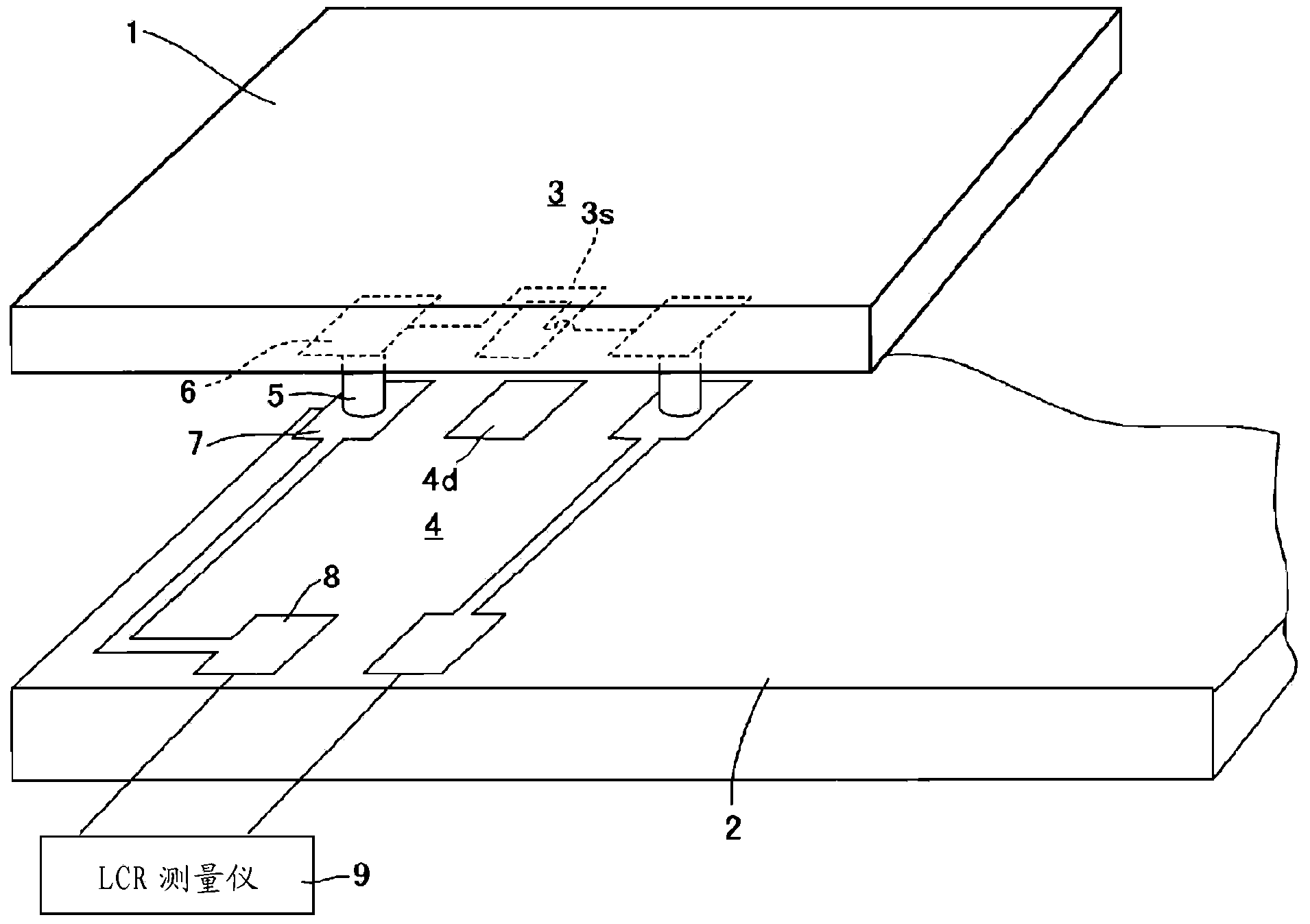

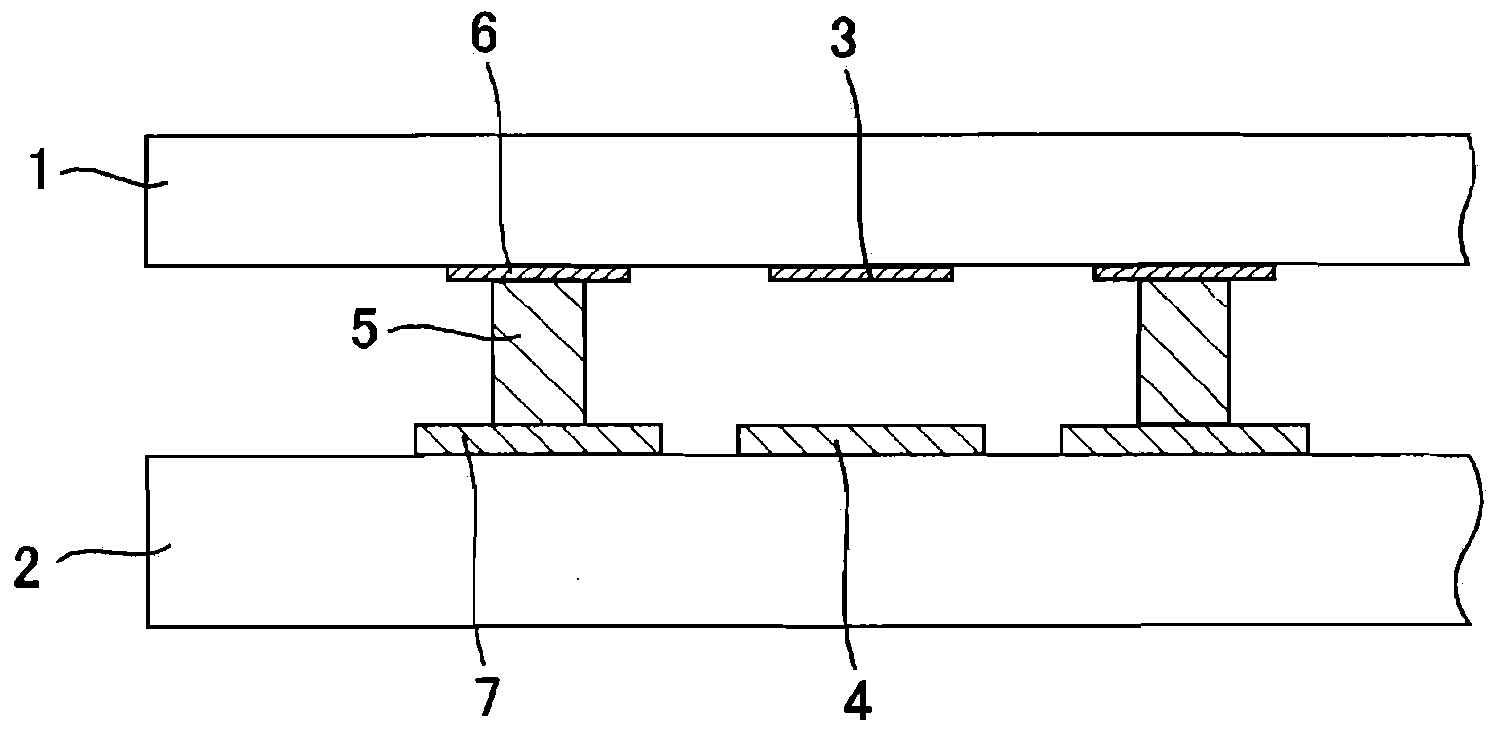

[0067] figure 1 It is an explanatory diagram (perspective view) showing the structure of the high-frequency module according to Embodiment 1 of the present invention, figure 2 is a cross-sectional view. In this embodiment, an example in which a spiral inductor is used as a circuit element for measurement will be described.

[0068]The high-frequency module includes a high-frequency circuit chip 1, a wiring substrate 2 as a module substrate on which the high-frequency circuit chip 1 is assembled, a first circuit 3 formed on the high-frequency circuit chip 1, a second circuit 4 formed on the wiring substrate 2, Bumps 5 connecting electrodes of the high-frequency circuit chip 1 and the wiring board 2 , input / output terminals (electrodes) 6 on the high-frequency circuit chip 1 , and connection pads (electrodes) 7 of the wiring board 2 .

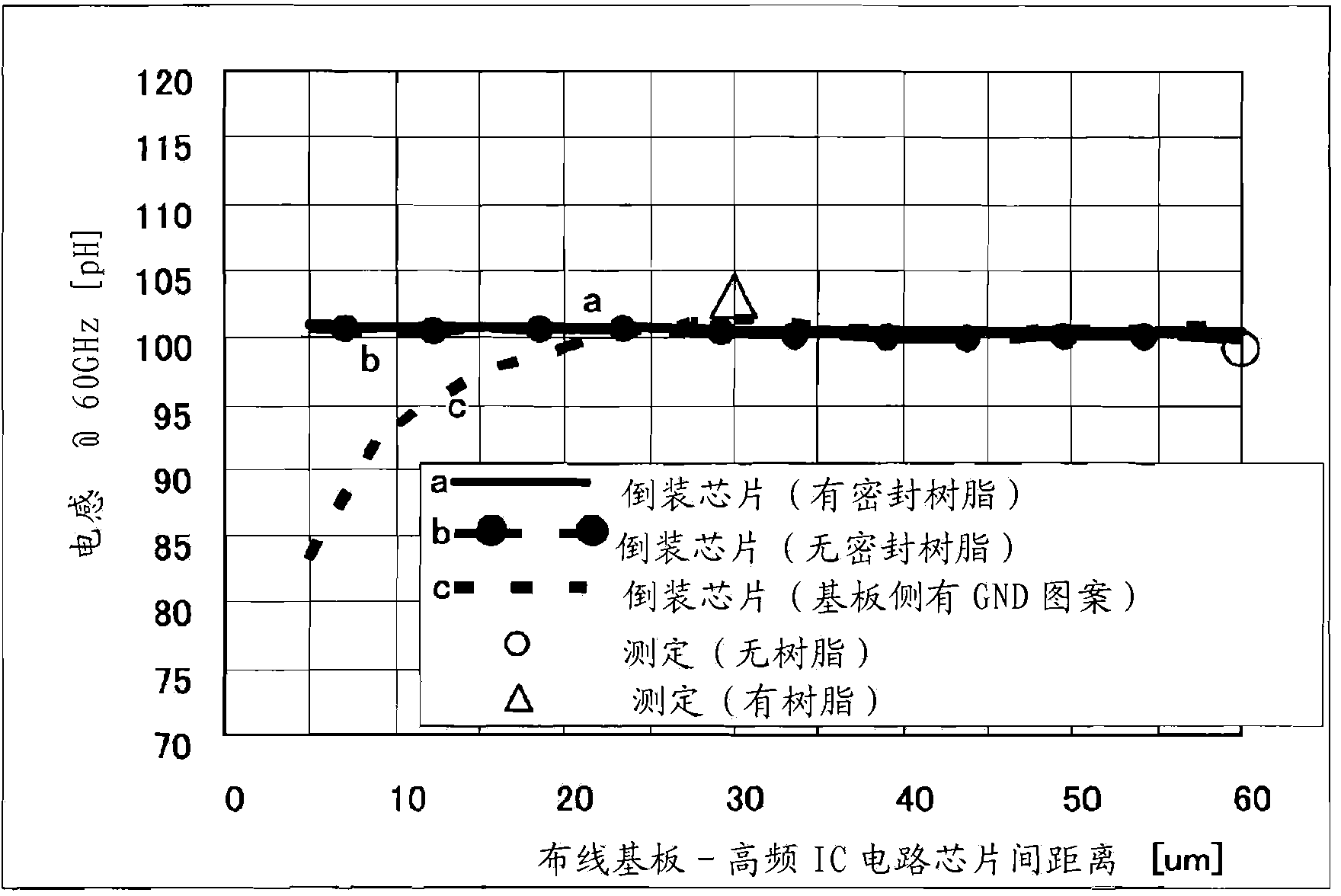

[0069] For example, the first circuit 3 is configured using a spiral inductor 3s, and the second circuit 4 is configured using a detection c...

Embodiment approach 2

[0088] Next, Embodiment 2 of the present invention will be described.

[0089] In the high-frequency module of Embodiment 1, such as Figure 4 As shown in the middle perspective view, the spiral inductor 3s is formed on the high-frequency circuit chip 1, and the detection conductor 4d is formed on the wiring board 2 as the second circuit 4. However, in the high-frequency module according to Embodiment 2, the detection conductor 3d is disposed on the high-frequency circuit chip 1 , and the spiral inductor 4s is disposed on the wiring board 2 .

[0090] Others are the same as those in Embodiment 1, so explanations are omitted here.

[0091] In this embodiment, as in the high-frequency module of Embodiment 1, the inductance caused by the change in the distance between the spiral inductor 3s and the detection conductor 4d is detected by measuring the change in inductance between the connection pads 7 The change of the distance between the input-output terminal 6 and the connecti...

Embodiment approach 3

[0096] Next, Embodiment 3 of the present invention will be described. In addition, in Embodiments 1 and 2, the conductor for detection is formed on the high-frequency circuit chip 1 or the wiring board 2, but as Figure 5 As shown, a detachable outer conductor 4o may also be used.

[0097] On the wiring board 2, the outer conductor mounting part 2o is formed in advance, and the outer conductor 4o is arranged on the outer conductor mounting part 2o, and the distance between the high-frequency circuit chip 1 and the wiring board is measured in the same way as in Embodiments 1 and 2, and bumps are detected. high. The other parts are the same as those of the high-frequency module according to Embodiment 1, so explanations are omitted here.

[0098] That is, the high-frequency module according to Embodiment 1 includes: a high-frequency circuit chip 1 having input and output terminals 6; The wiring substrate 2.

[0099] Furthermore, the first circuit 3 serving as a wiring portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com