Baling device

A technology of a baling device and a material channel, which is applied in the direction of balers, cutters, agricultural machinery and implements, etc., can solve the problems of straw being susceptible to external vibration, wind direction, inability to effectively protect functional components, and low straw pushing efficiency, etc. Achieve the effect of strength and firmness guarantee, stable force, and improved transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below according to the drawings and embodiments.

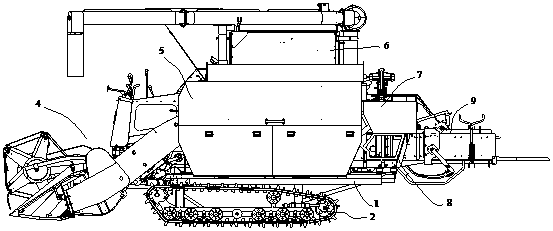

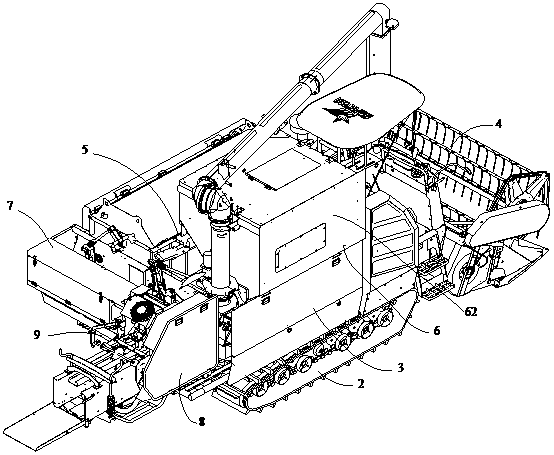

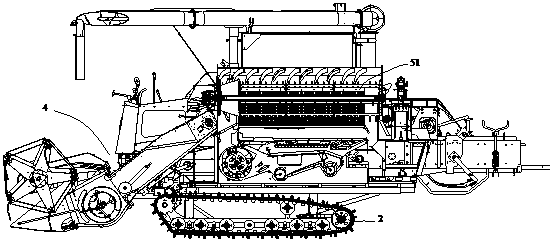

[0059] refer to Figure 1-Figure 19 , a harvesting and bundling integrated machine, which includes a bottom frame 1, a traveling mechanism 2, a power transmission device 3, a harvesting device, and a bundling device. Wherein the harvesting device comprises a header mechanism 4, a threshing mechanism 5, and a grain harvesting mechanism 6. And the bundling device comprises feeding mechanism 7, material pushing mechanism 8, bundling mechanism 9.

[0060] Bottom frame 1 and running gear 2 are prior art, and running gear is the structure of crawler self-propelled type, and its main function part is driving wheel, other functional wheels such as guide wheel, tensioner wheel and drive track. The power transmission device 3 also belongs to the prior art, and what it adopts is a diesel engine. The power of the diesel engine that usually reaches the power matching can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com