Composite microsphere with carbon sphere nucleus and CuO shell and preparation method and application thereof

A technology of composite microspheres and carbon spheres, applied in the field of composite materials, can solve the problems of limited types of organic substances, unfavorable industrial application, unfavorable industrialization promotion, etc., and achieves good visible light absorption characteristics, good degradation effect, and cheap instruments and equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

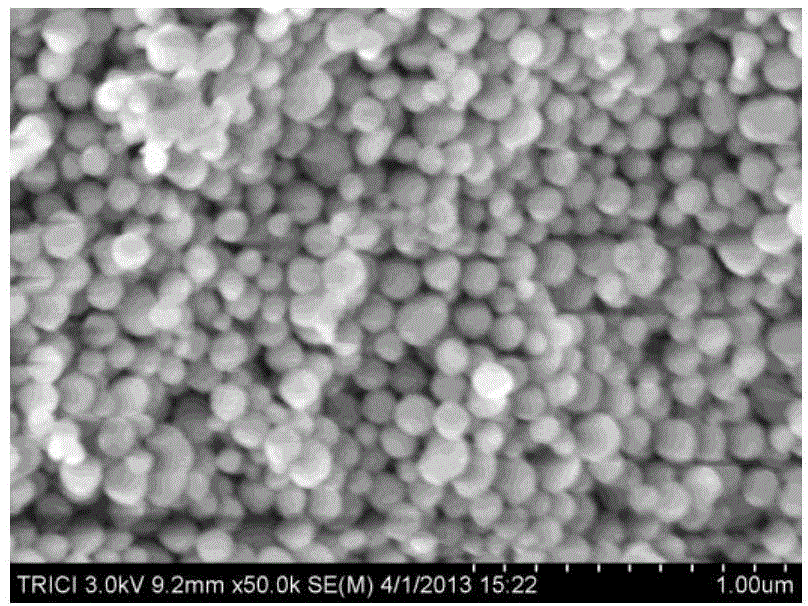

[0030] Dissolve 120mg of potato starch in 120mL of distilled water, dissolve at 100°C for 2h with stirring, and cool to room temperature naturally, then pour the obtained starch solution into an autoclave, perform hydrothermal synthesis at 180°C for 12h, and cool to room temperature naturally, The obtained carbon spheres have a diameter of 200nm, add 0.1793g of copper nitrate, stir evenly at room temperature, further conduct a hydrothermal reaction at 180°C for 10h, cool to room temperature naturally, centrifuge, wash, and dry at 80°C for 10h to obtain carbon spheres with a diameter of 300nm. Carbon sphere CuO core-shell composite microsphere, the shell thickness is about 50nm.

[0031] Weigh 10 mg of carbon sphere CuO core-shell composite microspheres, add 10 mL of methyl orange solution with a concentration of 10 mg / L, stir in a dark box for 30 min to reach adsorption equilibrium, and then irradiate under simulated sunlight for 6 h, pass UV Visible spectrophotometer measured...

Embodiment 2

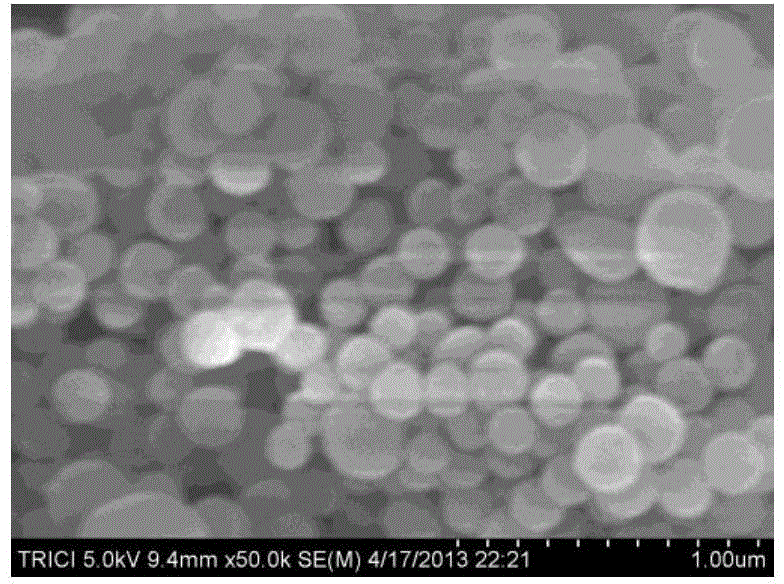

[0033] Dissolve 1200mg of potato starch in 120mL of distilled water, dissolve at 100°C for 5h, cool naturally to room temperature, then pour the obtained starch solution into an autoclave, carry out hydrothermal synthesis at 170°C for 16h, and naturally cool to room temperature, the obtained carbon The diameter of the ball is 280nm, add 1.3424g of copper nitrate, stir evenly at room temperature, further react in hydrothermal reaction at 180°C for 24h, naturally cool to room temperature, centrifuge, wash, and dry at 100°C for 8h to obtain carbon spheres with a diameter of 330nm CuO core-shell composite microspheres, the shell thickness is about 25nm.

[0034] Weigh 10 mg of carbon sphere CuO core-shell composite microspheres, add 10 mL of methyl orange solution with a concentration of 10 mg / L, stir in a dark box for 30 min to reach adsorption equilibrium, and then irradiate under simulated sunlight for 6 h, pass UV Visible spectrophotometer measured the degradation rate of meth...

Embodiment 3

[0036] Dissolve 1200mg konjac starch in 150mL distilled water, dissolve at room temperature for 24h, then pour the obtained starch solution into an autoclave, carry out hydrothermal synthesis at 120°C for 48h, and cool naturally to room temperature, the diameter of the obtained carbon spheres is 880nm , add 7.5120g of copper nitrate, stir evenly at room temperature, further hydrothermally react at 200°C for 24h, naturally cool to room temperature, centrifuge, wash, and dry at 60°C for 24h to obtain a carbon sphere CuO core-shell type with a diameter of 1000nm Composite microspheres, the shell thickness is about 60nm.

[0037] Weigh 10 mg of carbon sphere CuO core-shell composite microspheres, add 10 mL of methylene blue solution with a concentration of 10 mg / L, stir in a dark box for 30 min to reach adsorption equilibrium, then irradiate under simulated sunlight for 10 h, and pass through the ultraviolet Visible spectrophotometer measured the degradation rate of methylene blue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com