Dechlorination method of chlorine rhodochrosite

A technology of rhodochrosite and rhodochrosite, which is applied in the field of chlorine removal of rhodochrosite containing chlorine, can solve the problems of inconvenient storage and transportation of ammonia water, endangering environmental safety, etc., and achieve the effect of convenient source of raw materials, low price and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

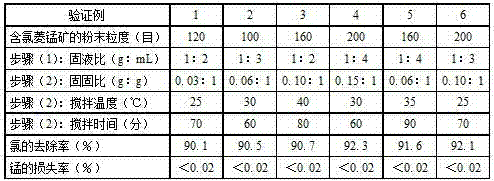

[0012] The invention discloses a method for removing chlorine from chlorine-containing rhodochrosite. The chlorine-containing rhodochrosite in the method has been pulverized into powder before chlorine removal. In the present invention, the powder particle size of described chlorine-containing rhodochrosite is not more than 0.15mm (about 100 meshes of Taylor standard sieve); the steps of the method are as follows:

[0013] (1) At room temperature, add lime slurry to the reactor containing rhodochrosite powder, and stir evenly to obtain a mixed slurry; wherein, rhodochrosite powder: lime slurry = 1g: 2mL ~ 4mL; The ratio of lime slurry is calcium oxide (CaO): water (H 2 O)=40g:1L;

[0014] (2) Add sodium carbonate (Na 2 CO 3 ), and fully stirred under the condition of 25-40°C; wherein, the mass ratio of sodium carbonate to chlorine-containing rhodochrosite powder is 0.03-0.15:1, and the stirring time is not less than 60 minutes;

[0015] The chlorine-containing rhodochrosit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com