Anti-mite oily PU (Polyurethane) transparent finishing coat and preparation method thereof

A transparent topcoat and anti-mite technology, which is applied in the field of coatings, can solve the problems of inconvenient cleaning, high mite recurrence rate, and low mite removal effect, achieving good mite killing effect, low environmental pollution, and avoiding harm to human health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

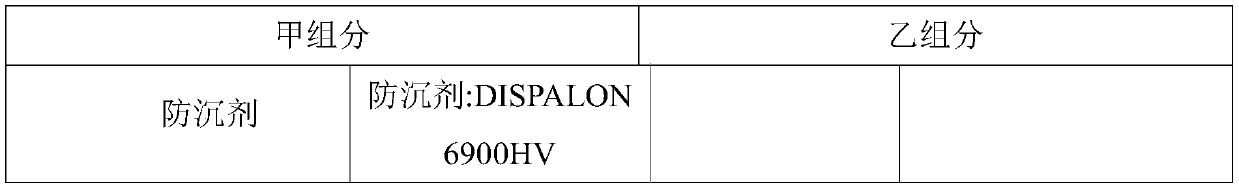

[0047] A kind of anti-mite oily PU transparent topcoat of the present embodiment, comprises A component and B component, and the weight ratio of described A component and described B component is 2:1.5; Described A component is made up of following Component composition in weight percentage: high solid polyol resin 75%, lipid solvent 10%, dispersant 1%, inorganic anti-mite agent 8.15%, defoamer 0.7%, leveling agent 0.15%, anti-settling agent 5% %; The solid content of the first component is 60%.

[0048] The inorganic anti-mite agent is composed of borate, alkaline earth metal and silicate, and the particle size of the inorganic anti-mite agent is 5 μm;

[0049] The B component is composed of the following components in weight percentage: 35% of TDI trimer, 40% of TDI adduct, 25% of butyl acetate, and the solid content of the B component is 42%.

[0050] Wherein, the inorganic anti-mite agent adopts the inorganic anti-mite agent produced by SEGUROCERA.

[0051] The preparati...

Embodiment 2

[0063] A kind of anti-mite oily PU transparent topcoat of the present embodiment, comprises A component and B component, and the weight ratio of described A component and described B component is 2:0.5; Described A component consists of the following Component composition in weight percent: high solid polyol resin 80%, lipid solvent 5%, dispersant 0.5%, inorganic anti-mite agent 13.15%, defoamer 0.3%, leveling agent 0.05%, anti-settling agent 1 %; The solid content of the first component is 55%.

[0064] The inorganic anti-mite agent is composed of borate, alkaline earth metal and silicate, and the particle size of the inorganic anti-mite agent is 15 μm;

[0065] The B component is composed of the following components in weight percentage: TDI trimer 45%, TDI adduct 30% butyl acetate 25%, and the solid content of the B component is 46%.

[0066] Wherein, the inorganic anti-mite agent adopts the inorganic anti-mite agent produced by SEGUROCERA.

[0067] The preparation method...

Embodiment 3

[0079] A kind of anti-mite oily PU transparent topcoat of the present embodiment, comprises A component and B component, and the weight ratio of described A component and described B component is 2: 1; Described A component consists of the following Component composition in weight percentage: high solid polyol resin 79%, lipid solvent 9%, dispersant 0.8%, inorganic anti-mite agent 5%, defoamer 0.5%, leveling agent 0.1%, anti-settling agent 4.4% %; The solid content of the first component is 58%.

[0080] The inorganic anti-mite agent is composed of borate, alkaline earth metal and silicate, and the particle size of the inorganic anti-mite agent is 10 μm;

[0081] The B component is composed of the following components in weight percentage: 40% of TDI trimer, 35% of TDI adduct, 25% of butyl acetate, and the solid content of the B component is 45%.

[0082] Wherein, the inorganic anti-mite agent adopts the inorganic anti-mite agent produced by SEGUROCERA.

[0083] Preferably, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com