Internal combustion engine and method of assessing the quality of motor oil in an internal combustion engine

A technology of internal combustion engine and engine oil, which is applied in the evaluation of the quality of engine oil in internal combustion engines and in the field of hybrid drive, and can solve the problems of high manufacturing consumption and cost, and the inability to integrate scientific instruments and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

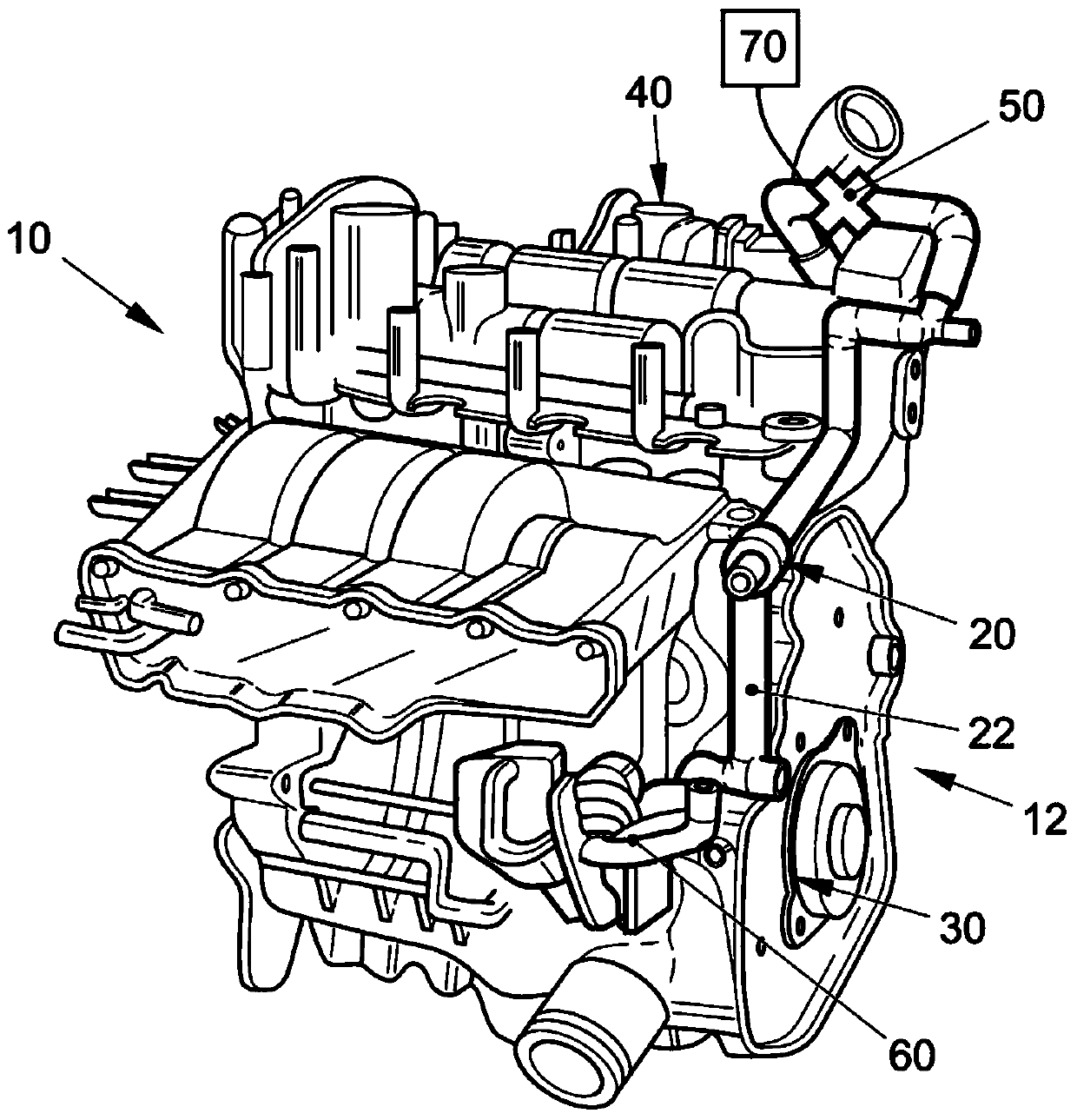

[0031] figure 1 The internal combustion engine 10 according to the invention in the form of a vehicle engine is shown and has a crankcase 12 with a crankcase ventilation device 20 for ventilating engine lubricating oil contained in an oil guide area 30 of the crankcase 12.

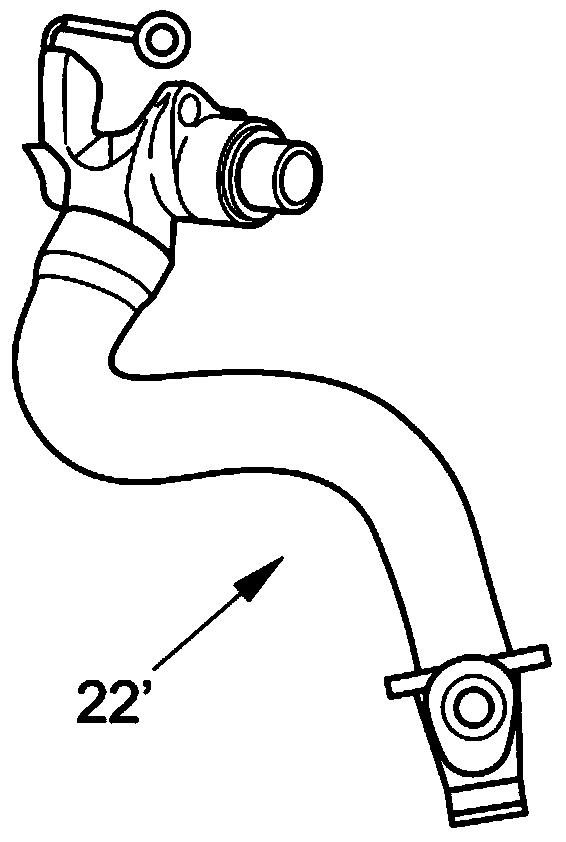

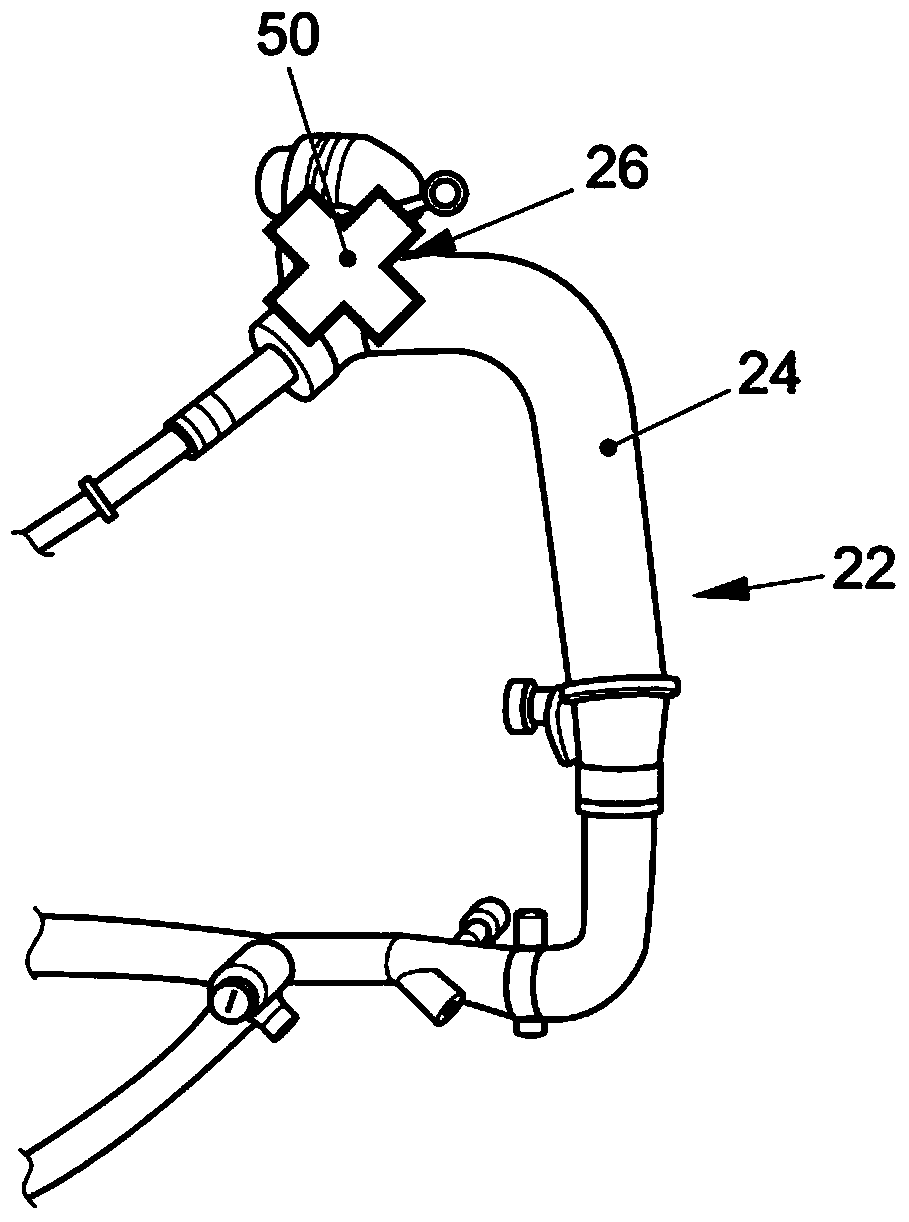

[0032] The crankcase ventilation device KGE 20 is designed as a closed crankcase ventilation device, in which the oil guide area 30 (power chamber) of the crankcase 12 is connected to the engine suction pipe 40 through the ventilation pipe 22. The blow-by gas containing fuel vapor (which enters the power chamber through the piston ring) can be led back to the suction pipe 40 through the ventilation pipe 22, so that the pressure in the power chamber 30 can be kept constant and the frequent occurrence of cold start of the engine can be eliminated Pollution of the engine oil.

[0033] A measuring sensor 50 is arranged in the ventilation duct 22 for measuring at least one characteristic value of the ventilation air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com