Waste gas treatment system and waste gas treatment method

A technology for waste gas treatment and waste gas treatment equipment, which can be used in gas treatment, separation methods, chemical instruments and methods, etc., and can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

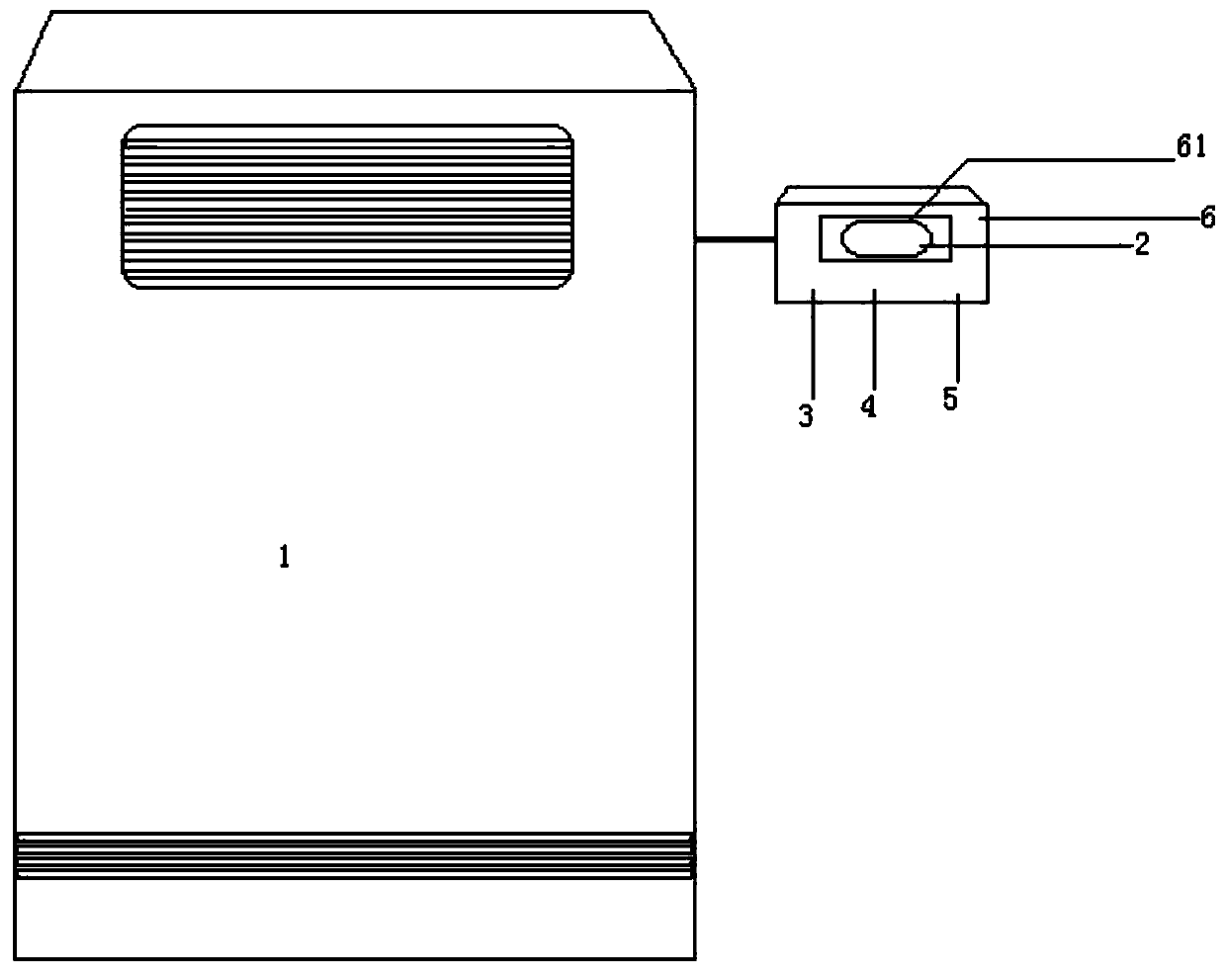

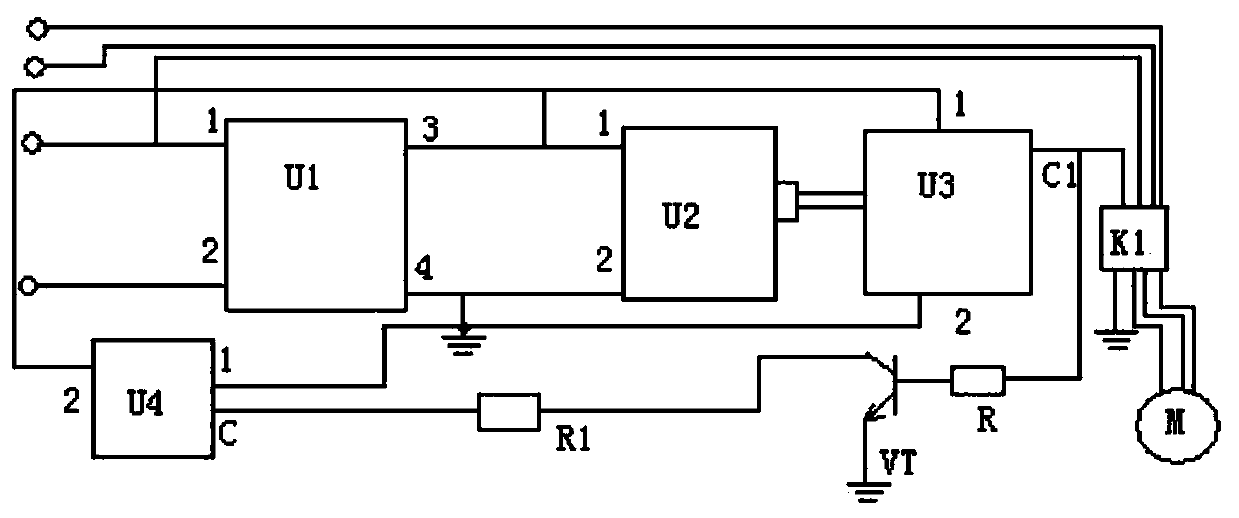

[0018] figure 1 As shown in , an exhaust gas treatment system includes an exhaust gas treatment equipment body 1, a benzene and xylene detector body 2, a single-chip microcomputer module 3, a switching power supply 4, and a short message sending circuit 5, a single-chip microcomputer module 3, a switching power supply 4, and a short message The sending circuit 5 is installed on the circuit board, the circuit board and the benzene and xylene detector body 2 are installed in the component box 6, and the component box 6 is installed in the electrical control box of the production area or office area, etc., the benzene and xylene detector The detection head of the main body 2 is located at the rear end of the opening 61 in the front middle of the component box. The power input terminal of the switching power supply 4 and the two poles of the 220V AC power supply are respectively connected by wires, and the positive and negative poles of the power output terminal of the switching po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com