A method for measuring the current efficiency of an electrolyzer on-line and its realization device

A current efficiency, electrolytic cell technology, applied in the field of online measurement of electrolytic cell current efficiency, to achieve the effect of no need for capital investment, optimization of technical conditions and parameters, and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in detail below in conjunction with the examples.

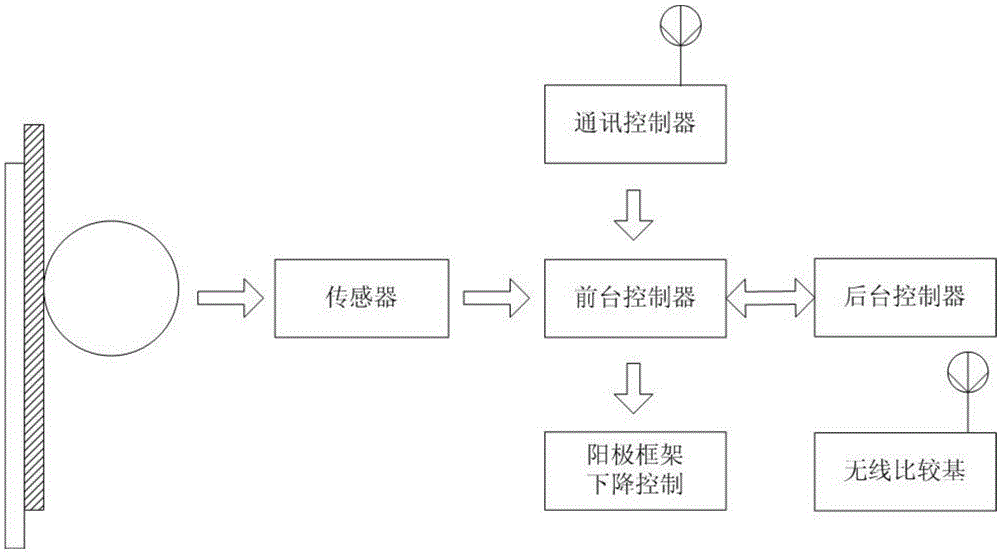

[0018] The present invention is applicable to various anode height measuring devices and supporting crown crane accessories, and is applicable to various aluminum electrolytic cell types. The design takes 15 days as a time period, and the anode level in the initial state of the measurement period is used as the standard basis. Through the measurement of the change of the anode level after the aluminum is tapped every day in the period as a comparison base, the standard base is set to a fixed value of 1, and the daily comparison base is compared with the standard base for calculation, based on the average calculation results of 15 days Draw the change curve of the anode level, combined with the daily aluminum output in the cycle, calculate the current efficiency through the core algorithm of the present invention, the specific method is as follows:

[0019] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com