Fresh pteroceltis tatarinowii bark processing system

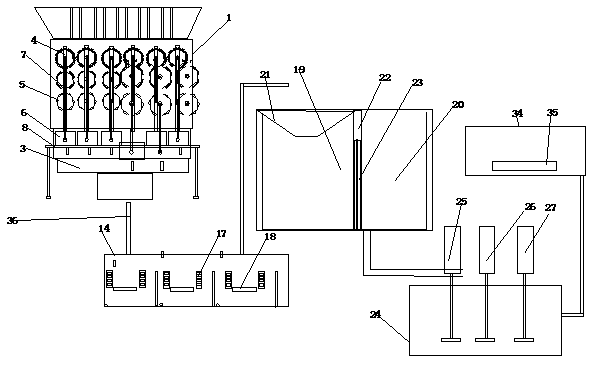

A processing system, green sandalwood technology, applied in the direction of textiles and papermaking, fiber raw material processing, etc., can solve the problems of difficult control of processing quality, pollution of processing steps, low output, etc., and achieve the effect of increasing strength, simple combination, and enhancing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

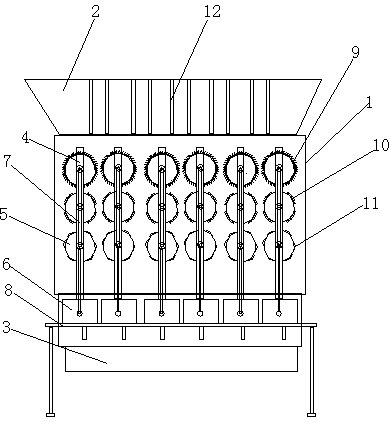

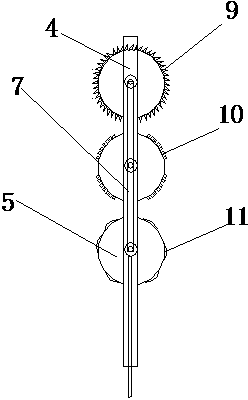

[0022] like figure 2 Shown, described fresh green sandalwood bark sorting unit: comprise cabinet 1, described cabinet 1 top is provided with feeding chute 2, and described cabinet 1 bottom is provided with discharge opening 3, in described cabinet 1 There are many groups of green sandalwood carding devices, and the green sandalwood carding device includes a connecting rod 4 arranged on the cabinet, a plurality of rollers 5 arranged on the connecting rod 4, and a combing sleeve arranged on the rollers 5 Group, and the driving motor unit 6 and the driving belt 7 that drive each group of rollers to rotate. Specifically, at least three rollers are arranged on the connecting rod 4 .

[0023] like image 3 As shown, further, the carding set on the roller 5 includes from top to bottom: a sorting carding set 8 , a pressure collecting carding set 9 , and a flat pressing carding set 10 . Specifically, the sorting teeth on the sorting and carding sleeve 8 are in an inverted triangle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com