Method for directly preparing low-carbon alcohol and co-producing gasoline through CO2 hydrogenation

A low-carbon alcohol, direct technology, applied in the direction of chemical instruments and methods, preparation of hydroxyl compounds, organic compounds, etc., can solve the problem of low activity of low-carbon alcohols, achieve high conversion rate of CO2, novel reaction process, combination method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

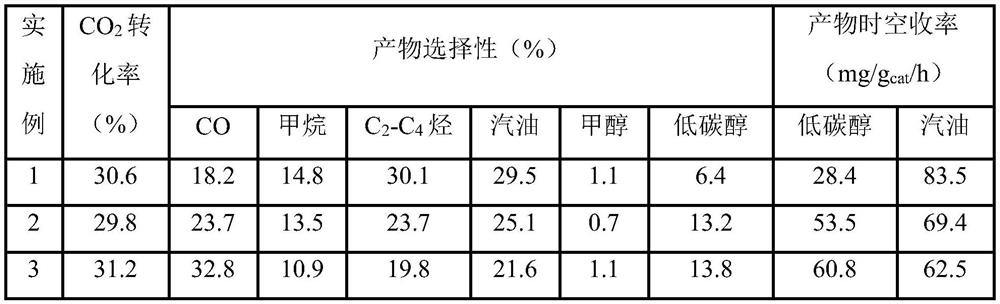

[0027] Fixed K accounts for CuO-MgO-ZnO-Fe 2 o 3 3% of the total mass, changing the Mg / Zn molar ratio, preparing three catalysts K 2 O-CuO(1)-MgO(2)-Fe 2 o 3 (1), K 2 O-CuO(1)-MgO(1.8)-ZnO(0.2)-Fe 2 o 3 (1), K 2 O-CuO(1)-MgO(1.5)-ZnO(0.5)-Fe 2 o 3 (1), brackets are molar ratios, and its catalytic test performance is as shown in Table 1, corresponding to Examples 1-3 respectively.

[0028] Catalytic test conditions: take 0.5g of catalyst and 1.0g of quartz sand, mix the catalyst in H2 / Ar atmosphere at 350°C for 2 hours, then cooled to 320°C, filled with 5MPa CO 2 / H 2 Mixed gas, and activated at a gas flow rate of 50mL / min for 3h, then at 320°C, 5MPa, 6000mL / g cat Start CO under the condition of / h 2 hydrogenation reaction.

[0029] The catalytic test performance data of table 1 embodiment 1-3

[0030]

[0031] As can be seen from the data in Table 1, when only containing Mg and not containing Zn, the gasoline space-time yield is higher, but the low-carbon alc...

Embodiment 4-7

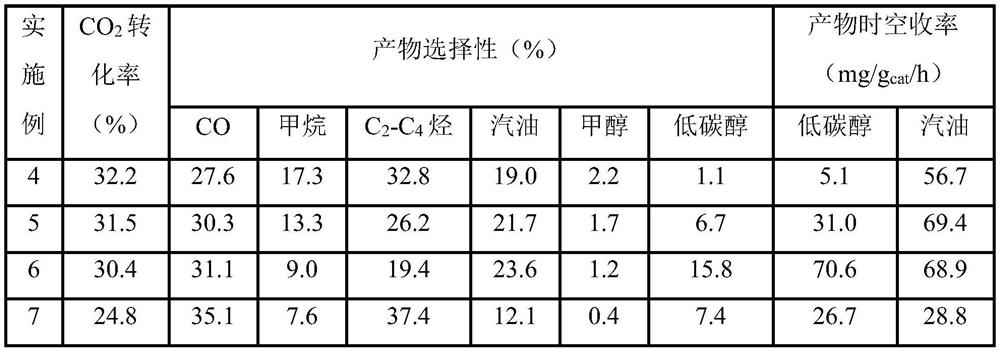

[0033] Fixed CuO(1)-MgO(1.5)-ZnO(0.5)-Fe 2 o 3 (1), change K to account for CuO(1)-MgO(1.5)-ZnO(0.5)-Fe 2 o 3 The mass percentage of (1), the preparation K content is respectively four catalysts of 0.1%, 1.4%, 4.6%, 17.6%, and its catalytic test performance is as shown in Table 2, respectively corresponds to example 4-7. Catalytic test conditions: take 0.5g of catalyst and 1.0g of quartz sand, mix the catalyst in H 2 / Ar atmosphere at 350°C for 2 hours, then cooled to 320°C, filled with 5MPa CO 2 / H 2 Mixed gas, and activated at a gas flow rate of 50mL / min for 3h, then at 320°C, 5MPa, 6000mL / g cat Start CO under the condition of / h 2 hydrogenation reaction.

[0034] Table 2 embodiment 4-7 catalytic test performance data

[0035]

[0036] As can be seen from the data in Table 2, when the K content was 1.4% and 4.6% respectively, the yields of low-carbon alcohol and gasoline were good, and when the K content was too low, the yield of low-carbon alcohol decreased signi...

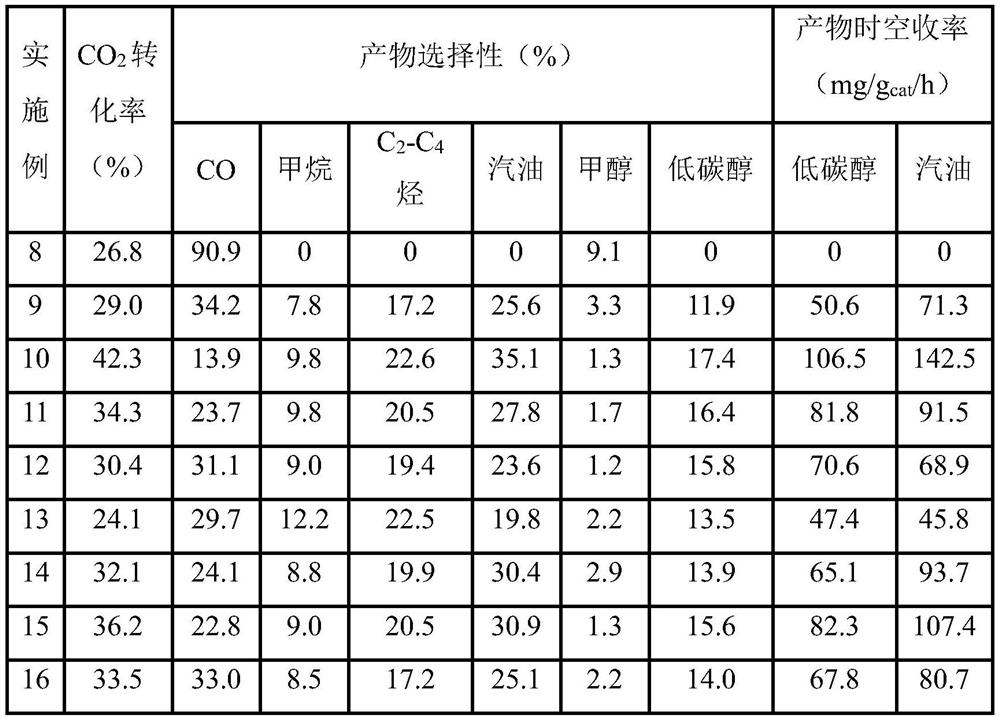

Embodiment 8

[0038] Take 0.5g CuO-ZnO-Al 2 o 3 The catalyst is mixed with 1.0g of quartz sand, and the catalyst is 2 / Ar atmosphere at 350°C for 2 hours, then cooled to 320°C, filled with 5MPa CO 2 / H 2 Mixed gas, and activated at a gas flow rate of 50mL / min for 3h, then at 320°C, 5MPa, 6000mL / g cat Start CO under the condition of / h 2 hydrogenation reaction. The product was detected by gas chromatography, and the specific catalytic performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com