A segmented gob-side entry retention method in fully mechanized mining/caving face

A technology for mining working face and empty entry retaining, applied in mining equipment, earthwork drilling, filling and other directions, can solve the problems affecting the smooth discharge of gas in the upper corner, large auxiliary transportation workload, and high labor intensity of workers, etc. Wide practicability, convenient construction, and small auxiliary transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

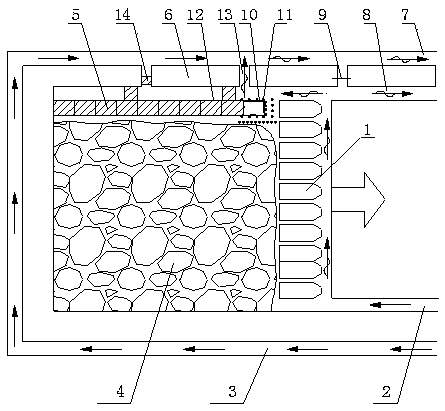

[0016] An embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing:

[0017] like figure 1 As shown, the segmented gob-side entry retention method of the fully mechanized mining / caving working face of the present invention includes arranging the air inlet lane 2 and the air return lane 8 on both sides of the mining face, the outer air inlet lane 3 and the outer air return airway Lane 7, the return air lane 8 and the outer ring return air lane 7 are left with coal pillars 6, and the following steps are also included:

[0018] a. In the coal mine underground roadway, with the advancement of the mining face, the anchor rod or anchor cable is driven between the end hydraulic supports 1 of the mining face or at the roof behind the end hydraulic support 1;

[0019] b. Reinforced mesh 12 is erected behind the end hydraulic support to assist the filling body to form and reinforce the filling body, hang the filling bag 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com