Marine turbocharger bearing body with rotation stopping function

A turbocharger and bearing body technology, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of the engine not working, etc., and achieve the effect of easy start-up, uniform force, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

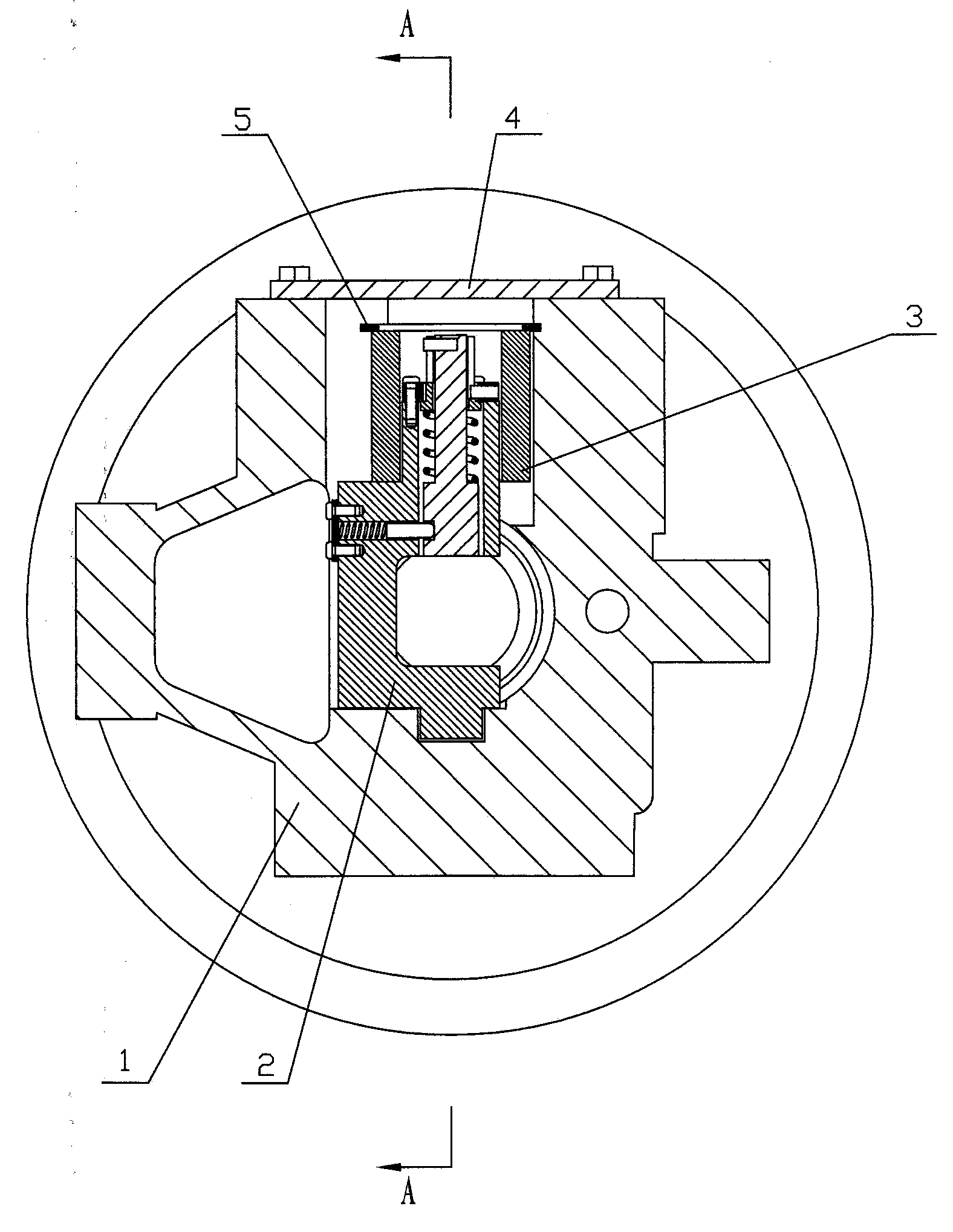

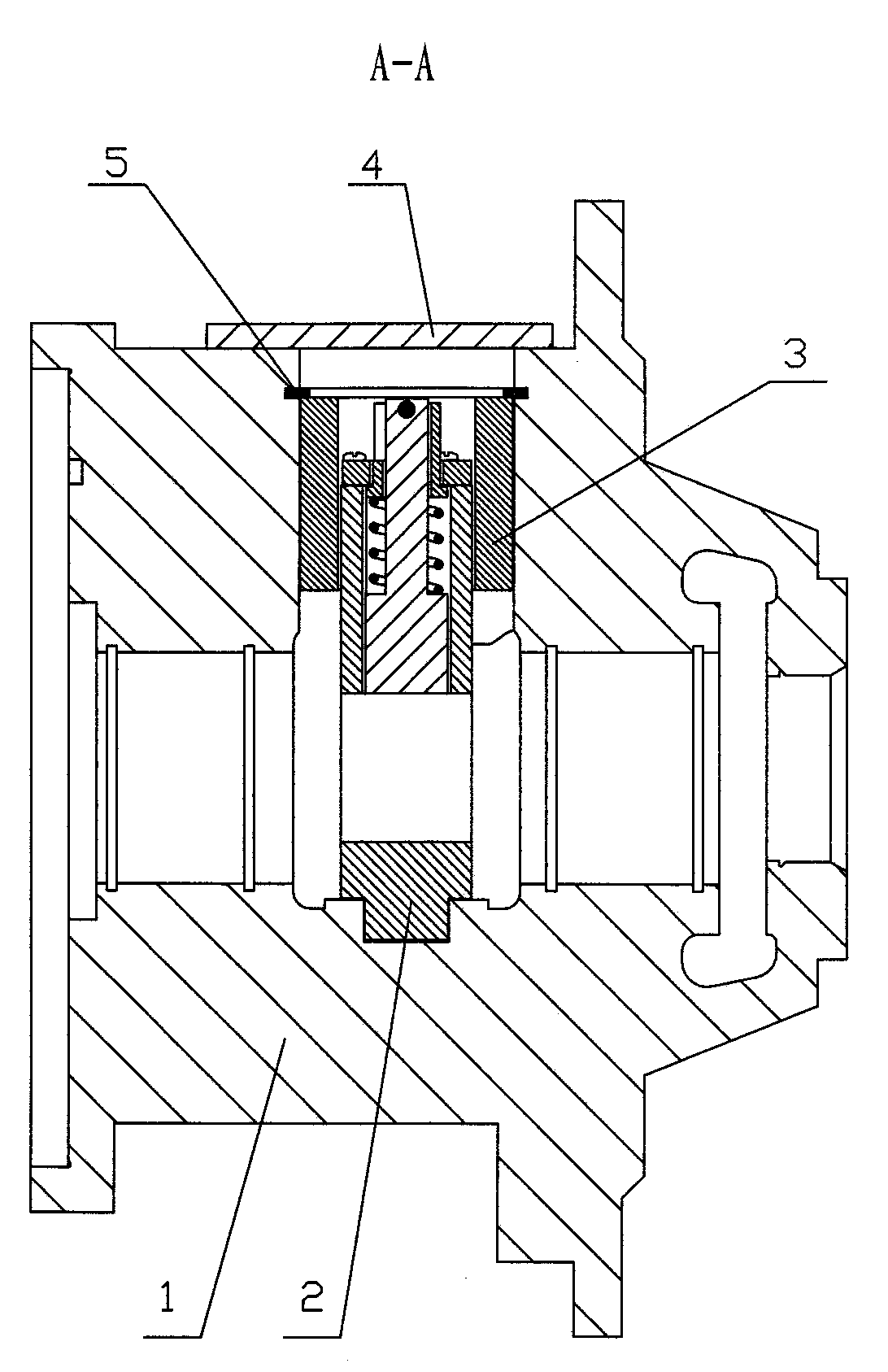

[0032] A marine turbocharger bearing body with anti-rotation function comprises a bearing body 1, an anti-rotation device 2, an anti-rotation sleeve 3, a sealing cover plate 4 and an elastic anti-rotation retaining ring 5.

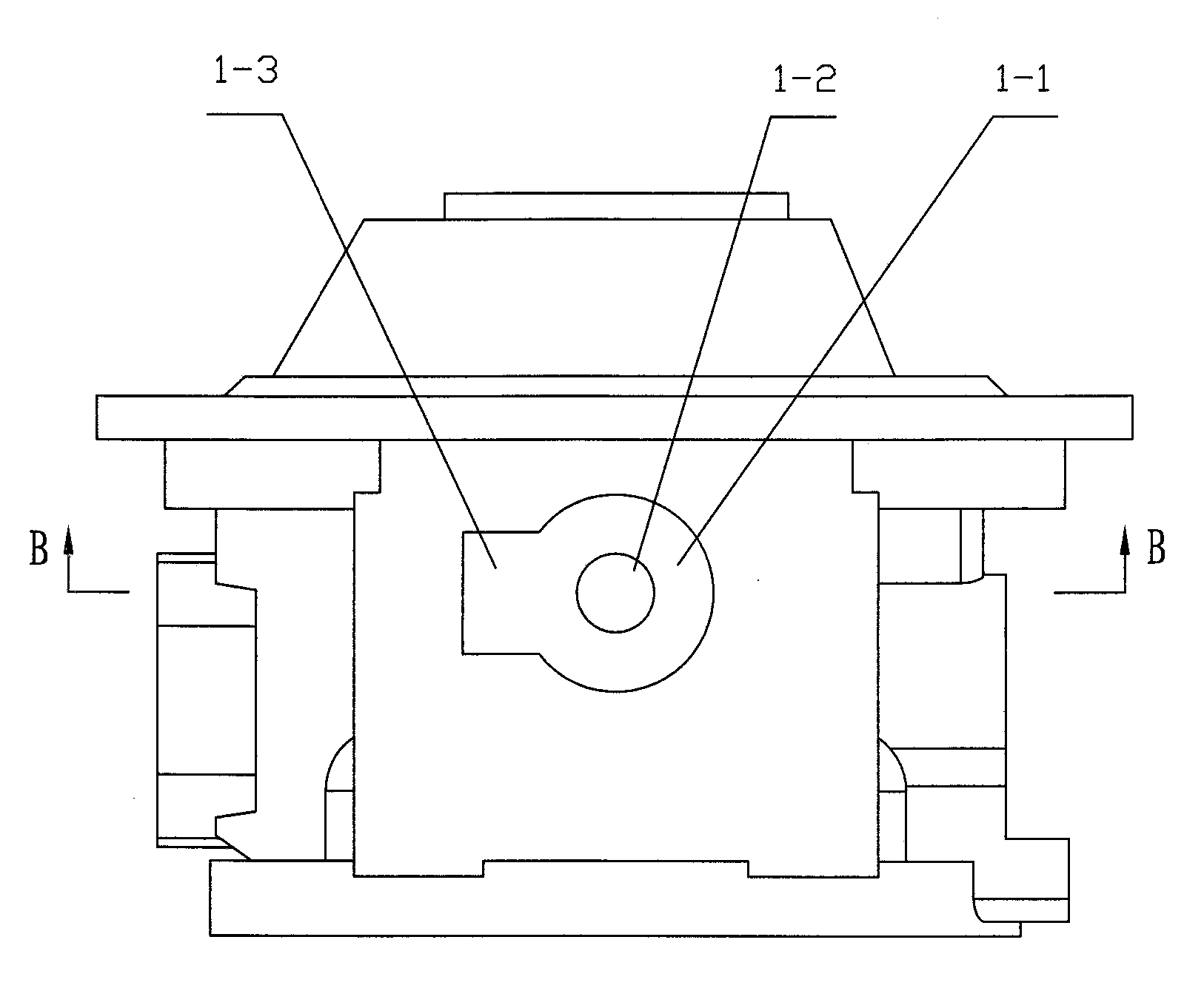

[0033] The bearing body 1 is provided with a first anti-rotation device installation hole 1-1 and a second anti-rotation device installation hole 1-2, and the first anti-rotation device installation hole 1-1 and the second anti-rotation device installation hole 1 -2 is located between the two floating bearing installation holes of the bearing body 1, the first anti-rotation device installation hole 1-1 and the second anti-rotation device installation hole 1-2 are on the same axis, and are on the bearing body 1 The axes of the two floating bearing mounting holes are vertical, and the inner wall of the first anti-rotation device mounting hole 1-1 is provided with a mounting notch 1-3 and a retaining ring groove 1-4.

[0034] The anti-rotation device 2 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com