A compact, versatile high-pressure pump

A high-pressure pump, multi-purpose technology, applied to the components, pumps, pump elements, etc. of the pumping device for elastic fluid, can solve the problem of unreasonable structural design of the discharge valve and the liquid inlet valve, and no space for forced cooling system added. , The volume of the high-pressure pump should not be too large, so as to achieve the effect of improving the heat dissipation effect, simple structure and small resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The small-volume, multi-purpose high-pressure pump provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

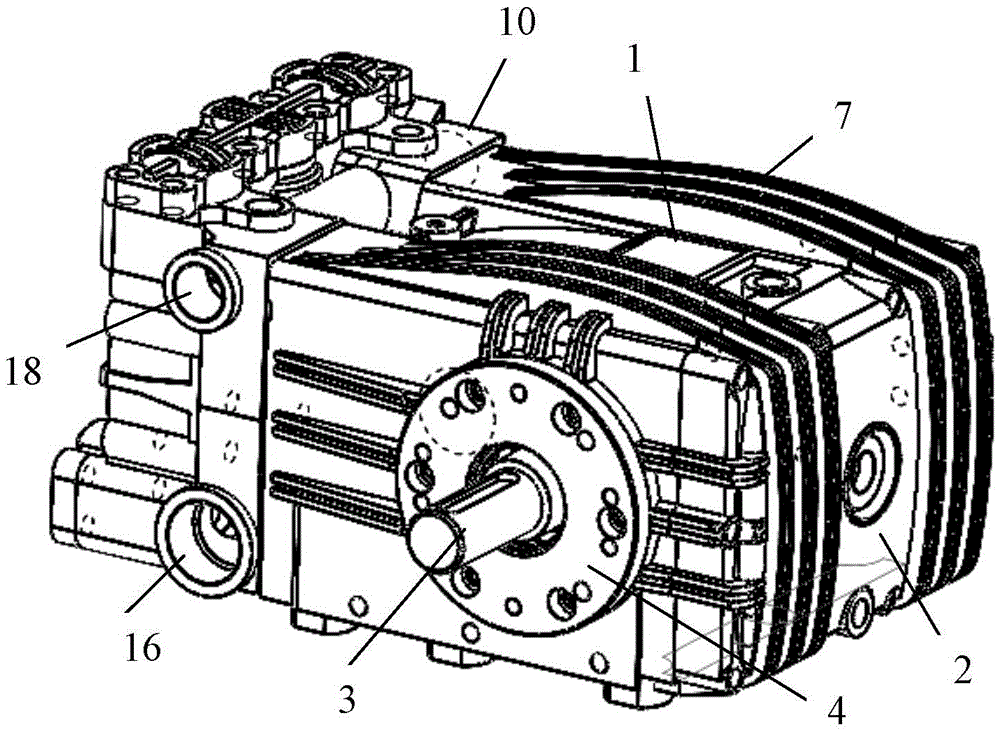

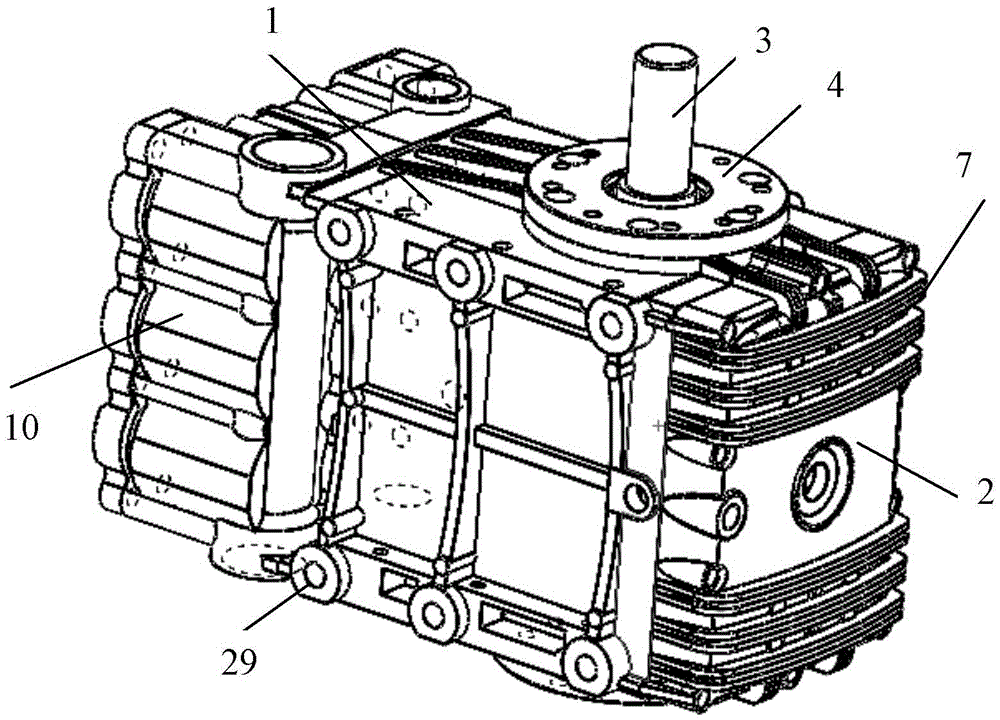

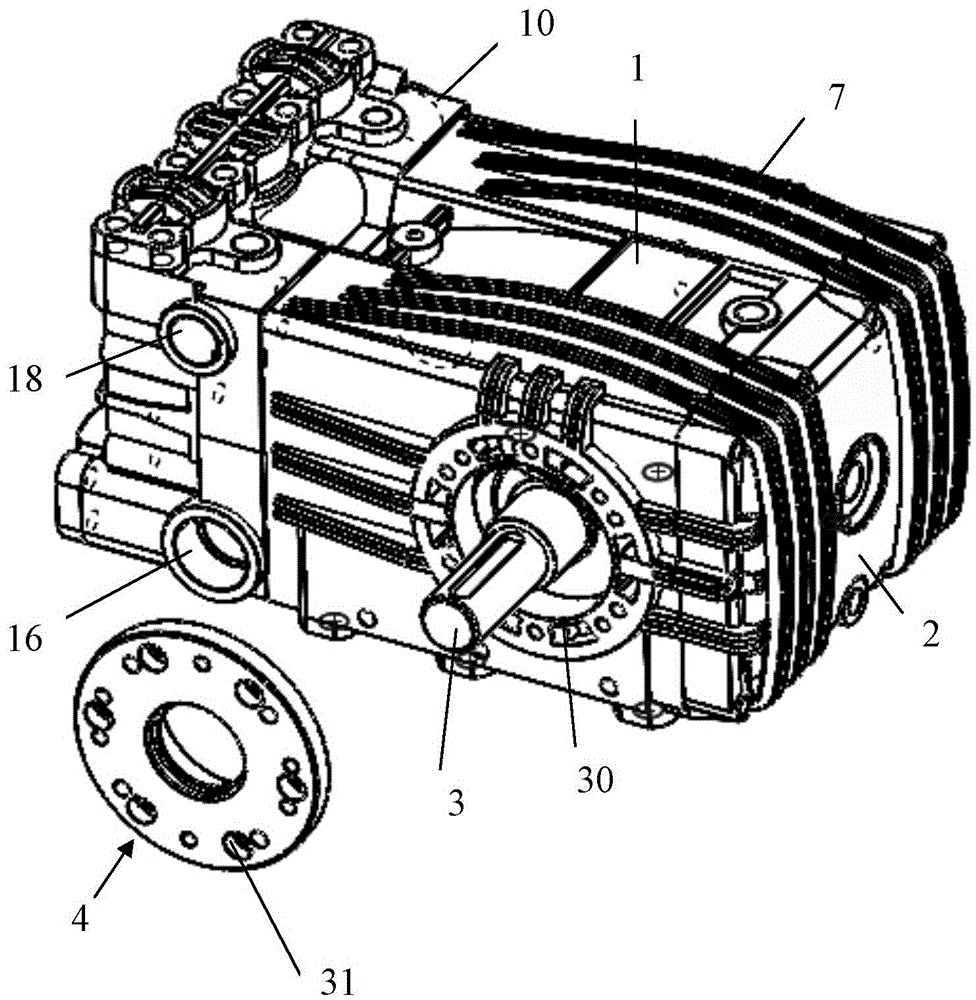

[0028] Such as figure 1 — Figure 9 As shown, the small and multipurpose high-pressure pump provided by the present invention is composed of a power end and a hydraulic end, wherein the power end includes a crankcase 1, a rear cover 2, a crankshaft 3, a crankshaft end cover 4, and a plurality of connecting rods 5 and an integrated middle rod 6; the middle part of the bottom surface of the crankcase 1 is inwardly recessed, and the rear end is formed with an opening; the rear cover 2 covers the rear end opening of the crankcase 1, and the crankcase 1 and the rear cover 2 have multiple Strip cooling fins 7; the crankshaft 3 is horizontally arranged inside the crankcase 1, and one end runs through the side wall of the crankcase 1 and extends to the outside, and this end is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com