Pump device

A technology of pump device and drive device, applied in pump control, liquid variable capacity machinery, machine/engine, etc., to achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

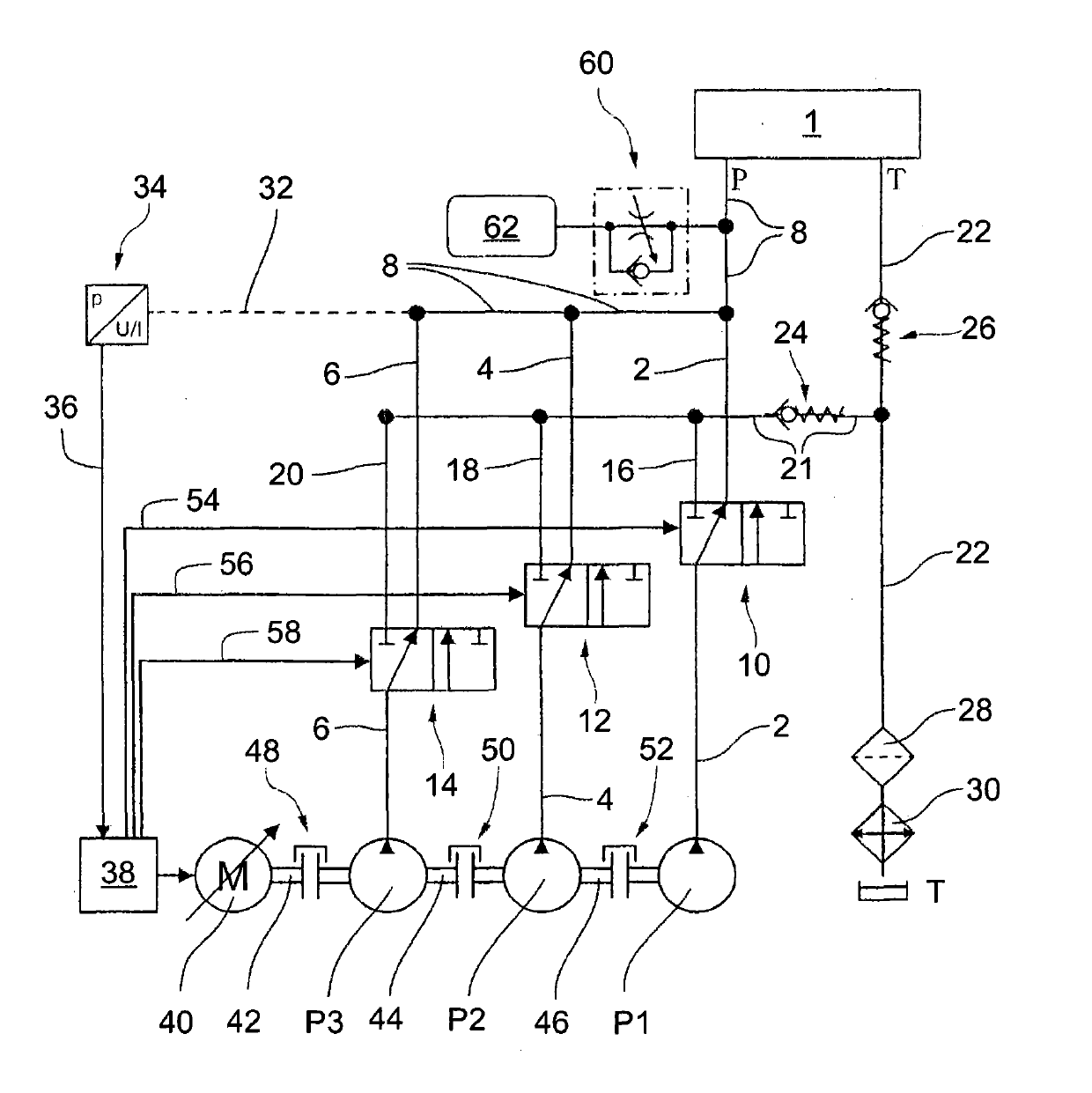

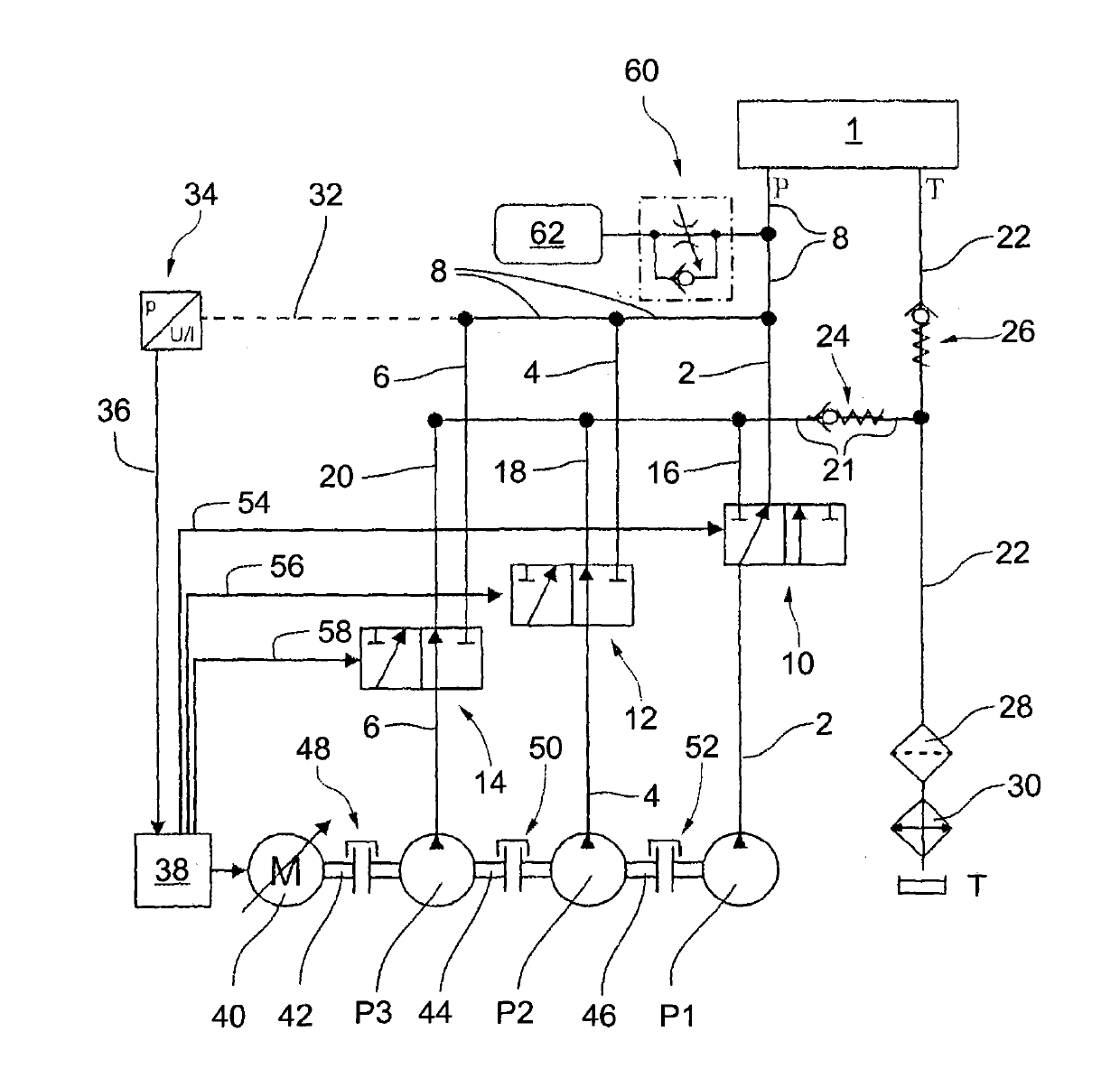

[0033] figure 1 An exemplary embodiment of the pump device according to the invention is shown in the case of a maximum volumetric flow requirement of a load 1 connected to the pump device, which is designed as a constant pressure system. The pump arrangement has three metering pumps P1 , P2 , P3 connected in parallel. They are arranged in an open loop and have working lines 2, 4, 6 respectively. The working lines 2 , 4 , 6 feed into a common high-pressure line 8 , via which the load 1 is supplied with pump pressure.

[0034] The three metering pumps can have different nominal delivery volumes, according to which a distinction is made below between the large metering pump P3 , the middle metering pump P2 and the small metering pump P1 . The small fixed displacement pump P1 is designed for zero-stroke operation or pressure-maintained drive.

[0035] Distribution valves 10 , 12 , 14 are provided in the working lines 2 , 4 , 6 respectively. Each distribution valve 10, 12, 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com