Anti-blocking throw-in type draining pump of coal-bed gas well

A technology for coalbed methane wells and drainage pumps, which is applied to drainage, pump components, variable capacity pump components, etc., can solve the problems of heavy workload and high cost, reduce the probability of pump jamming, reduce wear, and prevent pistons from being damaged. card effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

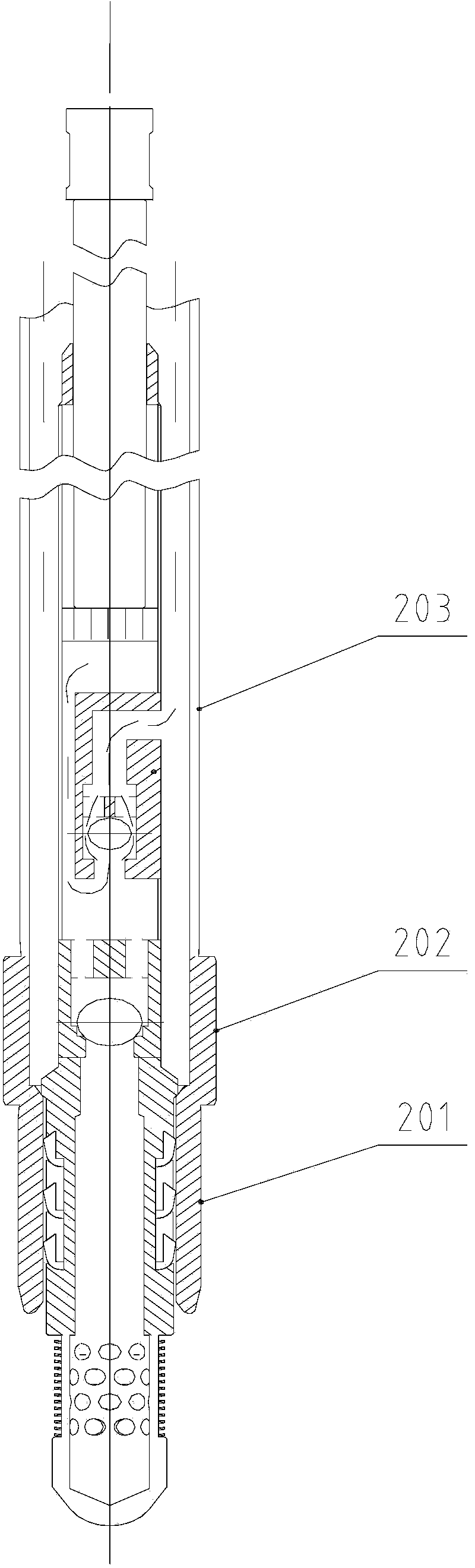

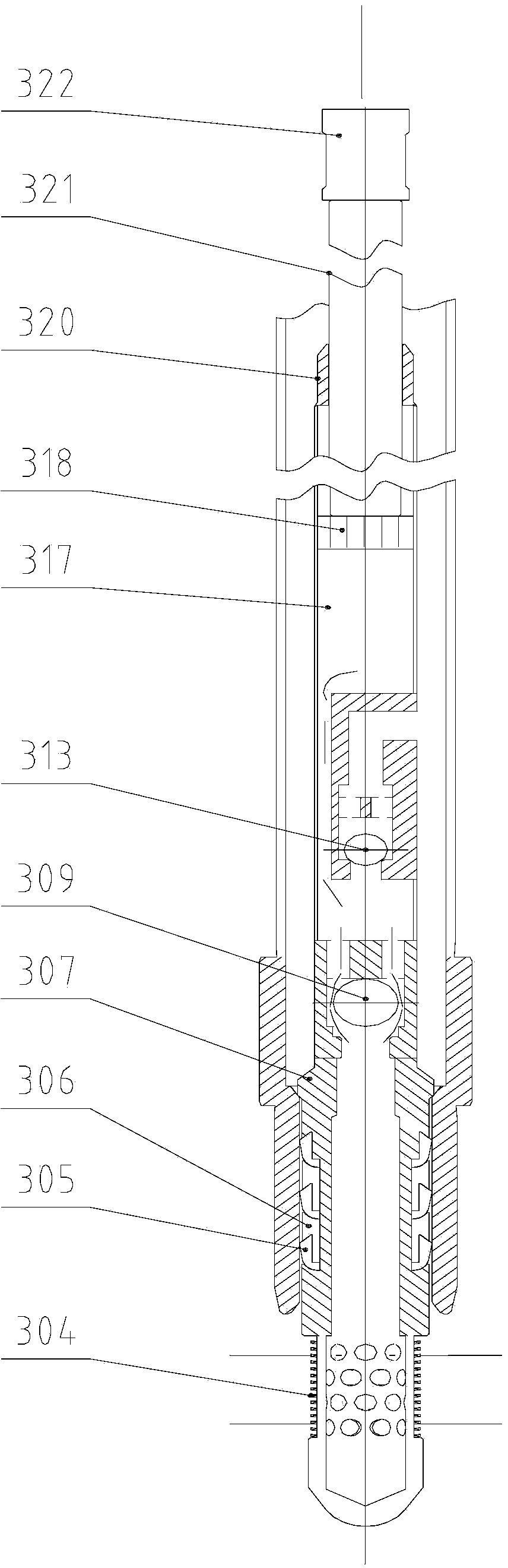

[0019] The invention provides a coalbed gas well anti-jamming and throwable drainage pump. The coalbed gas well anti-jamming and fishing drainage pump provided by the invention uses the full stroke of the outer circle of the piston to seal and cooperate with the inner circle of a part of the cylinder.

[0020] Simultaneously, in order to avoid the accumulation of pulverized coal on the top of the cylinder, the present invention is provided with an inclined surface or a conical surface on the top of the cylinder, which can remove the pulverized coal on the piston rod during the stroke.

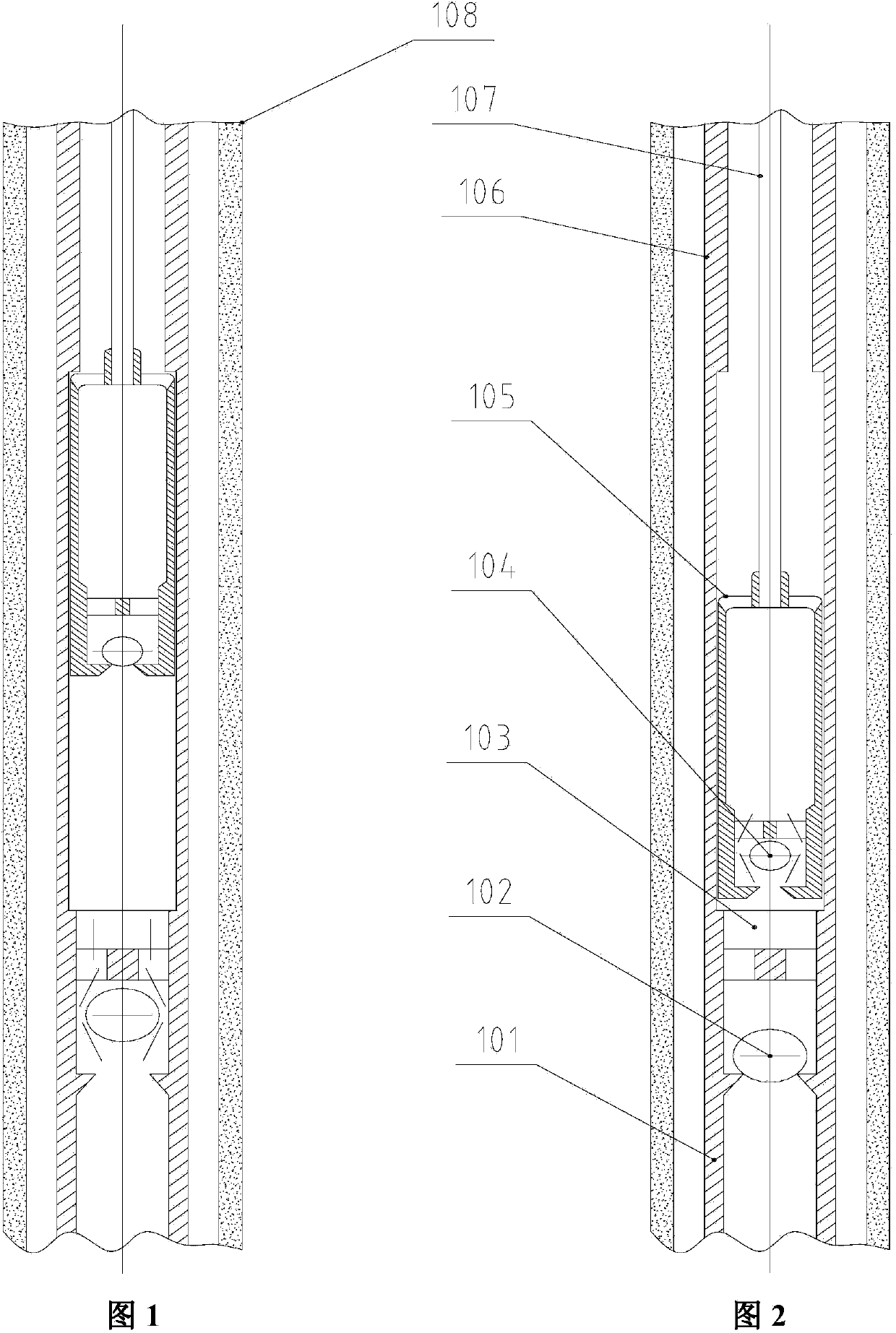

[0021] see figure 1 and figure 2 , shows a prior art drain pump, which adopts a combined structure of a fixed valve 102 and a floating valve 104 . The bottom 101 of the fixed valve 102 is fixed on the lower end of the oil pipe 106 . The stationary valve 102 can thus remain stationary at the bottom of the well 108 during operation. The floating valve 104 in the prior art pump is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com