Asphalt mixture life prediction method considering fatigue-creep interaction damage effect

A technology for asphalt mixture and life prediction, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, and can solve problems such as application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

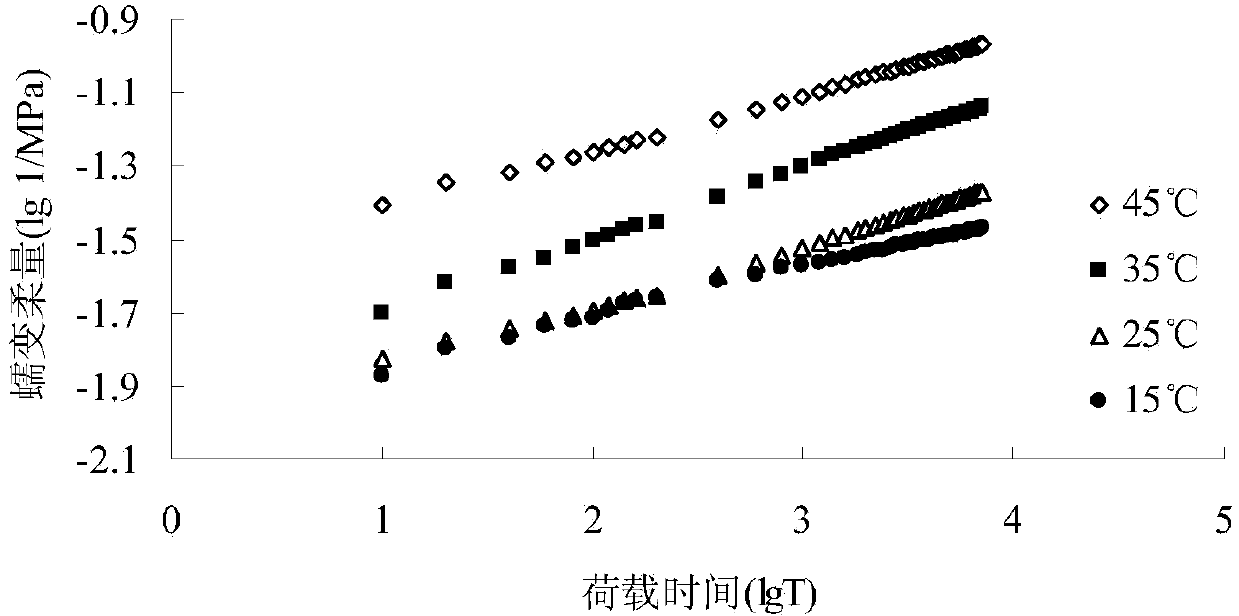

[0068] Example 1 (asphalt mixture AC-13):

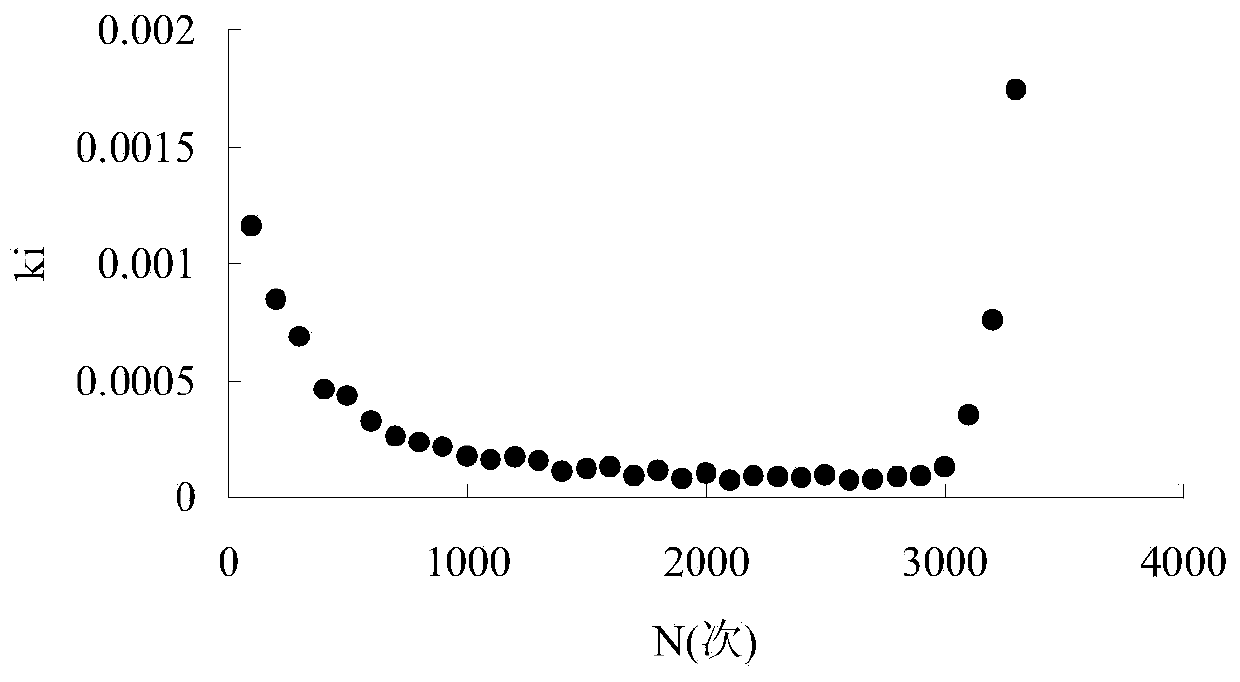

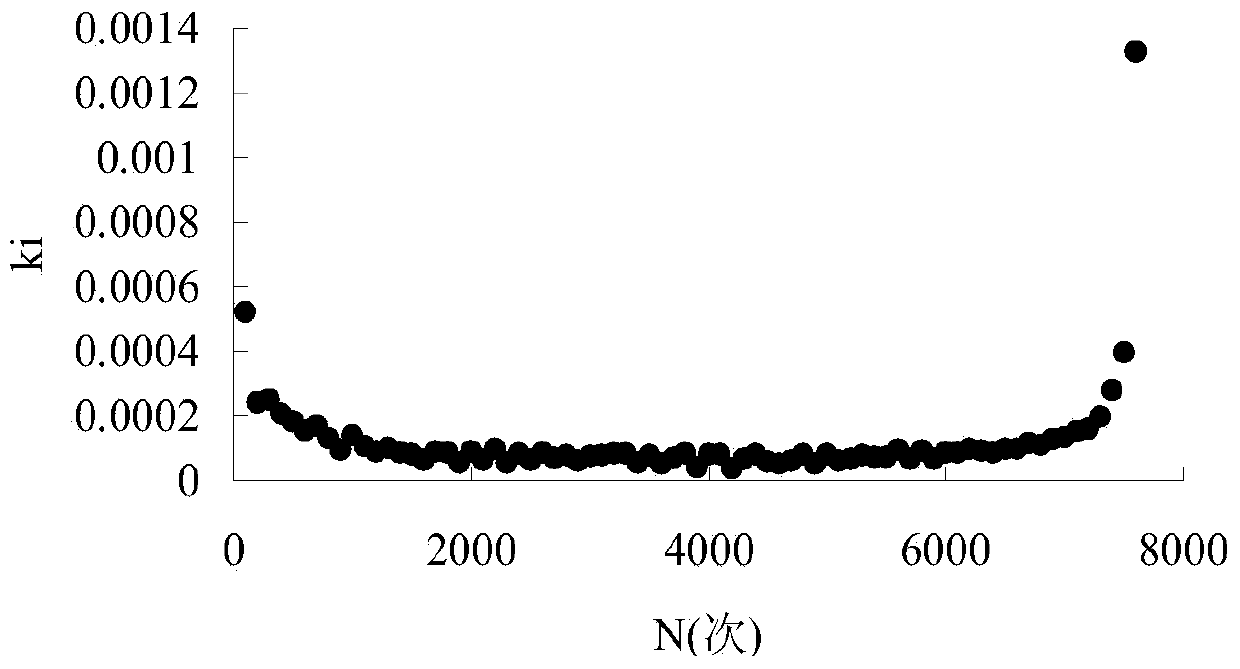

[0069] (1) Determine the complex modulus of asphalt mixture under cyclic loading

[0070] This test uses a testing machine produced by Cooper Research Technology Co., Ltd., which is equipped with high-precision mechanical sensors and displacement sensors. The data that can be recorded automatically include: loading times, stress value, strain value, complex modulus, modulus percentage, hysteresis angle, dissipation energy, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com