Computing method for flow simulation in self-priming process of self-priming pump

A technology of flow simulation and calculation method, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of deviation, can not replace the test method well, can not simulate calculation, optimize and design self-priming pumps, etc., to achieve savings The effect of investment of money and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

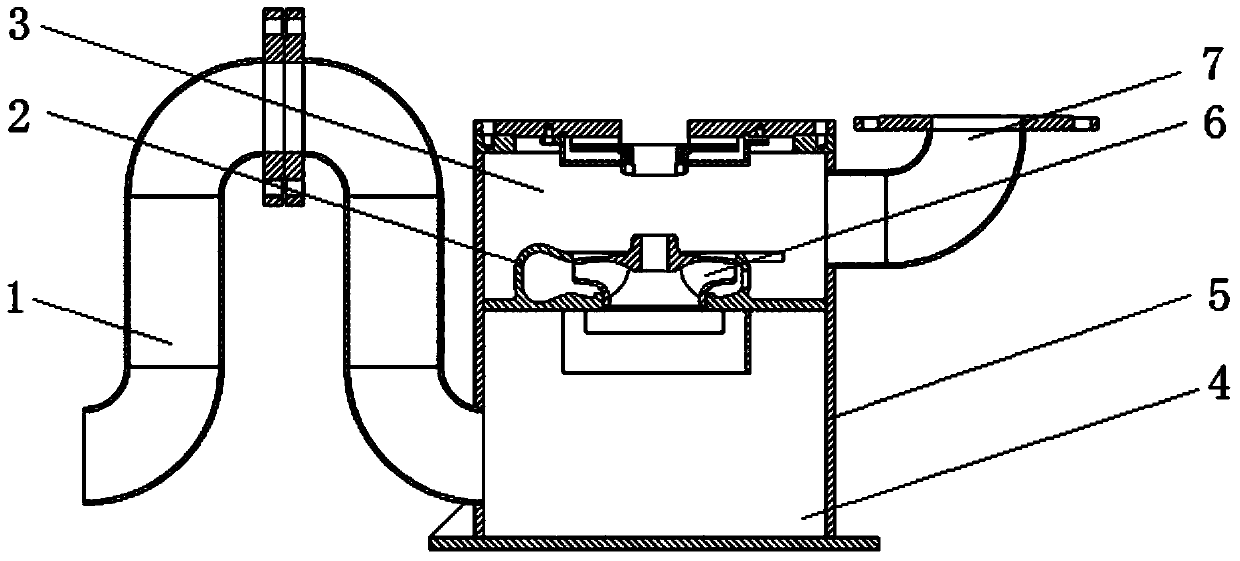

[0021] like figure 1 As shown, a commonly used vertical external mixing self-priming centrifugal pump is selected as the research object, and Pro / E is used to carry out three-dimensional solid modeling of the flow domain of the self-priming pump, and import it into ICEM for structural / non-structural grid unit division , The vertical external mixing self-priming centrifugal pump includes a water inlet pipe 1, a volute 2, a gas-liquid separation chamber 3, a liquid storage chamber 4, a pump body 5, an impeller 6 and a water outlet pipe 7.

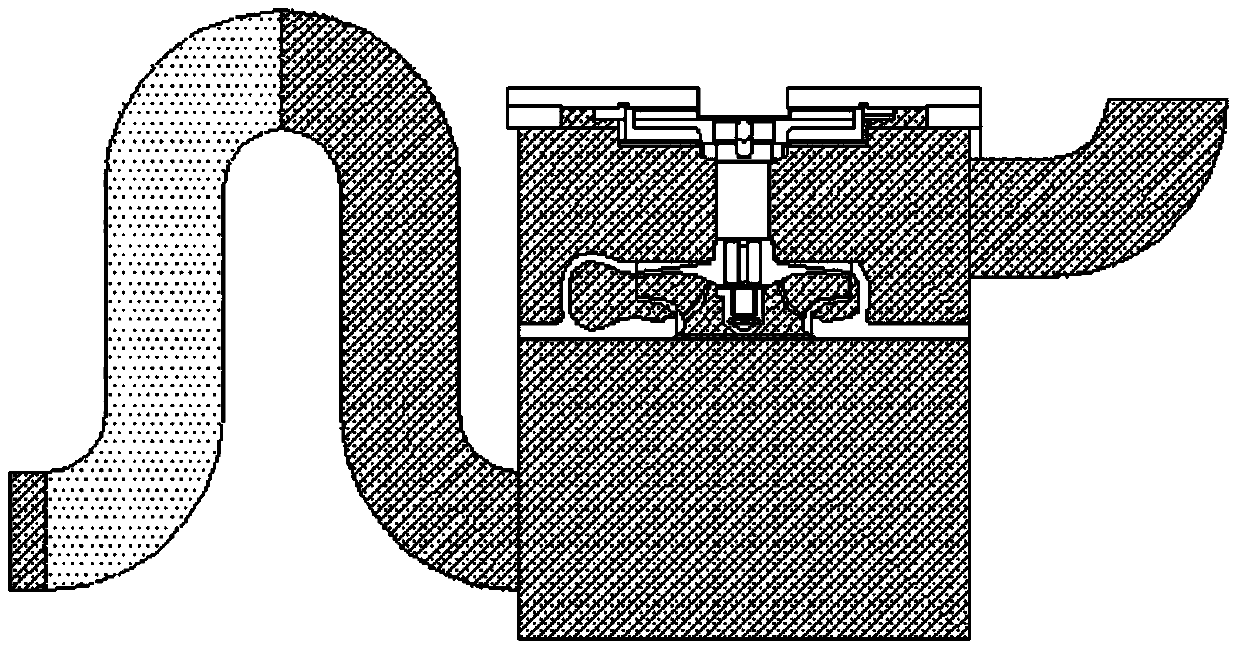

[0022] like figure 2 As shown, water and air at 25°C are selected as the liquid phase and gas phase respectively, and the settings close to the real self-priming situation are adopted (that is, a section of the water inlet pipe 1 is selected to be filled with gas as the initial condition for calculation), and the self-priming process is regarded as an isothermal process. Outlet boundary conditions are set in terms of pressure.

[0023] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com