socket connector

A socket connector and through-hole technology, which is applied in the field of socket connectors, can solve the problems of potential difference, high-frequency signal leakage, complex mold structure, etc., and achieve the effects of increased grounding connection positions, reliable electromagnetic shielding, and reliable electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

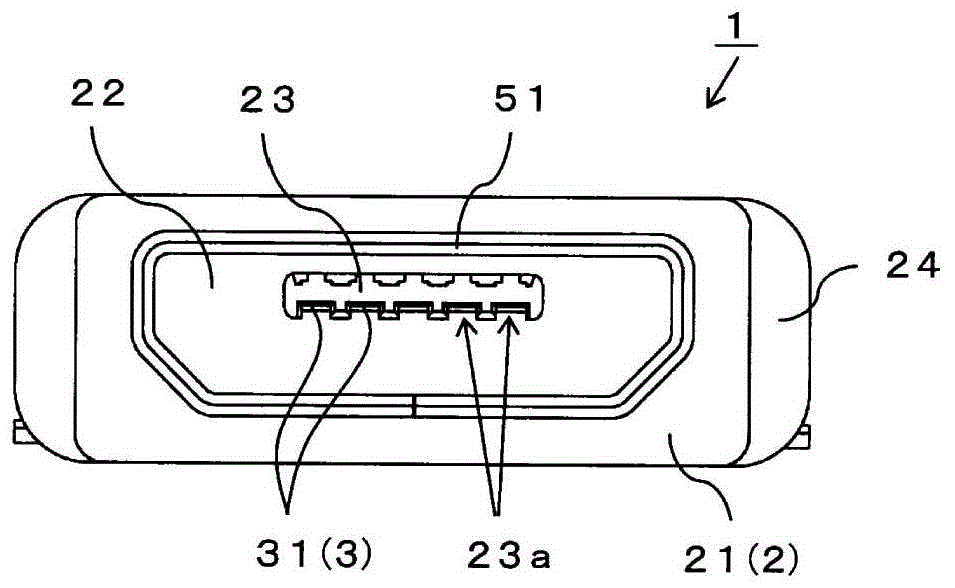

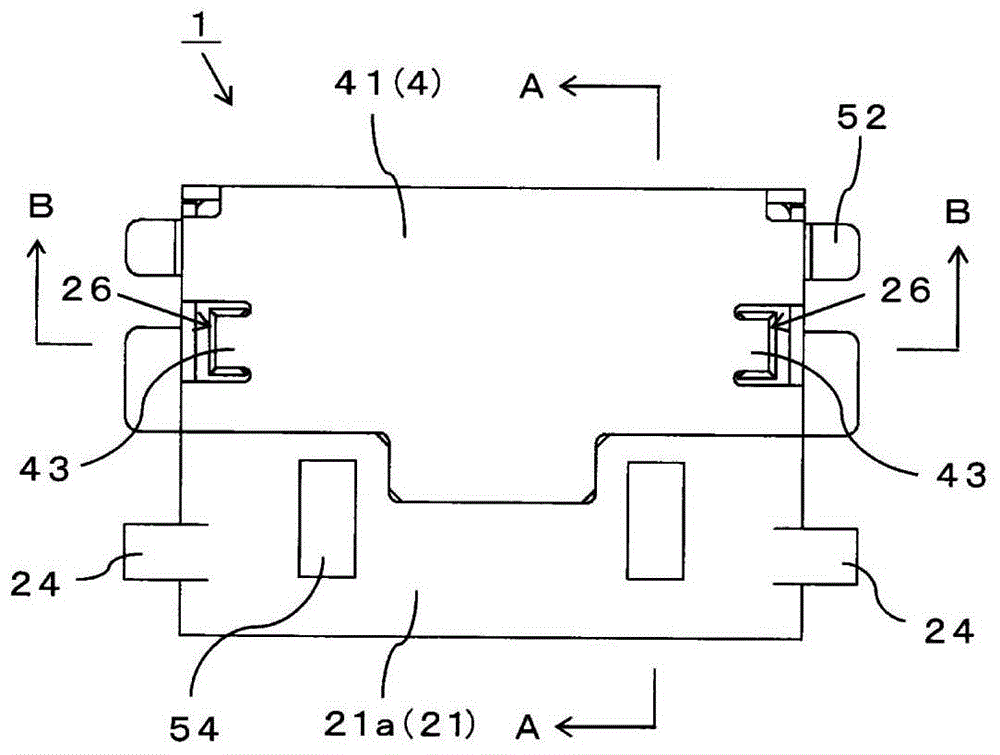

[0055] Below, use Figure 1 to Figure 9 A receptacle connector 1 according to one embodiment of the present invention will be described in detail. Socket connector 1 with slave figure 1 The unillustrated mating plug inserted in the front side shown is connected. In the following, the description of each part of the receptacle connector 1 takes the connection direction with the mating plug as the front. figure 2 In the plan view of , the lower part is referred to as the front, the upper part is referred to as the rear, and the left-right direction is referred to as the left-right direction.

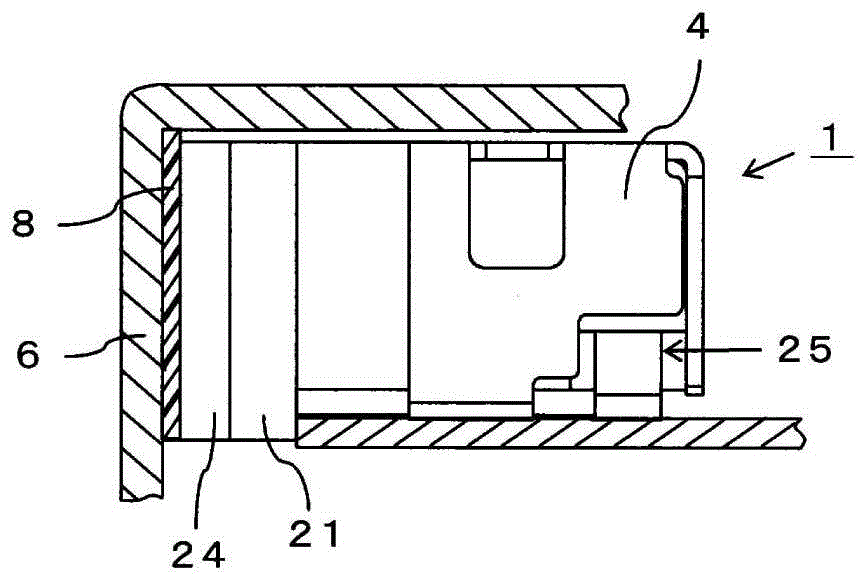

[0056] As shown in these figures, the receptacle connector 1 includes an insulating shell 2, a shielding shell metal part 5 integrally mounted on the insulating shell 2, and a plurality of contacts 3, and a plurality of contacts 3 installed along the rear plane and two sides of the insulating shell 2. Shield 4.

[0057] Such as Figure 6 As shown, the shielding case metal fitting 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com