Silkworm cocoon peeling machine

A technology of stripping machine and silkworm cocoon, applied in animal husbandry and other directions, can solve the problems of high labor intensity, difficult operation and time-consuming, and achieve the effect of reducing labor intensity, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

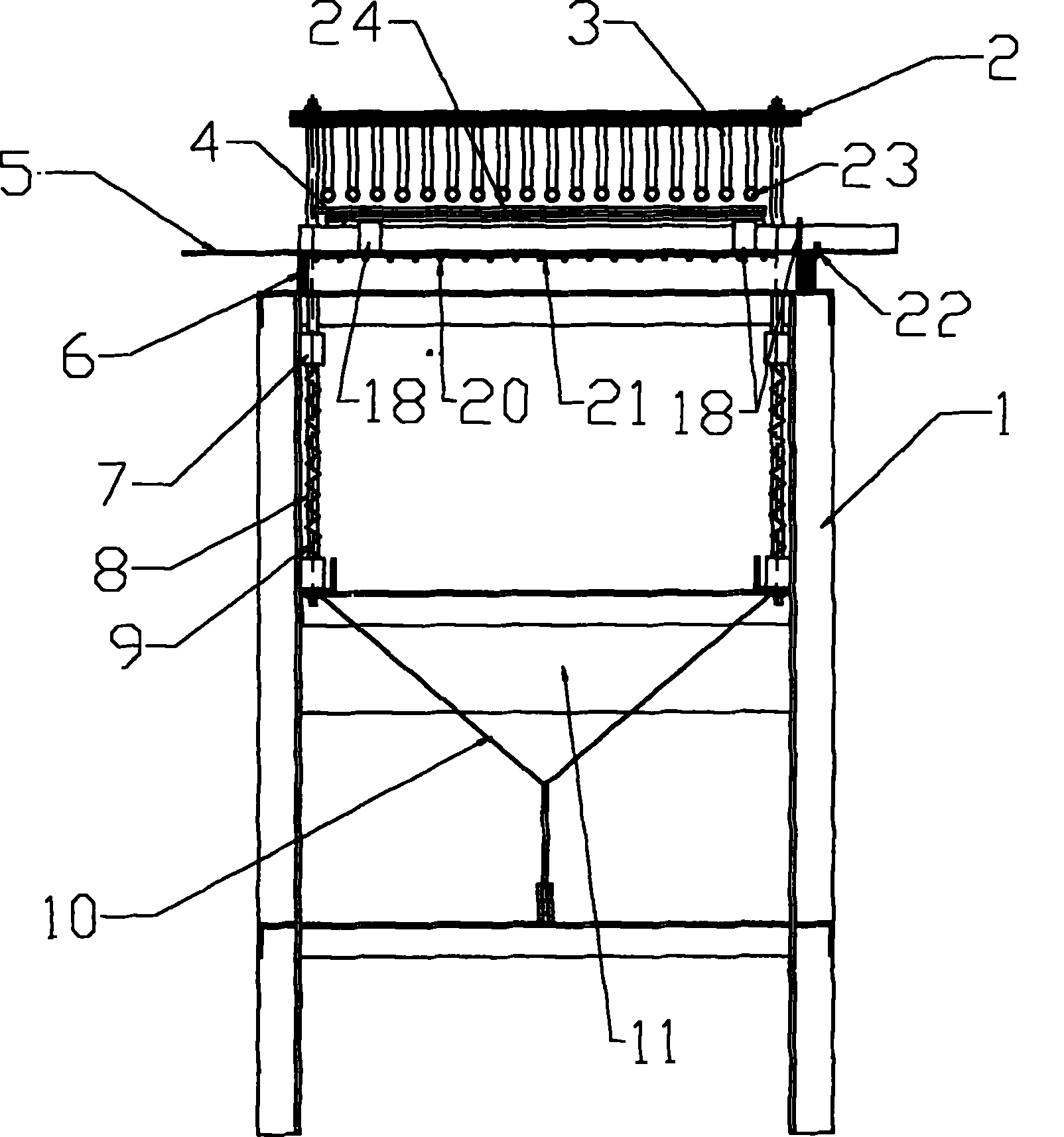

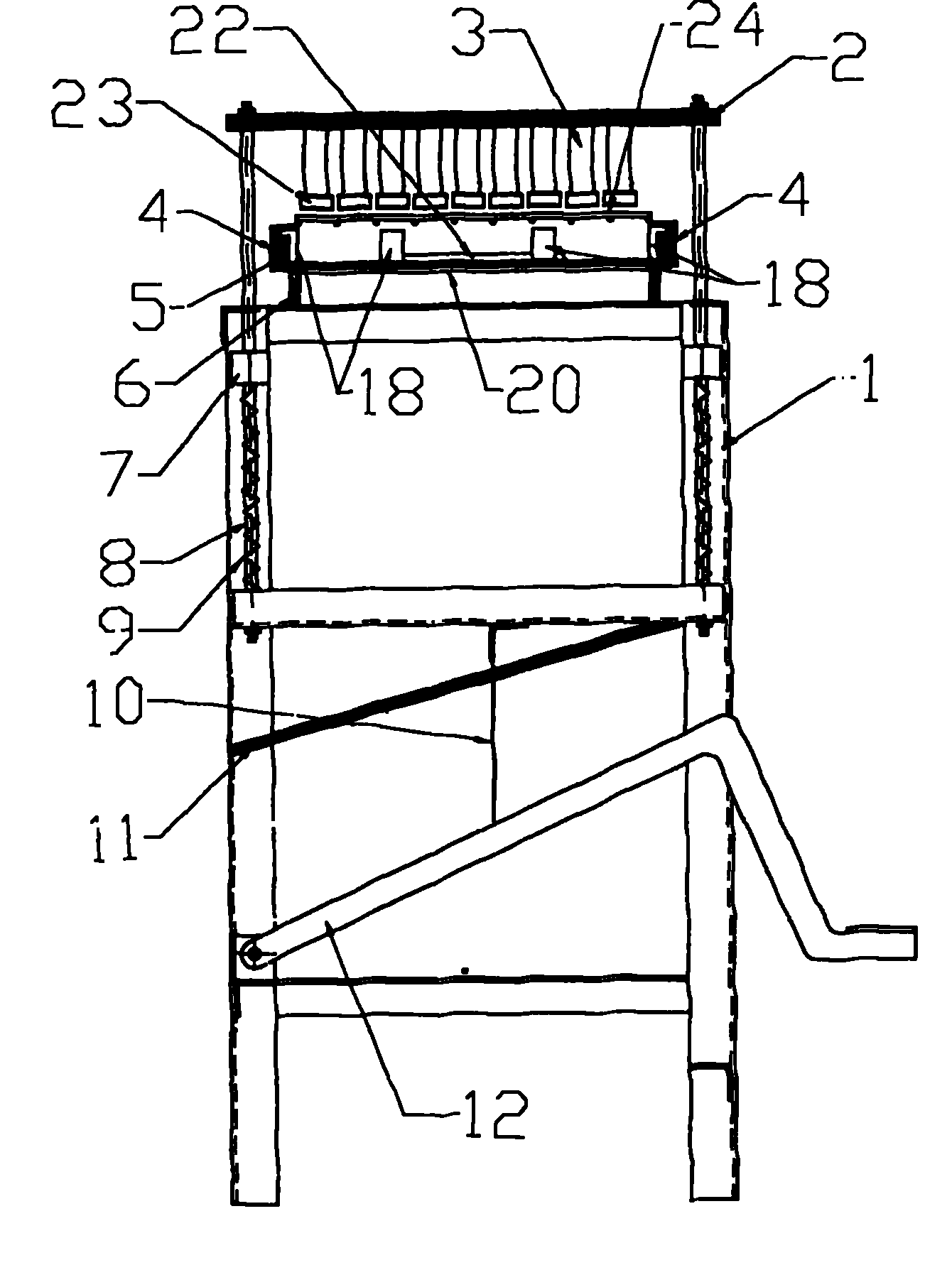

[0023] Embodiment one: if figure 1 , figure 2 As shown, in the cocoon stripping machine, the frame (1) is a frame structure, the cocoon isolating device (6) is installed on the surface frame of the frame (1), and a grid cluster is installed above the cocoon isolating device (6). Shaping positioning frame guide rails (4), grid cluster blocking grids (24) are installed between the grid cluster shaping positioning frame guide rails (4) and push rods (3), respectively installed on the 4 columns of the frame (1) There are 2 linear bearings (7), and the linear bearings (7) of each column are pierced with guide rods (8). The guide rods (8) can reciprocate up and down along the linear bearings (7), and the guide rods (8) The upper end is provided with the push rod plate (2) that is fixed with the push rod (3), and the cocoon connecting plate (11) for accepting silkworm cocoons is installed in the lower middle of the frame (1).

[0024] The power of this embodiment is manpower, the ...

Embodiment 2

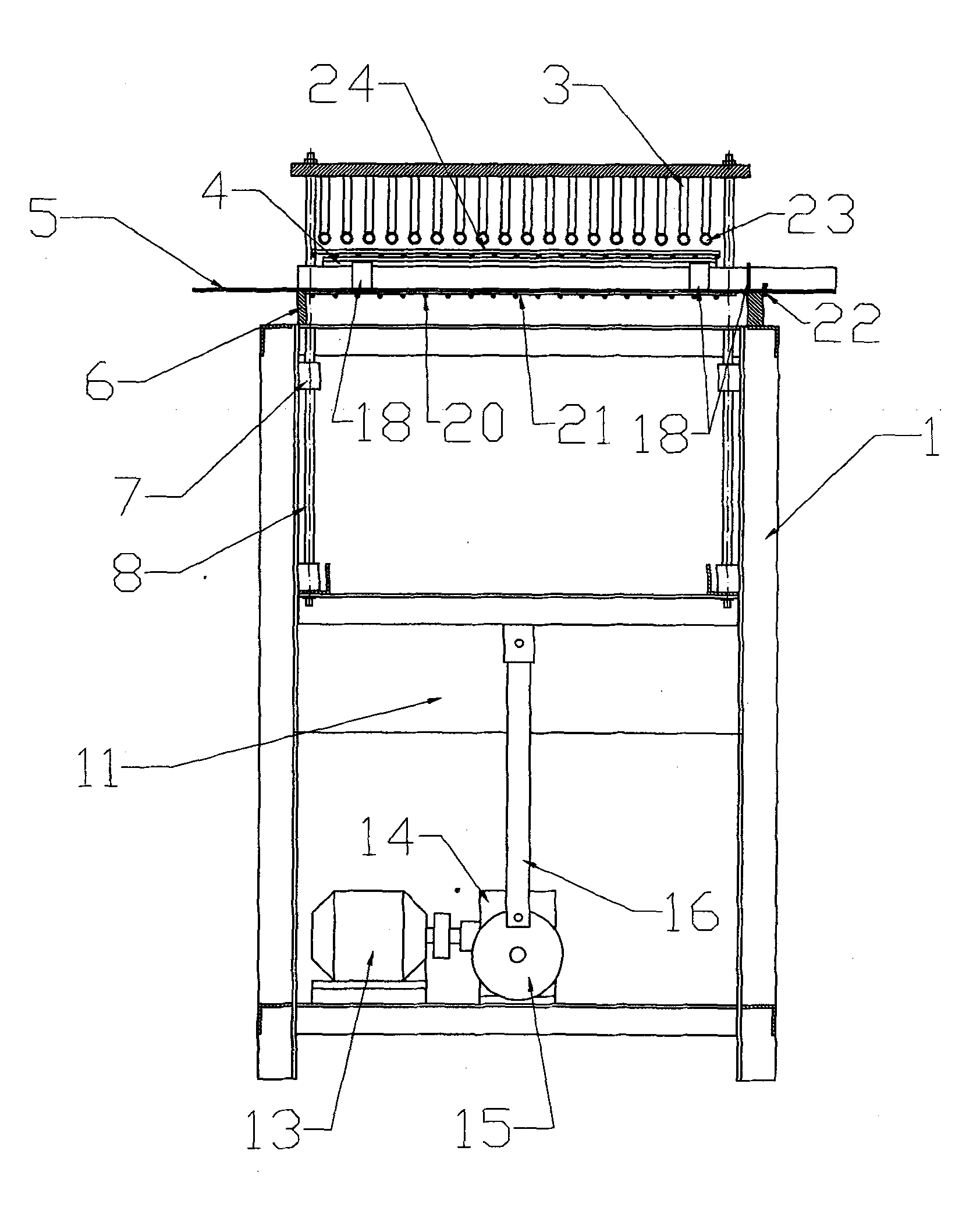

[0029] Embodiment two: if image 3 Shown, power is electric power, and driving device is motor (13), and speed reducer (14), disc (15), connecting rod (16), linear bearing (7), guide rod (8) form reciprocating mechanism. During operation, start the motor to make the reciprocating mechanism move downwards first, and then move upwards. When moving upwards to the top dead center, the touch block touches the limit switch to stop the motor (13). All the other are the same as the first embodiment.

Embodiment 3

[0030] Embodiment three: as Figure 4 As shown, the power is compressed air, the driving device is a double-acting cylinder (17), and the up and down reciprocating movement of the guide rod (8) is realized by the double-acting cylinder (17). Air, the piston rod pulls down the frame connecting the guide rod (8) to make the guide rod (8) move down to the bottom dead center, and then the rodless cavity of the cylinder is sucked in by operating the manual reversing valve, and the piston rod pushes up the connection guide The frame of the rod (8) moves the guide rod (8) upwards to top dead center. All the other are the same as the first embodiment.

[0031]The process of peeling off the cocoon is described below as an example when the power is manpower.

[0032] When the push rod plate (2) is at the top dead center position, the cocoon stripping operation is started, and the grid cluster shaping positioning frame (5) located under the push rod (3) is pulled out along the grid clu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com