Online sterilization device and method for dietary fibers

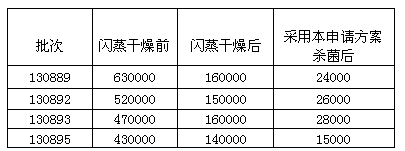

A sterilization device and dietary fiber technology, applied in food preparation, food science, application and other directions, can solve the problems of product flavor change, high microwave sterilization cost, and product water retention function decline, etc., to remove beany smell and reduce the total number of colonies. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

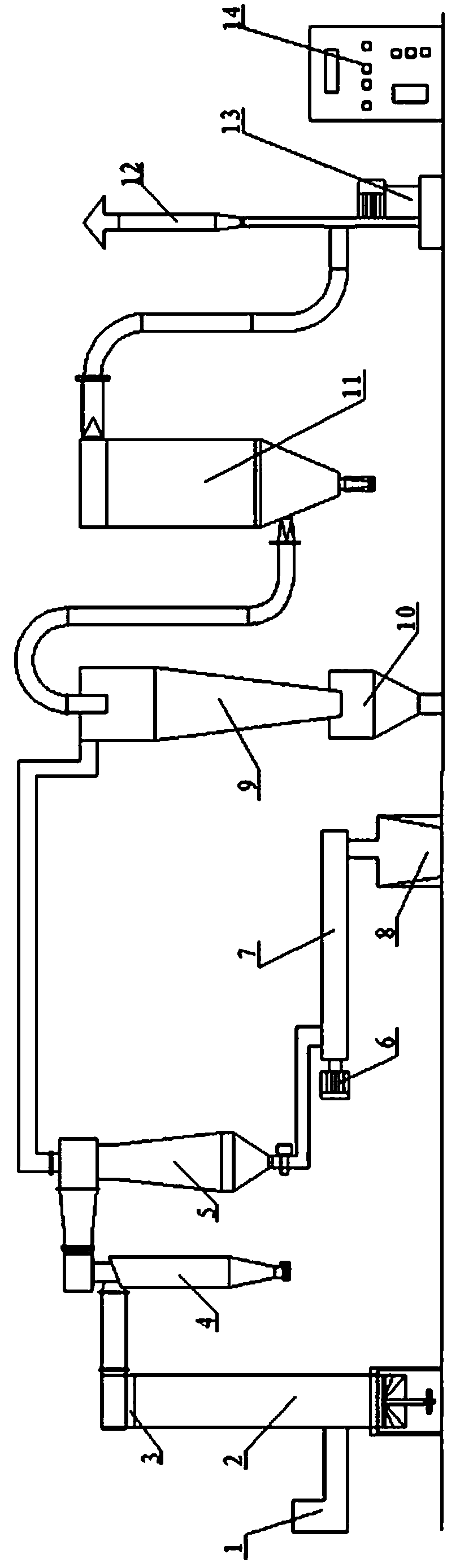

[0024] As shown in the drawings, the dietary fiber on-line sterilization device provided in this embodiment includes a flash dryer, and the flash dryer includes a screw feeder 1, a flash drying host 2, a primary cyclone separator 4, and a secondary cyclone separator. 5, cyclone dust collector 9, bag dust collector 11, induced draft fan 13 and control cabinet 14, the flash drying host 2 is equipped with a heater, condensate recovery system and inlet fan, and the bottom of the secondary cyclone separator 5 is equipped with an outlet feeder, the top of the rotary flash main engine is provided with a classification ring 3, the bottom of the cyclone dust collector 9 is provided with an ash hopper 10, the rear of the bag filter 11 is provided with an exhaust gas pipeline 12, and the secondary cyclone separator 5 is connected with the cyclone dust collector 9 are also provided with a sterilizer 7 and a steam heater. The front and rear parts of the sterilizer 7 cavity are respectively ...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, the difference is:

[0038] The bag dust collector 11 is adopted as a mechanical rotary reverse blowing dust collector.

[0039] During the dietary fiber preparation process, the air inlet temperature of the flash drying host 2 is 140°C, and the steam temperature in the sterilizer 7 is 150°C.

Embodiment 3

[0041] This embodiment is basically the same as Embodiment 2, the difference is:

[0042] During the dietary fiber preparation process, the air inlet temperature of the flash drying host 2 is 170°C, and the steam temperature in the sterilizer 7 is 160°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com