Method for preparing flavor agent I+G (disodium 5'-inosinate + disodium guanylate) released by conditions

An umami agent and conditioned technology, which is applied in the field of preparation of conditioned release umami agent I+G, can solve the problems of I+G phosphomonoesterase hydrolysis and other problems, and achieve the effect of protecting the taste effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

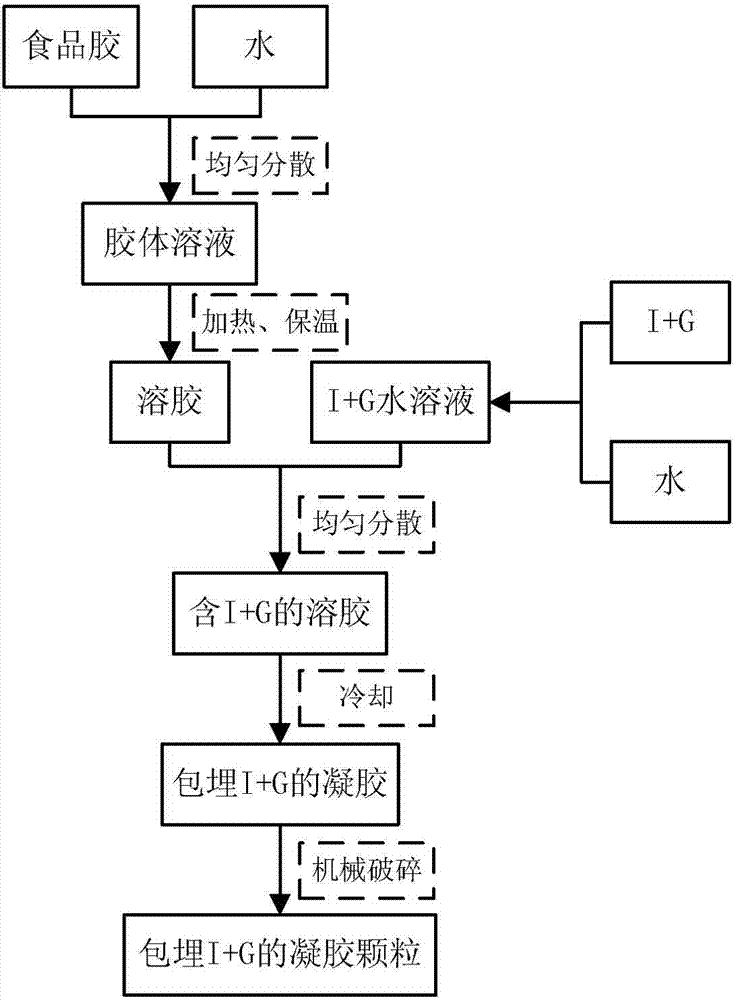

[0017] The invention discloses a method for preparing conditionally released umami flavor agent I+G, the process flow is shown in figure 1 As shown, the specific steps are as follows:

[0018] Step 1: Prepare an aqueous food glue solution with a mass percentage of 0.5%~20%, and stir quickly to make it evenly dispersed; the food glue is a heat-reversible hydrophilic food glue: agar, carrageenan, and sodium alginate;

[0019] Step 2: Heat to boil, stir continuously to fully dissolve the colloid, and control the temperature to 60~95°C to make it in a sol state;

[0020] Step 3: Take the I+G aqueous solution and mix well with the sol;

[0021] Step 4: Cool to gel, and use mechanical means to make gel particles containing I+G with a diameter of 0.1~0.5cm, that is, to make gel particles embedded with I+G;

[0022] Step 5: Add gel particles to the slurry of food products according to the required amount of I+G, disperse evenly, marinate and then shape and ripen.

Embodiment 1

[0024] Taking minced meat products as the application object, the process and processing parameters are as follows:

[0025] Step 1: Prepare 1.5%~2% carrageenan aqueous solution, chop and mix quickly for 5~7min to disperse evenly in water;

[0026] Step 2: Heat and boil for 3-5 minutes until the carrageenan is fully dissolved to form a sol, and keep warm at 65-75°C;

[0027] Step 3: dissolving and preparing an I+G aqueous solution with a mass fraction of 0.1% to 0.15%;

[0028] Step 4: Mix the carrageenan solution with the I+G solution and stir for 2-3 minutes until the mixture is uniform, and control the temperature between 60-65°C;

[0029] Step 5: cooling to gel, making carrageenan gel particles with a diameter of 0.2 to 0.3 cm;

[0030] Step 6: Carrageenan gel particles are added according to the required amount of I+G during the mixing process of the minced meat products.

Embodiment 2

[0032] Taking quick-frozen beef balls as the application object, the process and processing parameters are as follows:

[0033] Step 1: Prepare 10%~15% agar aqueous solution, stir rapidly for 3~5min to fully dissolve the agar;

[0034] Step 2: Heat to 90~95°C to make the agar solution form a sol, and keep it warm at 80~95°C;

[0035] Step 3: Add the I+G aqueous solution in the aqueous state to the agar sol, stir and mix well; and pay attention to control the temperature not lower than 60°C to prevent the agar from gelling.

[0036] Step 4: After cooling to form an agar gel, make gel particles with a diameter of 0.1 to 0.2 cm;

[0037] Step 5: During the preparation of the beef ball slurry, add an appropriate amount of agar gel particles at the mixing process based on the required amount of I+G, and make the beef ball slurry after mixing;

[0038] Step 6: marinate the slurry in a low temperature room of 0-5°C for 6-8 hours, then shape and mature;

[0039] Step 7: After quick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com