Manufacturing method of fish ball production machine capable of remarkably increasing yield

A technology to increase production and manufacturing methods, applied in the field of fish ball making machinery, can solve the problems of fish ball quality specifications and hygiene can not be guaranteed, low production efficiency, slow production speed, etc., to achieve compact structure, high production efficiency, The effect that the manufacturing method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

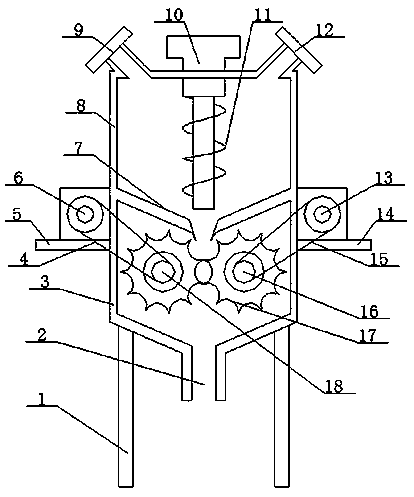

[0022] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention.

[0023] A manufacturing method of a fish ball making machine of the present invention that significantly increases output, wherein, comprises the following steps: A, the pill making bin is respectively welded and fixed with pillars near the lower ends of the two side walls, the pillars are 1.5m in length and 20cm in diameter, Steel column structure, the middle end of the bottom of the pelletizing chamber is equipped with a discharge port, the diameter of the discharge port is 10cm, the lower end of the discharge port is perpendicular to the ground, suspended at the bottom of the pelletizing chamber, and the middle of the inner cavity of the pelletizing chamber is fixed by horizontal welding There are left turntable and right turntable, the diameter of left turntable and right turntable is 50cm, the left tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com