Practical broom head

A broom head and broom technology, applied in the field of cleaning tools, can solve the problems of easy omission of small garbage, unsatisfactory cleaning effect, poor cleaning effect, etc., and achieve the effect of good effect, good elasticity, and reduced number of roots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

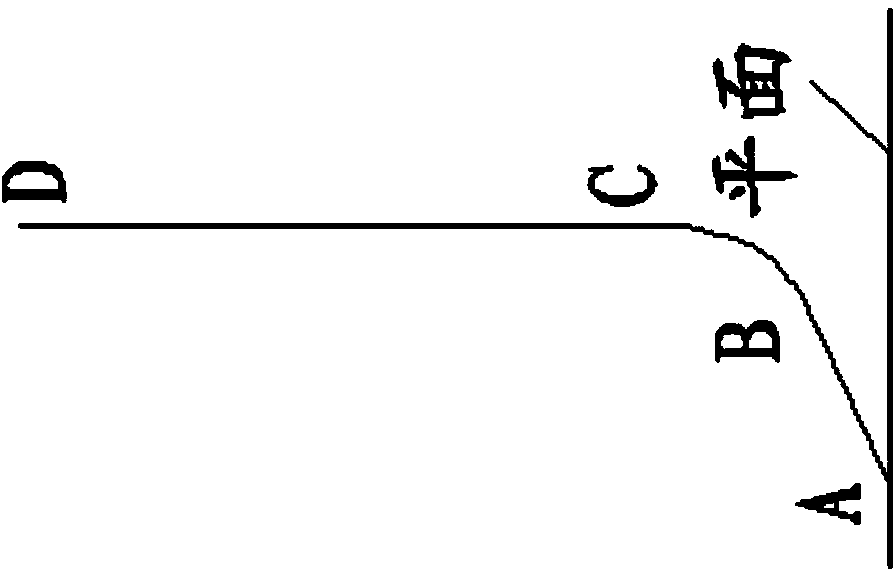

[0033] Such as Figure 2a , Figure 2b As shown in , the broom head 4 includes several broom filaments 1 and a support 3, and one end of the broom filament 1 is fixedly installed on one side of the support 3 in turns.

[0034] exist Figure 2a Among them, the bending direction of each broom filament is parallel to the paper surface, and the bending direction is consistent. When working, the broom head 4 shown in the figure moves perpendicular to the paper surface, Figure 2b shown as Figure 2a The schematic diagram of the left view of , the broom head 4 shown in this figure moves parallel to the paper surface.

[0035] In order to simplify the manufacturing process, the shape and size of each broom filament 1 on the broom head 4 are the same.

[0036] The installation and arrangement of each turn of broom wire 1 on the support 3 adopts the prior art, the turn spacing of each turn of broom wire is generally about 10mm, the diameter of a single broom wire 1 is 0.2mm-0.5mm, ...

Embodiment 2

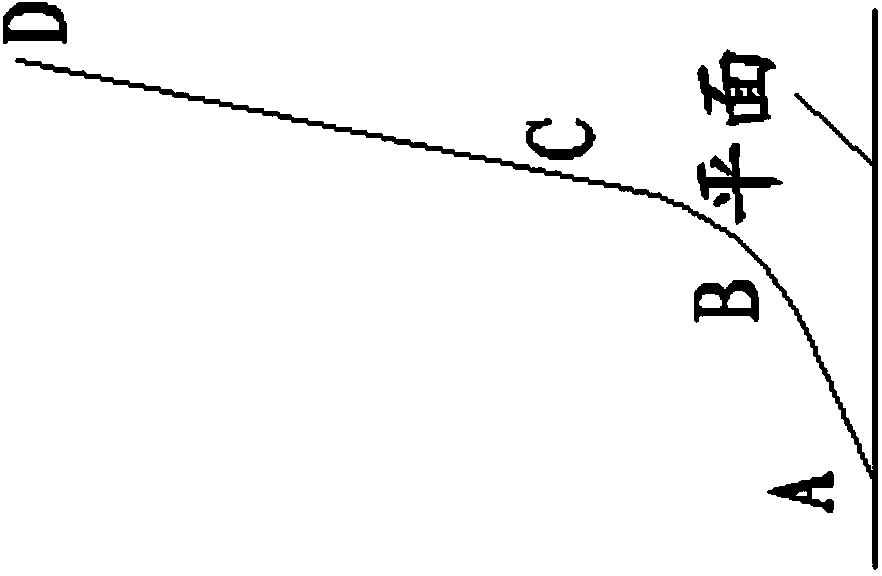

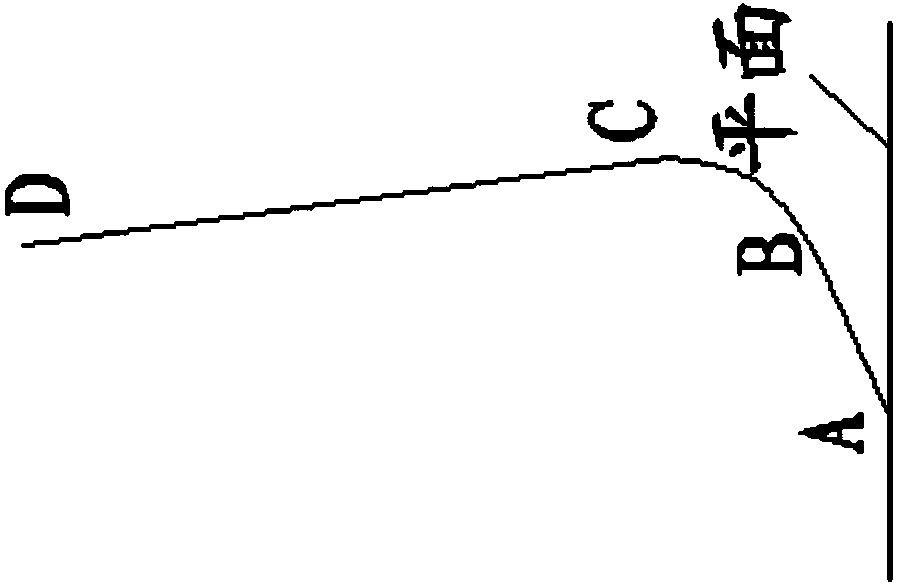

[0041] Such as Figure 3a , 3b Shown, broom head 4 adopts existing tie-up process to make.

[0042] exist Figure 3a Among them, the bending direction of each broom filament is parallel to the paper surface, and the bending direction is consistent. When working, the broom head 4 shown in the figure moves perpendicular to the paper surface, Figure 3b shown as Figure 3a The schematic diagram of the left view of , the broom head 4 shown in this figure moves parallel to the paper surface.

[0043] From Figure 3a It can be seen from the figure that each broom filament 1 is radially arranged parallel to the paper surface, and the CD segments of the broom filaments 1 on the left and right sides of the broom head 4 will have a large inclination. If the BC segments of each broom filament 1 still use If the length and radius of curvature are the same, the inclination angles of the AB sections of the broom filaments 1 will be greatly different, and if they exceed the limit range, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com