Mold suitable for extruding of small-inner-diameter pipe and use method thereof

A small inner diameter, mold technology, applied in the direction of metal extrusion molds, etc., can solve the problems of enterprise loss, low pressure, easy breakage of bosses, etc., and achieve the effects of cost risk reduction, simple use, and avoiding scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

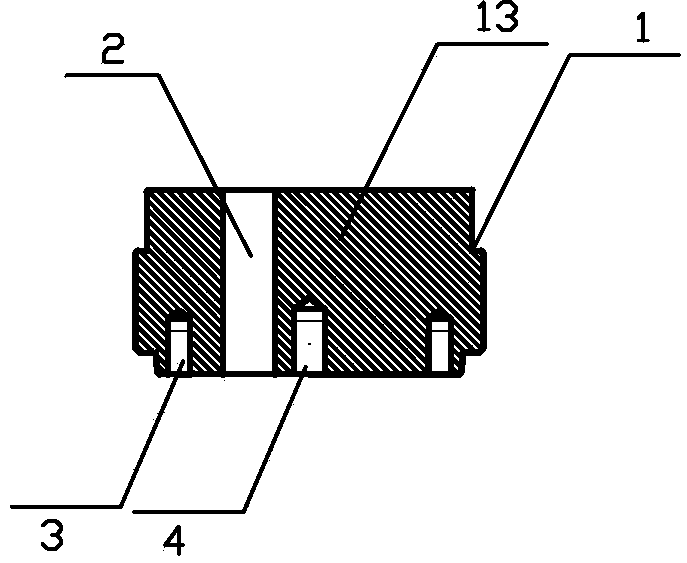

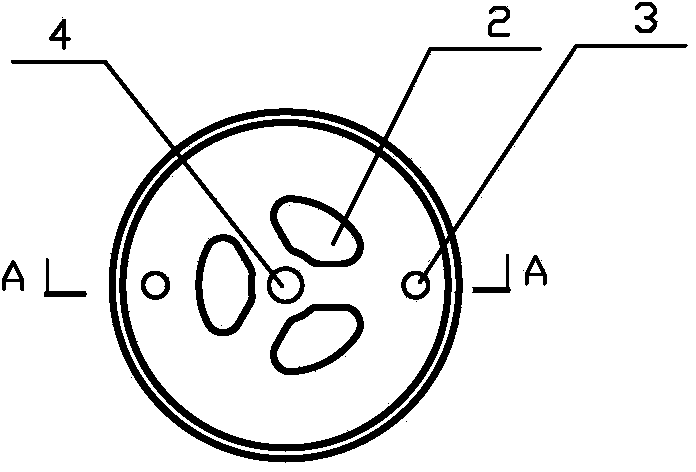

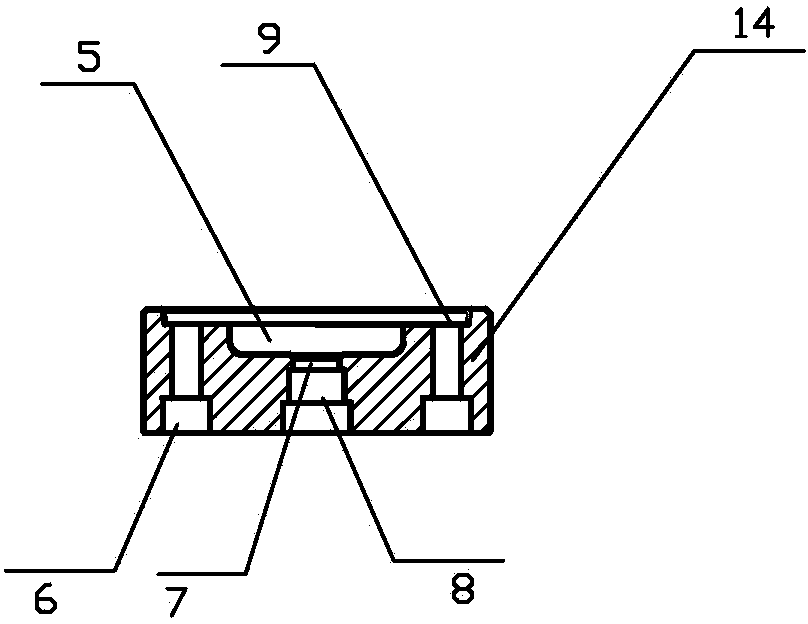

[0028] Such as Figure 1-5 , the mold for extruding a pipe with a small inner diameter described in this embodiment includes an upper mold and a lower mold, the upper mold includes an upper mold body 13, and the lower mold includes a lower mold body 14, and it is characterized in that the upper part of the upper mold body 13 is The first fastening screw hole 3 is set on the bottom and the bottom, the boss installation screw hole 4 is set in the middle, the feed inlet 2 is set around the boss installation screw hole 4, the outer rear end of the upper mold body 13 is provided with a tail stop 1; the lower mold body 10 Set the second fastening screw hole 6 corresponding to the first fastening screw hole 3, set the discharge port 8 in the middle, set the working belt 7 at the upper end of the material discharge port 8, set the welding chamber 5 at the upper end of the working belt 7, and the lower die body 10 Groove 9 is set on the top.

[0029] When the upper mold and the lower ...

Embodiment 2

[0042] The mold for extruding a pipe with a small inner diameter described in this embodiment includes an upper mold and a lower mold, the upper mold includes an upper mold body 13, and the lower mold includes a lower mold body 14, and it is characterized in that the upper and lower mold bodies inside the upper mold body 13 The first fastening screw holes 3 are arranged in the lower part, the boss installation screw holes 4 are arranged in the middle, the feed inlet 2 is arranged around the boss installation screw holes 4, the rear end of the upper mold body 13 is provided with a tail stop 1; the lower mold body 10 Set the second fastening screw hole 6 corresponding to the first fastening screw hole 3, set the discharge port 8 in the middle, set the working belt 7 at the upper end of the discharge port 8, set the welding chamber 5 at the upper end of the working belt 7, and set the top of the lower mold body 10 Set groove 9.

[0043] When the upper mold and the lower mold are ...

Embodiment 3

[0056] The mold for extruding a pipe with a small inner diameter described in this embodiment includes an upper mold and a lower mold, the upper mold includes an upper mold body 13, and the lower mold includes a lower mold body 14, and it is characterized in that the upper and lower mold bodies inside the upper mold body 13 The first fastening screw holes 3 are arranged in the lower part, the boss installation screw holes 4 are arranged in the middle, the feed inlet 2 is arranged around the boss installation screw holes 4, the rear end of the upper mold body 13 is provided with a tail stop 1; the lower mold body 10 Set the second fastening screw hole 6 corresponding to the first fastening screw hole 3, set the discharge port 8 in the middle, set the working belt 7 at the upper end of the discharge port 8, set the welding chamber 5 at the upper end of the working belt 7, and set the top of the lower mold body 10 Set groove 9.

[0057] When the upper mold and the lower mold are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com