Large component roll-roll shipment method

A large-scale component, ro-ro technology, which is applied in the field of shipping cargo, can solve the problems of high customization cost, long loading time, and high rental cost of large floating cranes, so that the rental cost can be easily controlled and the shipping cost can be controlled. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

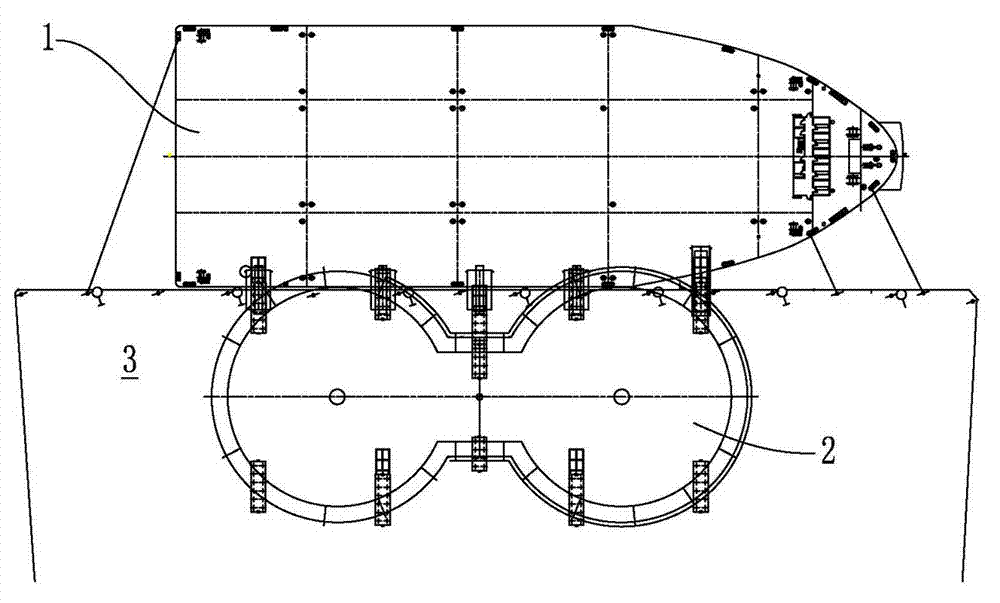

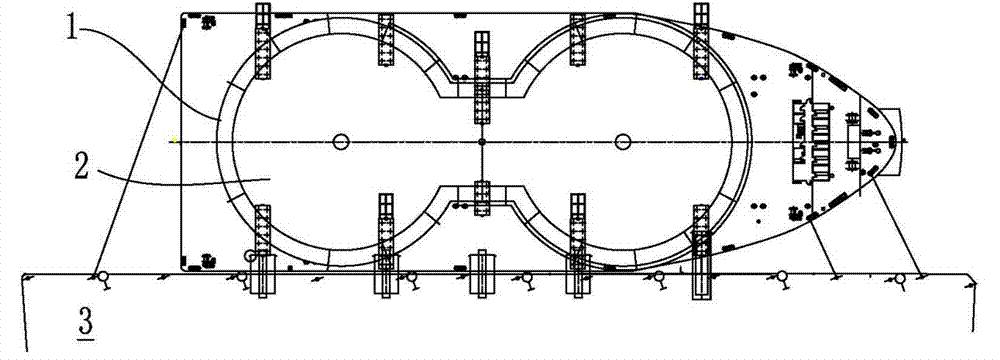

[0029] The large-scale member roll-on-roll-on-shipping method of the present invention is now described in conjunction with the accompanying drawings. The method mainly includes a loading preparation stage and a lateral roll-on-rolling stage. The specific steps are as follows:

[0030] Shipment preparation stage (such as figure 1 shown)

[0031] A, one side of the ship's 1 hull (that is, the side of the ship) is docked in place along the wharf 3, wherein figure 1 with figure 2 In the schematic diagram, the shipping ship 1 is a barge, and the barge is towed by a tugboat;

[0032] B. Place buttresses on the deck of the shipping vessel according to the condition of the shipping member itself;

[0033] C. According to the operating range of the SPMT self-propelled flatbed truck, lay steel plates between the side of the ship's hull and the edge of the wharf;

[0034] D. Use three rows of SPMT self-propelled flatbed trucks arranged forward and backward along the width direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com