Low-cost halogen-free chemical flame-retardant vinyl ester resin and preparation method thereof

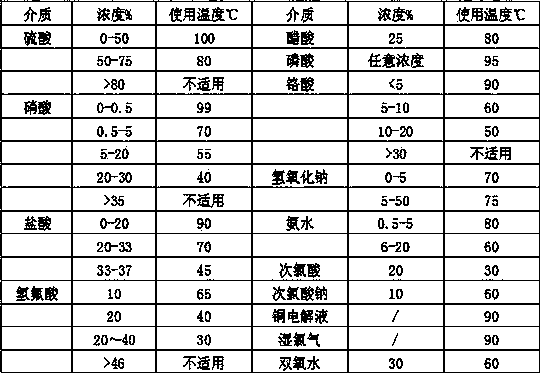

A vinyl ester resin and flame-retardant technology, which is applied in the field of low-cost halogen-free chemical flame-retardant vinyl ester resin and its preparation, can solve the problems of unstable flame-retardant effect, poor flame-retardant effect, and high cost. Achieve obvious flame retardant effect, more stable flame retardant effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

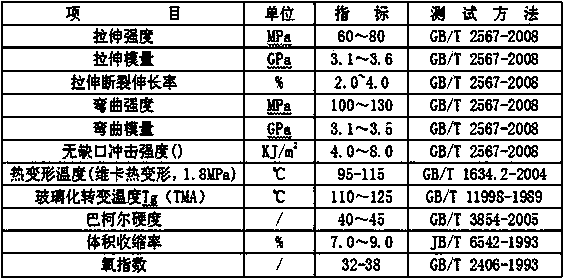

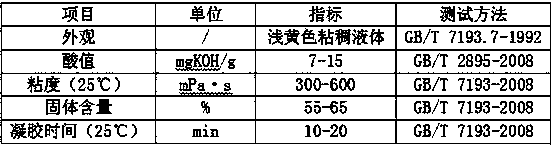

[0036] Put 200g of bisphenol A type E-51 epoxy resin into the reaction kettle with a thermometer, agitator, and gas conduit condenser, stir and gradually raise the temperature to 75°C, add 80g of methacrylic acid, benzyl trimethyl chloride Ammonium chloride 0.8g and hydroquinone 0.05g, benzyltrimethylammonium chloride and hydroquinone were dissolved in methacrylic acid and added, stirred and gradually heated up, kept at 120°C for 1.5h, and the measured acid value dropped to 4mgKOH / g, cool down to 110°C, then add 25g of phosphoric acid dropwise according to the metering ratio, finish the dropwise addition within 30min, then raise the temperature to 120°C, keep the temperature until the acid value drops to 15mgKOH / g, cool down to below 100°C Add 150 g of styrene and 0.05 g of methyl hydroquinone, stir well, cool and filter to obtain a light yellow viscous liquid which is resin sample A.

[0037] Wherein, in the above-mentioned examples, bisphenol A type E-51 epoxy resin is repla...

Embodiment 2

[0039] Put 220g of bisphenol A type E-44 epoxy resin into the reaction kettle with thermometer, stirrer, and gas conduit condenser, stir and gradually raise the temperature to 85°C, add 65g of methacrylic acid and 1.0g of triphenylphosphine and methyl hydroquinone 0.05g, triphenylphosphine and methyl hydroquinone were dissolved in methacrylic acid and added, stirred and gradually raised the temperature, kept at 115°C for 2 hours until the acid value dropped below 5mgKOH / g, Cool down to 110°C, then add 50g of phosphoric acid dropwise according to the metering ratio, finish the dropwise addition within 30 minutes, then raise the temperature to 125°C, keep the temperature until the acid value drops to 13mgKOH / g, cool down to below 100°C and add 150g of styrene and 0.05 g of 2,6-di-tert-butylcatechol, fully stirred, cooled and filtered to obtain a light yellow viscous liquid as resin sample B.

Embodiment 3

[0041] Put 200g of bisphenol A type E-51 epoxy resin into the reaction kettle with thermometer, stirrer, and gas conduit condenser, stir and gradually raise the temperature to 80°C, add methacrylic acid 65g, benzyldimethylamine 1.0 g and 0.05g of 2,6-di-tert-butylcatechol, benzyldimethylamine and 2,6-di-tert-butylcatechol were dissolved in methacrylic acid and added, stirred and gradually heated up, and kept at 113°C for 3h, Until the acid value drops to 4.5mgKOH / g, then add 30g of phosphoric acid dropwise according to the metering ratio, and finish the dropwise addition within 30 minutes. Add 150g of chlorostyrene, 0.05g of copper naphthenate and 0.05g of methyl hydroquinone, stir fully, cool and filter to obtain a light yellow viscous liquid which is resin sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com