Ultraviolet light curing anti-fouling paint and preparation method thereof

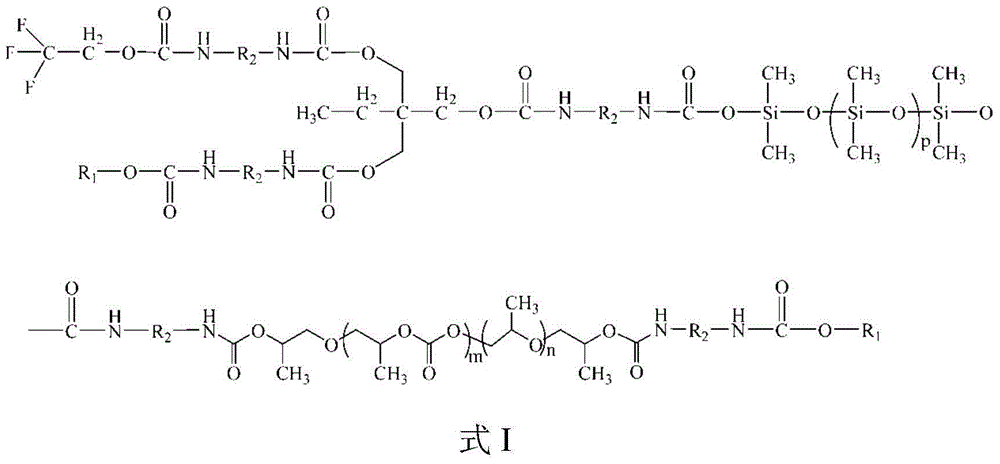

A technology of ultraviolet light and coatings, applied in the direction of antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high cost, poor antifouling effect, poor antifouling durability, etc., and achieve durable antifouling Long-term resistance, improved mold resistance, and excellent compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation method of ultraviolet curing antifouling paint of the present invention comprises the following steps:

[0070] (1) Add multifunctional fluorine-containing silicon urethane acrylate, multifunctional urethane acrylate, leveling agent, and defoamer into a high-speed mixer, and stir at 800-1300rpm for 1-3h, preferably 900-1200rpm for 1.5-2h , to get a mixture;

[0071] (2) Add the mixture, photoinitiator and multifunctional acrylate diluent into a high-speed mixer, and stir at 1100-1500rpm for 10-45min, preferably at 1200-1400rpm for 25-35min, to obtain a UV-curable antifouling coating.

Embodiment 1

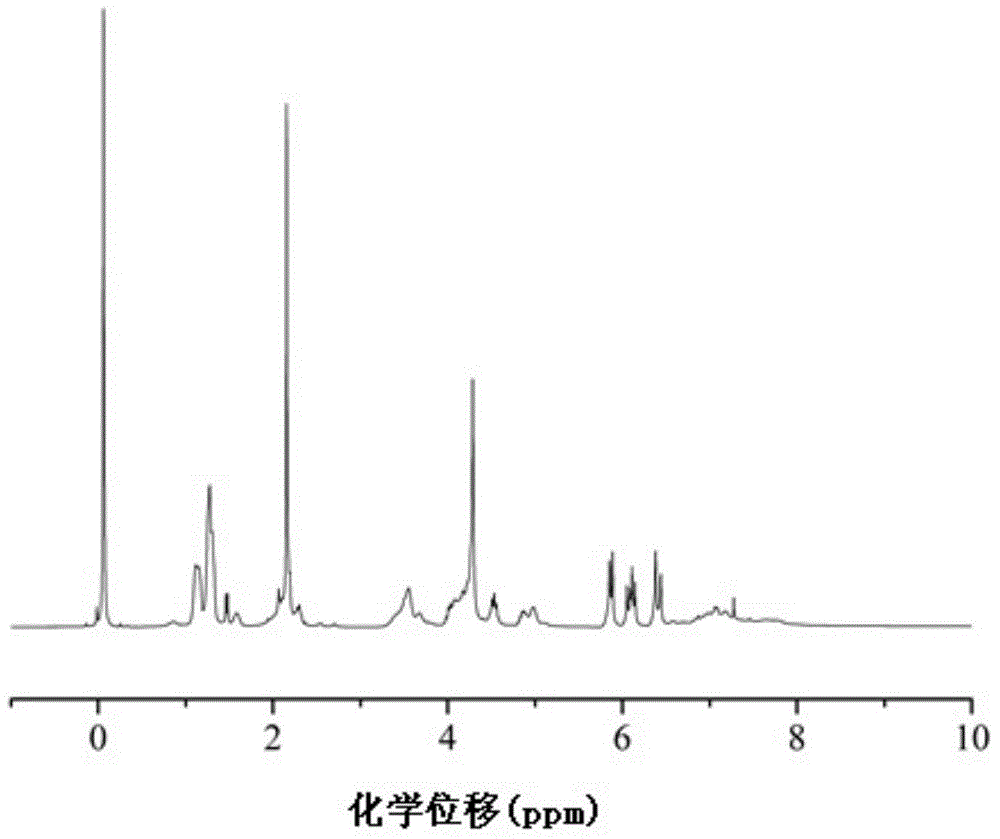

[0074] to combine figure 1 Illustrative Example 1

[0075] Preparation method of polyfunctional fluorine-containing silicon polyurethane acrylate:

[0076] (1) Add 150g of low molecular weight poly(carbonate-ether) glycol (molecular weight 1500 Daltons) into the three-necked flask, heat to 110°C, dehydrate at -0.98MPa for 1h, cool down to 75°C, under nitrogen protection, Add 12.4g of trimethylolpropane, add 87g of 2,4-toluene diisocyanate dropwise at a rate of 5ml / min, after the dropwise addition, react for 2.5h to obtain the first intermediate;

[0077] (2) The temperature is lowered to 70°C, and 0.09g of dibutyltin dilaurate and 8g of hydroxyl polydimethylsiloxane (molecular weight 1000 Daltons) are added dropwise to the first intermediate. After the addition is completed, react for 0.5h , to obtain the second intermediate;

[0078] (3) Add 12.6g trifluoroethanol to the second intermediate, heat up to 80°C, and react for 2h; Then, add 0.57g p-hydroxyanisole, add 113g pent...

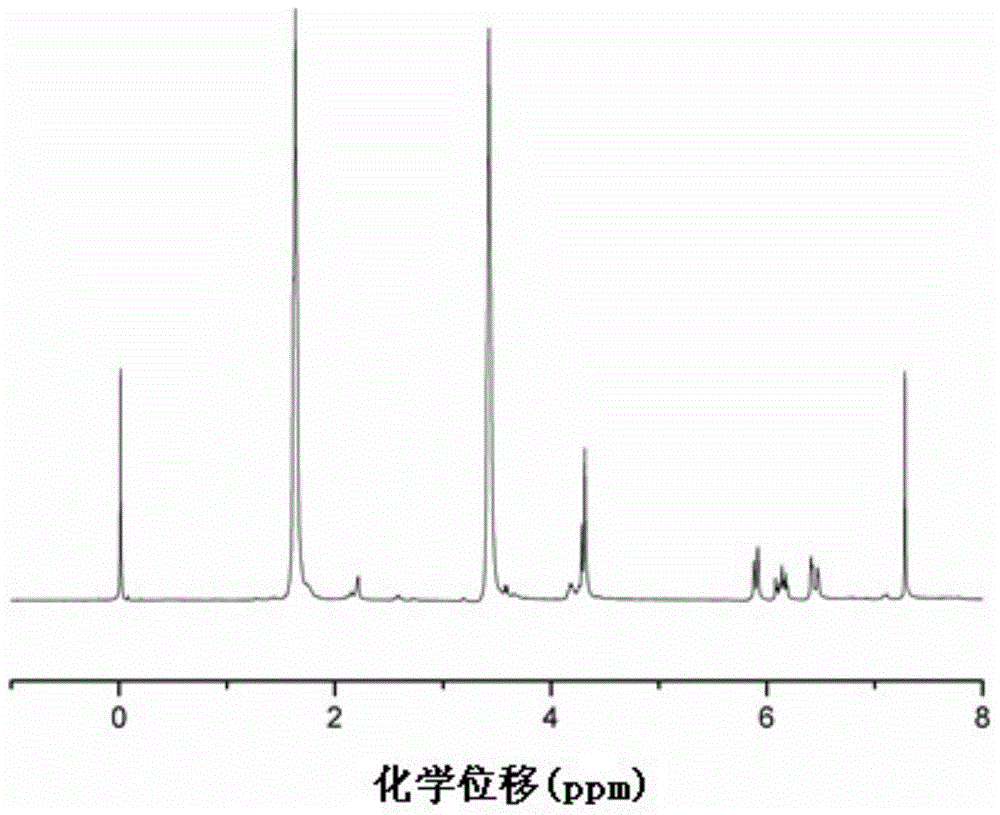

Embodiment 2

[0081] Preparation method of polyfunctional fluorine-containing silicon polyurethane acrylate:

[0082] (1) Add 700g of low-molecular-weight poly(carbonate-ether) glycol (molecular weight: 7000 Daltons) into a three-necked flask, heat to 120°C, dehydrate at -0.98MPa for 3h, cool down to 80°C, under nitrogen protection , add 14.5g trimethylolpropane, add 158g diphenylmethane-4,4-diisocyanate dropwise at a rate of 12ml / min, after the dropwise addition, react for 4h to obtain the first intermediate;

[0083] (2) The temperature is lowered to 75°C, and 0.47g of stannous octoate and 17g of hydroxyl polydimethylsiloxane (molecular weight 4000 Daltons) are added dropwise to the first intermediate. After the addition is completed, react for 2 hours to obtain the first intermediate two intermediates;

[0084] (3) Add 18.7g trifluoroethanol to the second intermediate, heat up to 85°C, and react for 3h; then, add 0.82g hydroquinone, add 235g dipentaerythritol pentaacrylate dropwise at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com