Dewaxing production equipment

A production equipment and dewaxing technology, applied in the direction of petroleum wax recovery, etc., can solve the problems of high investment and operating costs, and achieve the effect of preventing equipment accidents, high safety and good crystallization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

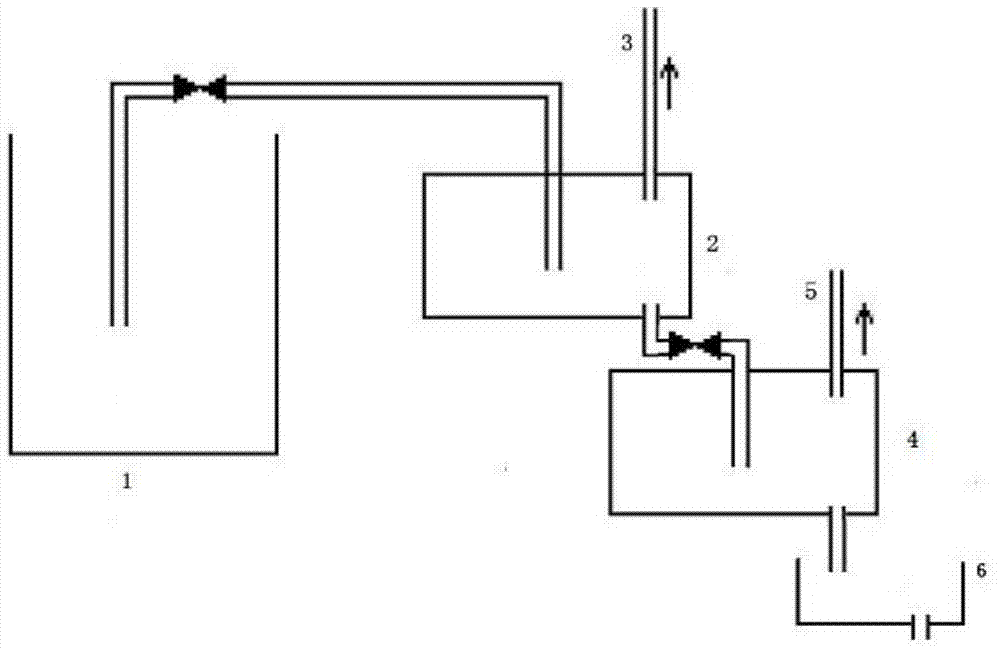

[0019] The dewaxing production equipment includes a raw material tank 1 , a first crystallization tank 2 , a second crystallization tank 4 and a filter 6 which are sequentially connected by pipelines. The first crystallization tank 2 is provided with a first exhaust pipe 3 , and the second crystallization tank 4 is provided with a second exhaust pipe 5 . The filter 6 is covered with adsorbent with a thickness of 300mm. The adsorbent is 4A molecular sieve. The pore diameter of the pipeline of the dewaxing production equipment is Ф18cm. The filter 6 is provided with a backwash pipe, and the backwash pipe is connected with a backwash pump. The aperture of the backwash pipe is Ф15mm.

Embodiment 2

[0021] The dewaxing production equipment includes a raw material tank 1 , a first crystallization tank 2 , a second crystallization tank 4 and a filter 6 which are sequentially connected by pipelines. The first crystallization tank 2 is provided with a first exhaust pipe 3 , and the second crystallization tank 4 is provided with a second exhaust pipe 5 . The filter 6 is covered with adsorbent with a thickness of 200mm. The adsorbent is 4A molecular sieve. The pore diameter of the pipeline of the dewaxing production equipment is Ф10cm. The filter 6 is provided with a backwash pipe, and the backwash pipe is connected with a backwash pump. The aperture of the backwash pipe is Ф12mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com