Leak detector for blast furnace cooler

A technology of coolers and leak detectors, applied in the direction of inspection devices, etc., can solve the problems of no leakage point, hearth freezing, long time, etc., and achieve the effects of shortening detection time, accurate detection, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

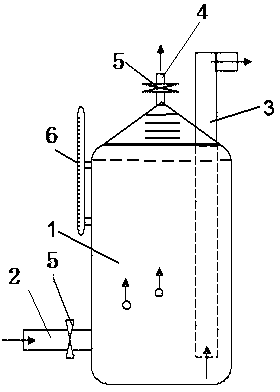

[0011] The present invention will be further described below in conjunction with accompanying drawing, see figure 2 , a blast furnace cooler leak detector, comprising a gas collection tank 1, the gas collection tank 1 is a transparent vessel, a water inlet pipe 2 and a valve 5 are installed below it, and an air outlet pipe 4 and a valve 5 are installed above the gas collection tank 1, Outlet pipe 3 is housed in the gas collection tank 1, and the water outlet of water outlet pipe 3 tops is higher than the air outlet of air outlet pipe 4, and the bottom of water outlet pipe 3 is positioned at the bottom of air collection tank 1.

[0012] A water level gauge 6 is installed on one side of the gas collecting tank 1 .

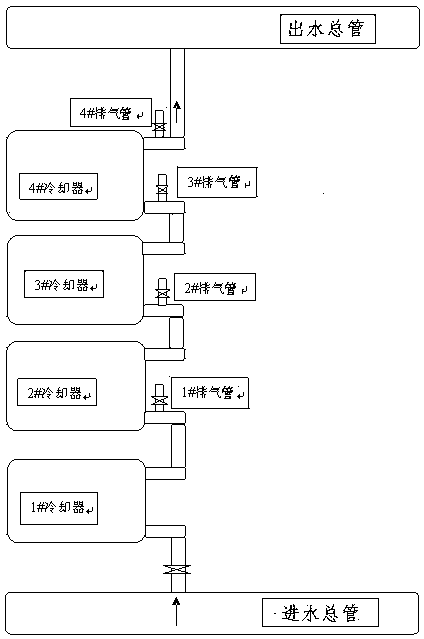

[0013] to combine figure 1 , during normal production of the blast furnace, connect the water inlet pipe 2 of the present invention with a flexible pipe on the exhaust pipe of each cooler, and the water outlet pipe 3 keeps the long-pass state. Open the valve on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com