Novel double-beam rapier loom

A rapier loom, double warp beam technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of complex structure, low tension, few warp interlacing points, etc., to avoid unstable left and right centers of gravity and simple structure Reasonable, good cloth quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

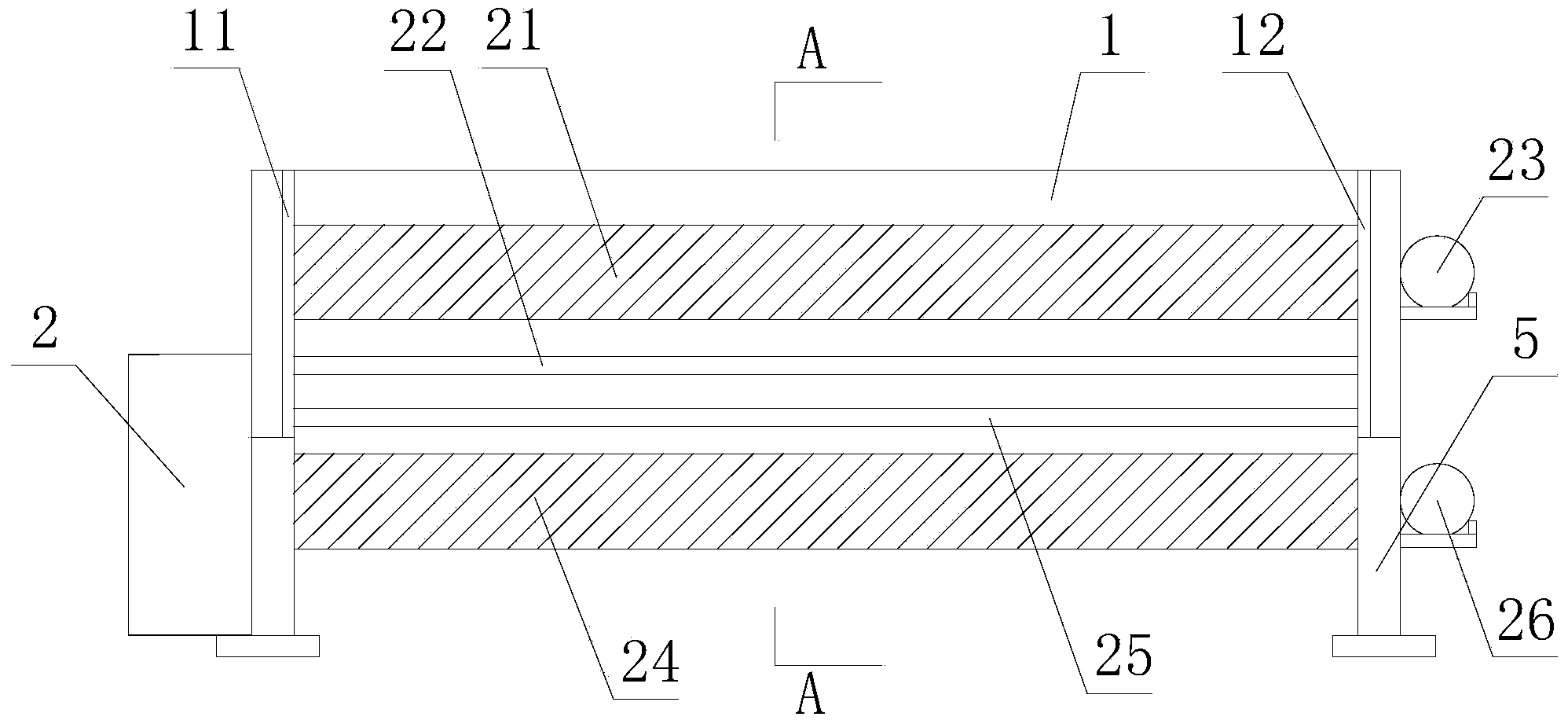

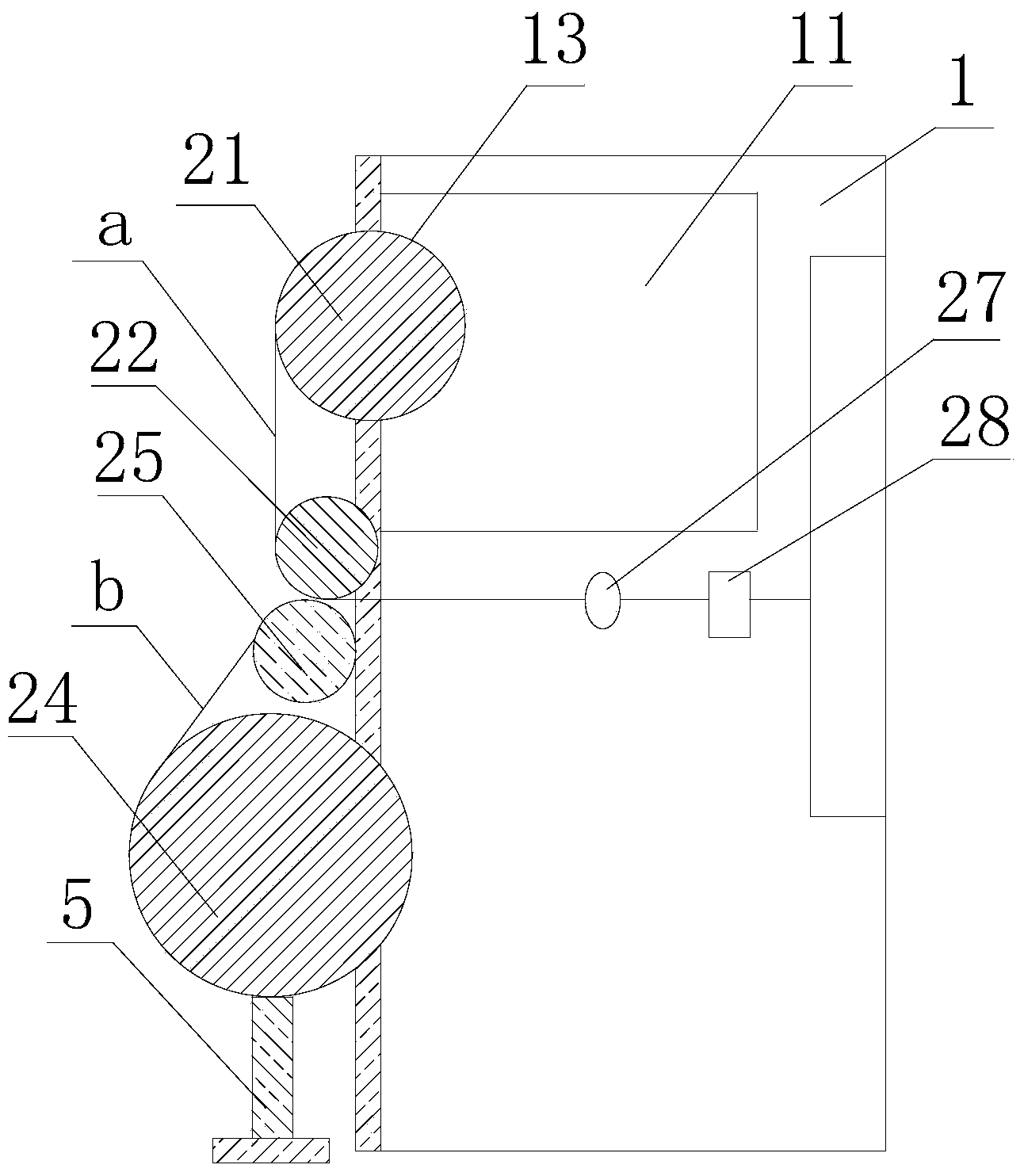

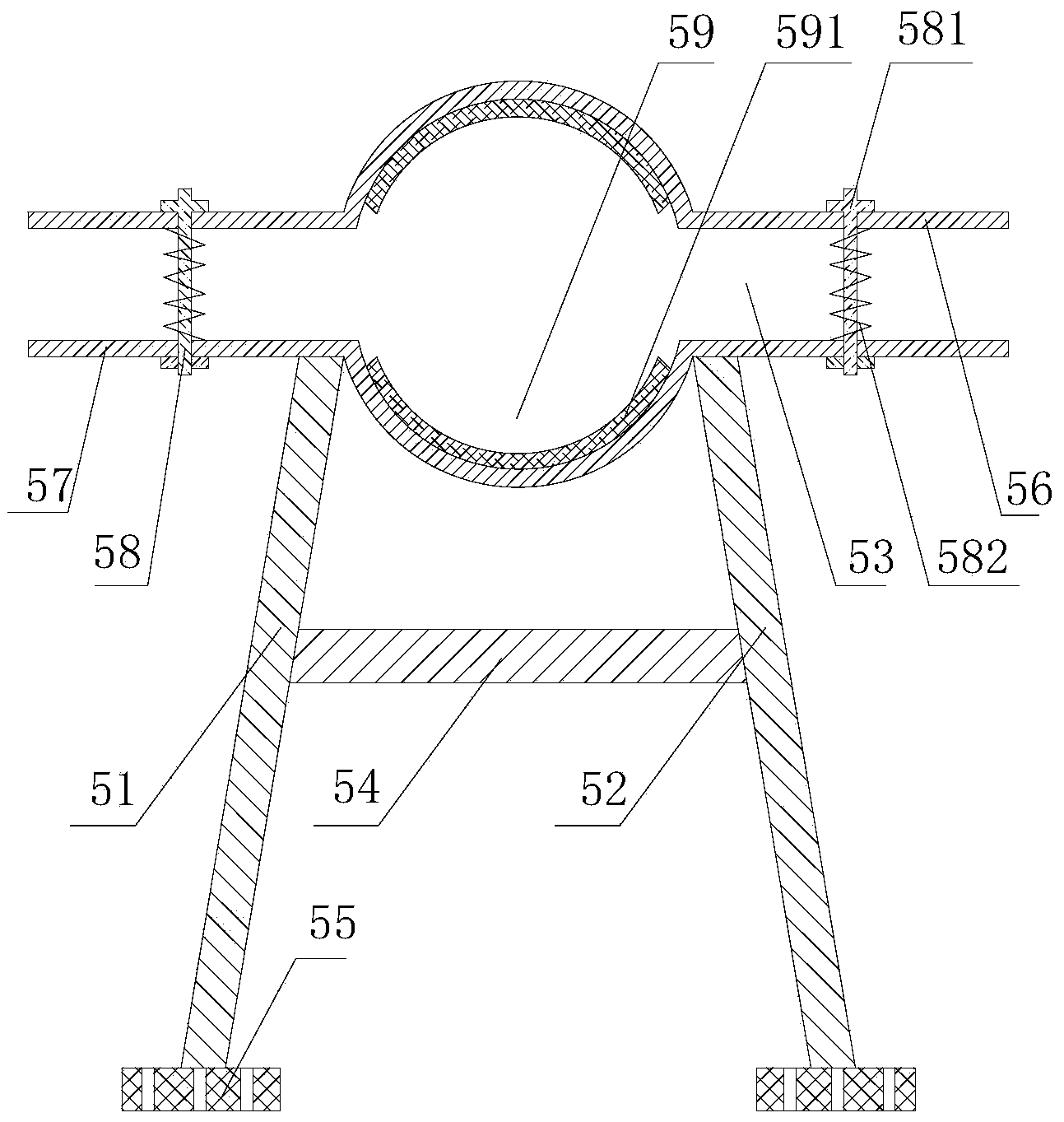

[0023] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present invention comprises frame 1, warp let-off mechanism, beating-up mechanism, drive system 2, winding mechanism, left wall board 11 and right wall board 12 are arranged on described frame 1, and described warp let-off mechanism is fixed on Between the left wallboard 11 and the right wallboard 12, the warp beam seat 13 is all arranged on the left wallboard 11 and the right wallboard 12, and the rear of the let-off mechanism is provided with a heald frame mechanism, and the thickness of the left wallboard 11 is greater than The thickness of the right wallboard 12, the described warp let-off mechanism comprises a first warp let-off assembly and a second warp let-off assembly, and the first warp let-off assembly consists of a first warp let-off shaft 21, an upper rear beam 22 and an upper drive motor 23 Composition, the second warp let-off assembly is made up of the second warp le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com