Construction method of long-span concrete-filled steel tube concrete arch bridge first turned vertically and then hoisted in situ

A concrete-filled steel tube and overall lifting technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of single construction process method, and achieve the effect of reducing risks, improving assembly, and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

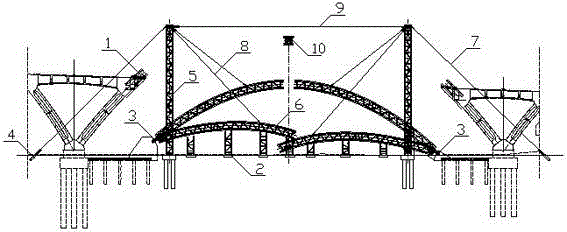

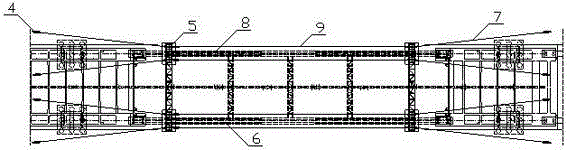

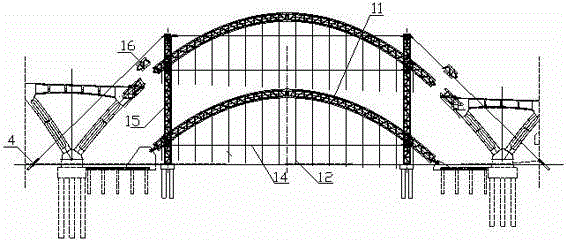

[0032] Such as figure 1 As shown, a long-span concrete-filled steel tube arch bridge is first vertically rotated and then in-situ integrally lifted. The construction method includes the following construction steps:

[0033] 1. Assembly construction

[0034] Complete the main structure of the pier body at both ends of the arch bridge and set up a pre-embedded section 1 of the arch foot on both sides of the main structure of each pier body; corresponding to the pre-embedded section 1 of each arch foot, complete the temporary hinge 3 and the rear anchor point respectively The construction of 4 and the erection and installation of temporary assembly brackets 2 and two hoisting towers 5 as a group, the top of each group of hoisting towers 5 is arranged with lifting cylinders, hoisting cables 15 and bottom anchors; Steel pipe arch ribs are installed by section welding, and cross braces 13 are respectively installed between two mutually parallel arch ribs as a whole to form two swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com