Phase change heat storage type ground heat exchanger

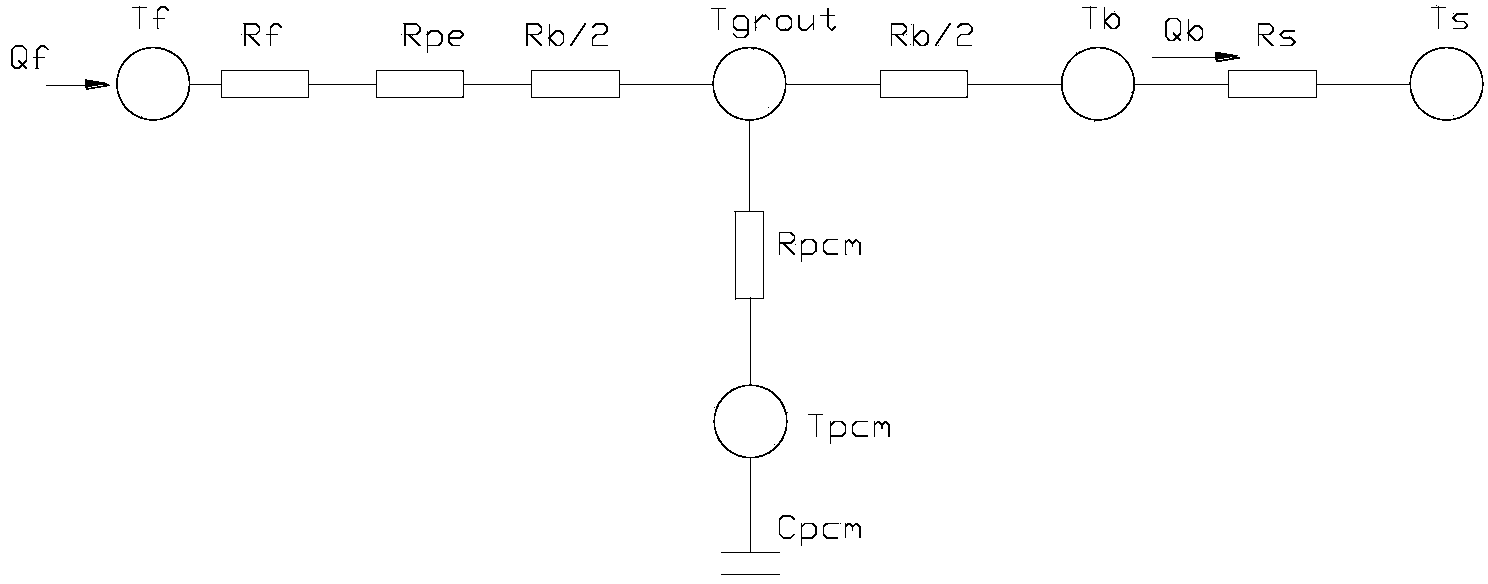

A buried tube heat exchanger and phase change heat storage technology, which is applied in heat pumps, heating methods, heating devices, etc., can solve the problem of not considering the heat storage capacity in the well and the thermal performance of the heat exchanger without considering the heat storage performance, etc. problems, to achieve the effect of reducing the number of buried pipes, reducing construction costs, and reducing the length of buried pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

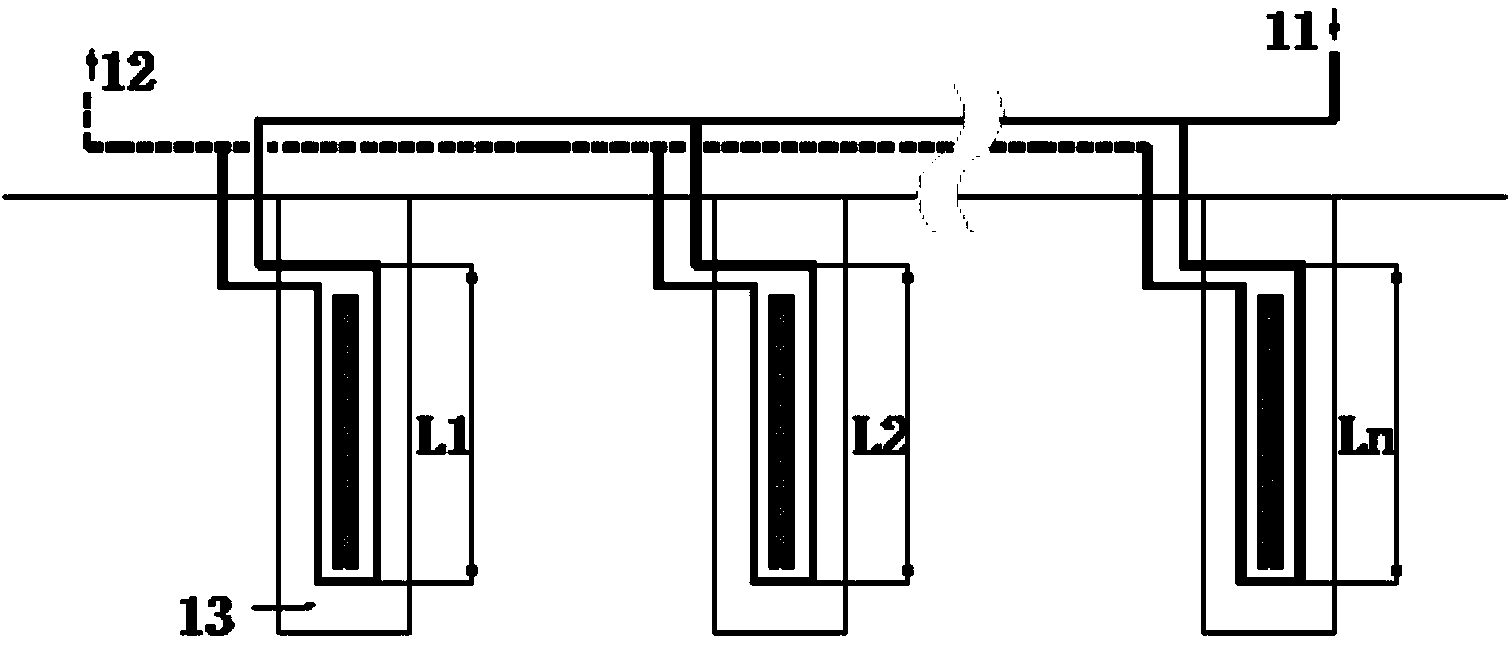

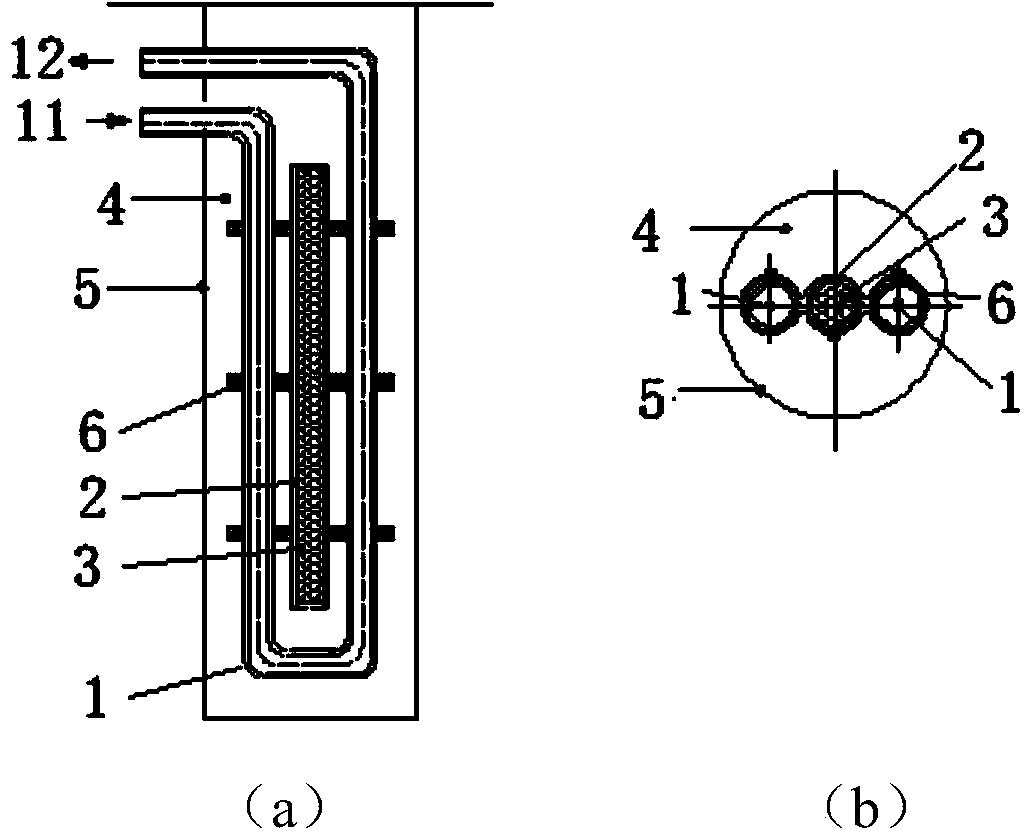

[0033] Implementation 1: The present invention is applied in a single U-circulation vertical buried tube heat exchanger, and phase-change heat storage tubes are arranged according to the heat storage requirements and the space in the well. According to the number of pipes, there are three phase change tube arrangements: single U cycle single tube phase change heat storage, single U cycle double tube phase change heat storage, single U cycle three tube single phase change heat storage. See Figure 4 .

Embodiment 2

[0034] Implementation 2: The present invention is applied in the double U circulation vertical buried tube heat exchanger, and the diameter of the phase change heat storage tube is determined according to the heat storage requirement and the space in the well. The number of pipes is one, which is arranged in the center of the well, that is, double U cycle single pipe phase change heat storage. See Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com