Air pressure sensor testing method and testing system for brake system

A technology of air pressure sensor and braking system, which is applied in the direction of instruments, measuring devices, and measuring fluid pressure, etc. It can solve the problems that the test is not simple, convenient and efficient, and the test and calibration of the air pressure sensor is not intuitive and accurate enough, so as to achieve intuitive testing , test reliability, great social significance and the effects of marketing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

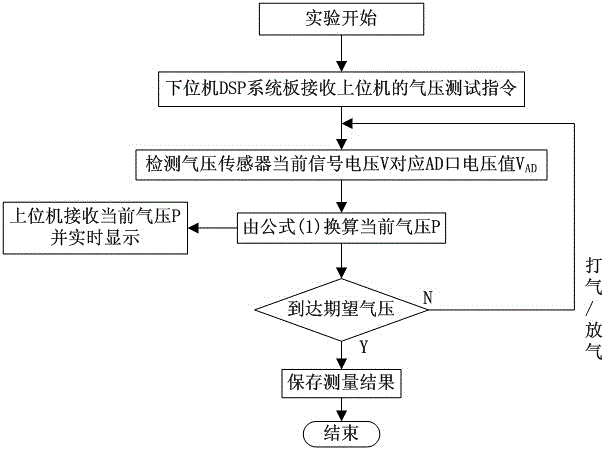

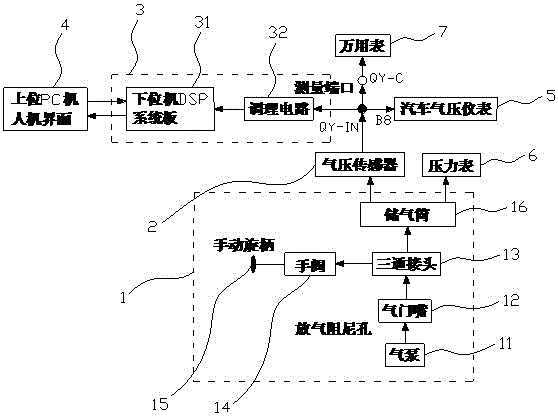

[0024] The air pressure sensor testing method of the braking system of the present invention first calibrates the air pressure sensor to obtain the calibration relationship between the current air pressure P and the current sensor signal voltage V corresponding to the voltage value VAD of the AD port, and then performs the test according to the operator's desired air pressure. Inflate or deflate. During the inflate / deflate process, observe the current air pressure through the pressure gauge, car air pressure gauge and host computer virtual air pressure gauge. When the desired air pressure is reached, measure and save the measurement results.

[0025] The calibration process of the air pressure sensor in the air pressure sensor testing method of the braking system of the present invention is as follows:

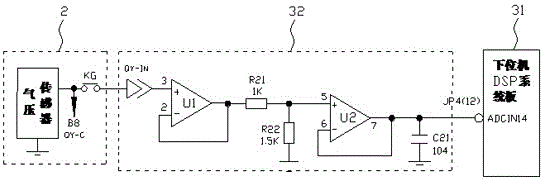

[0026] Such as Figure 4 , 5 As shown, first connect the air pressure sensor signal as a resistance related to air pressure to the terminal B8 of the automobile air pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com