PS copper converter converting process intelligent decision and terminal forecast method and device

A converter blowing and intelligent decision-making technology, which is applied in the intelligent control of copper matte blowing process, intelligent decision-making and end point forecast of PS copper converter blowing process, can solve the problem of increasing low-altitude pollution, large fluctuations in end point judgment errors, and difficulty in timely Accurately grasp issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

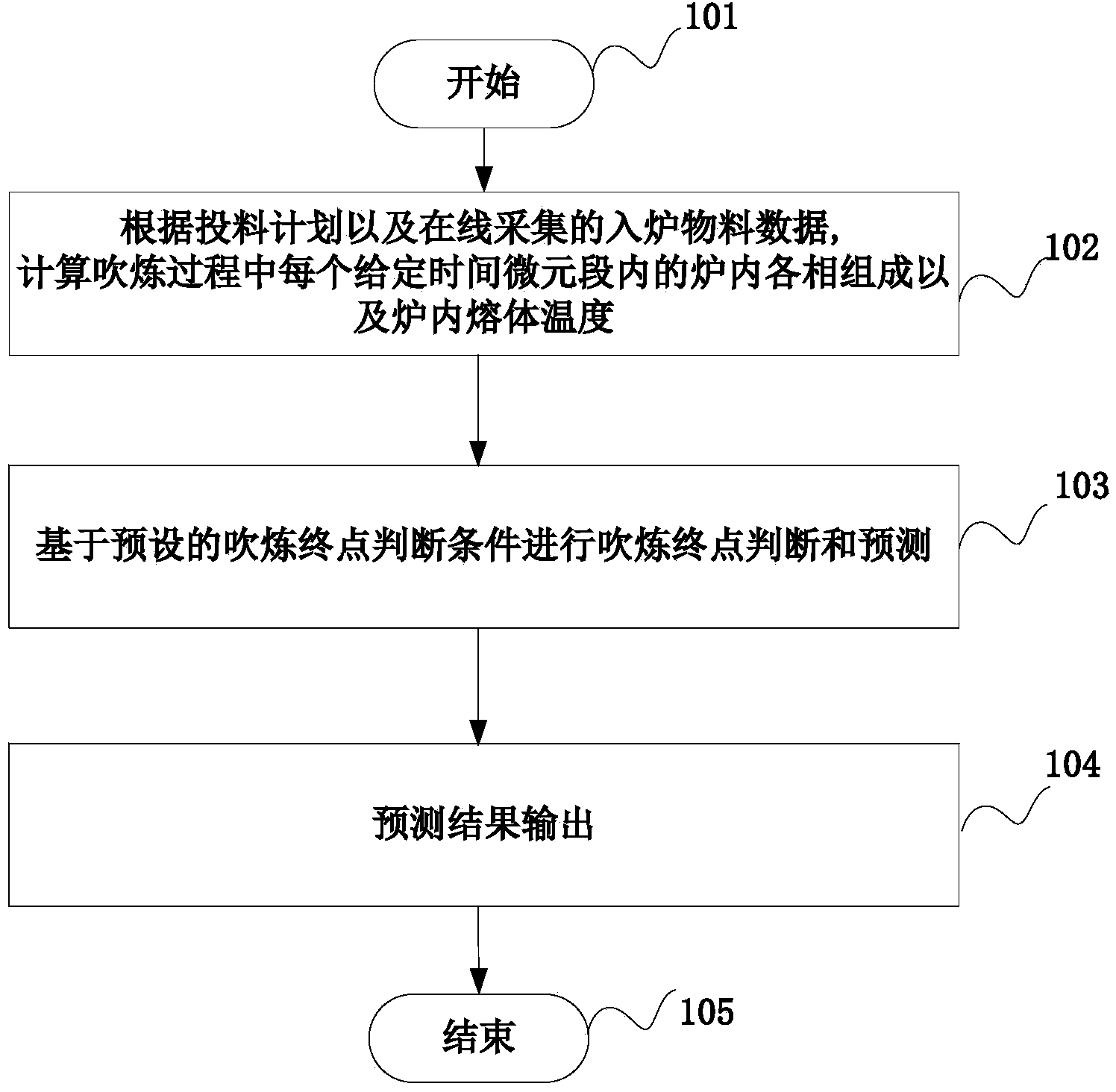

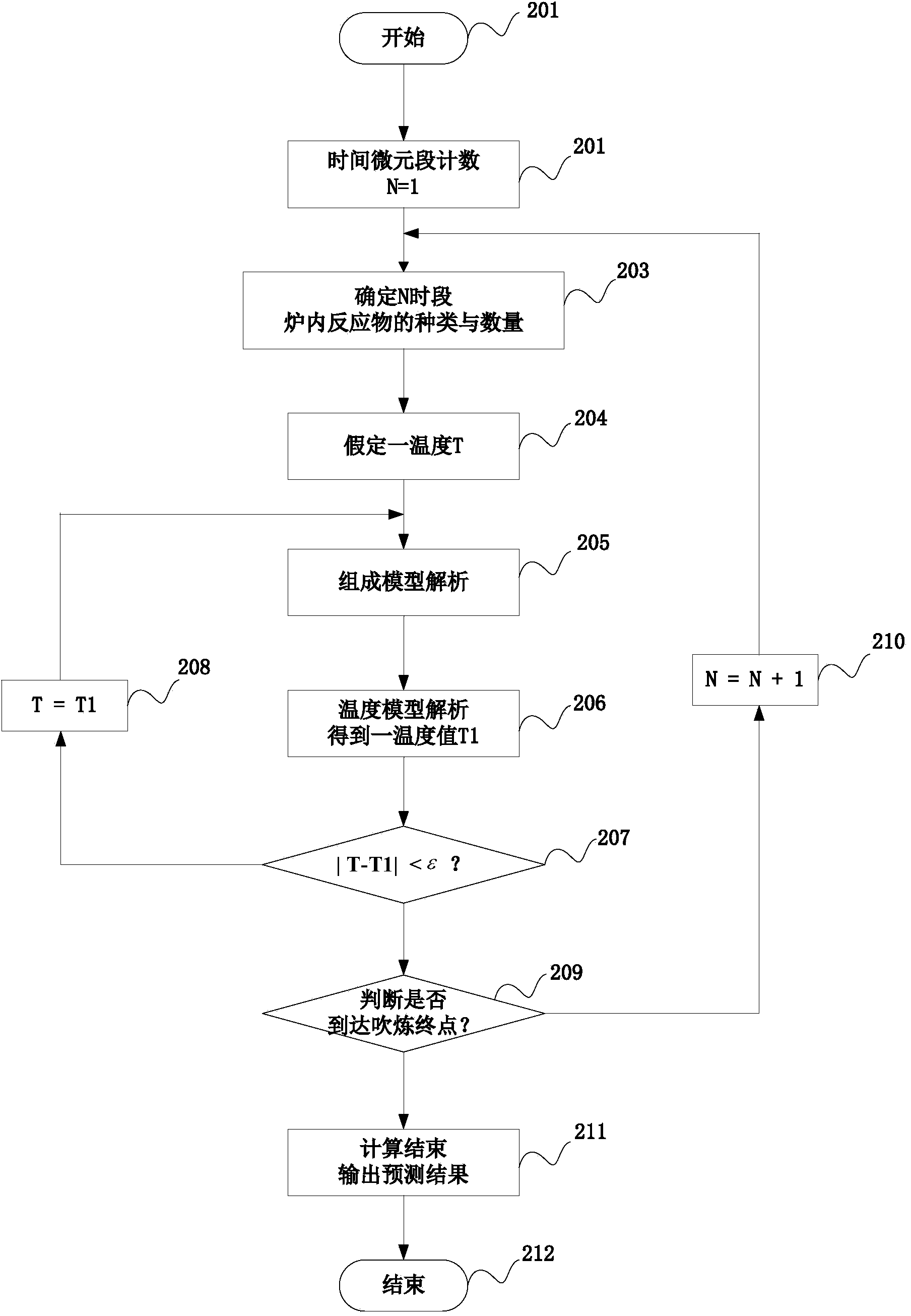

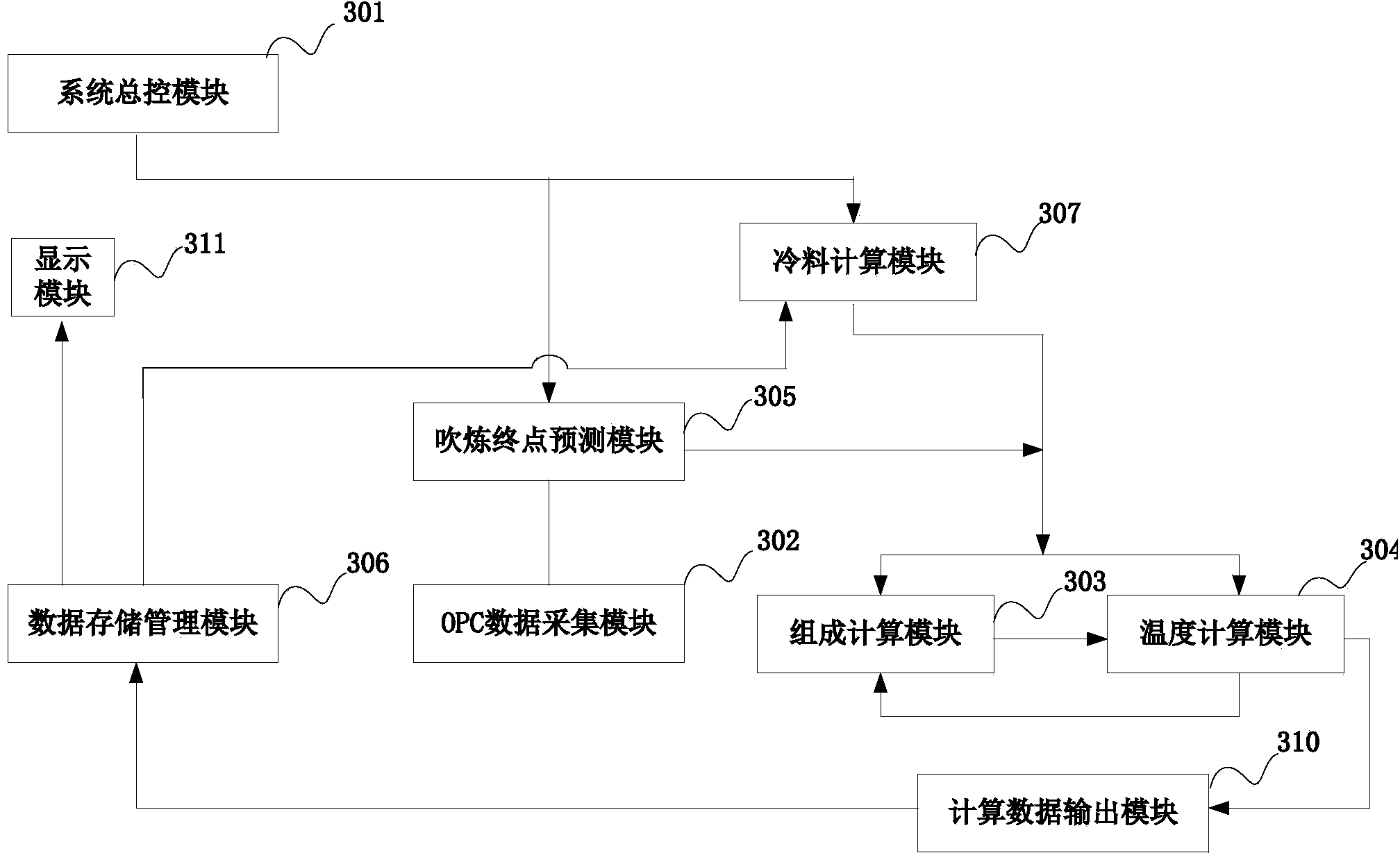

[0080] figure 1 It is a flow chart of a method for intelligent decision-making and end-point prediction of PS copper converter blowing process according to an embodiment of the present invention, and the process starts at step 101. Then, in step 102, according to the feeding plan and the furnace material data collected online, the composition of each phase in the furnace and the temperature of the furnace melt in the micro-segment of each given time during the blowing process are continuously calculated in real time. Next in step 103, based on the composition of each phase in the furnace and the temperature of the melt in the furnace in each given time micro-element period obtained in step 102, the blowing end point is determined according to the different end point judgment conditions of the slagg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com