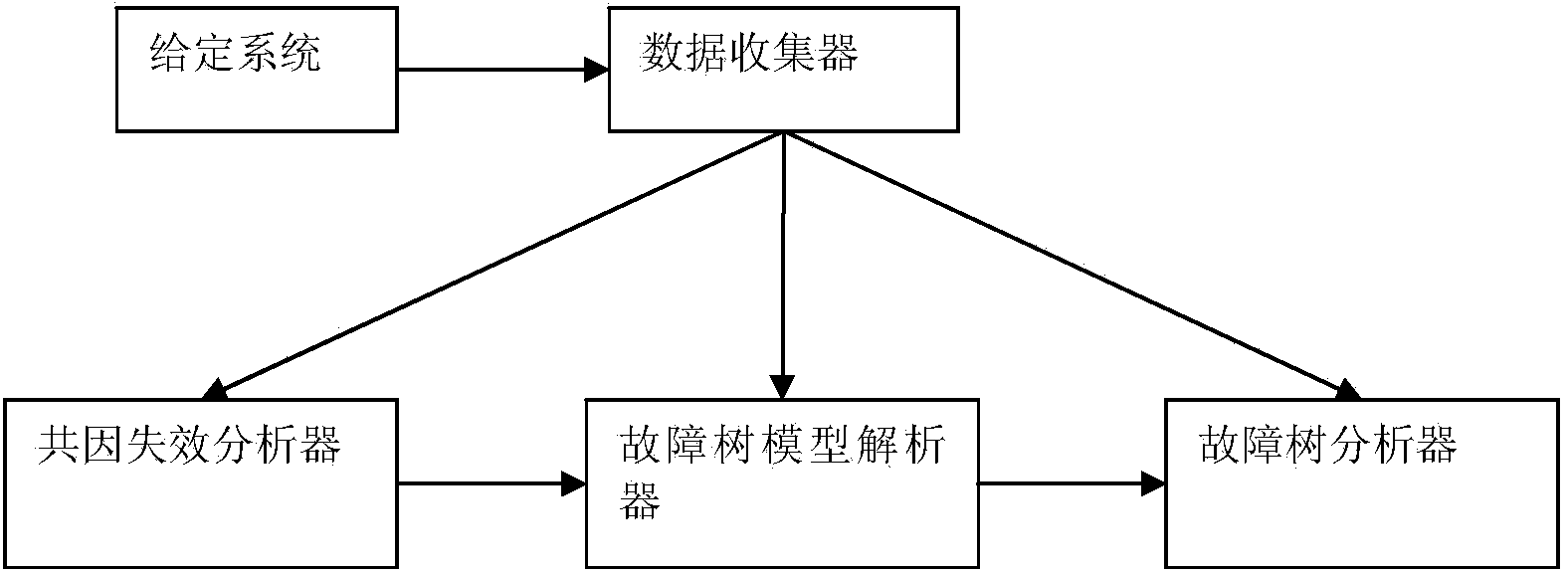

Common-cause failure reliability judging system and method based on data drive

A data-driven and reliable technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., to achieve accurate analysis and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

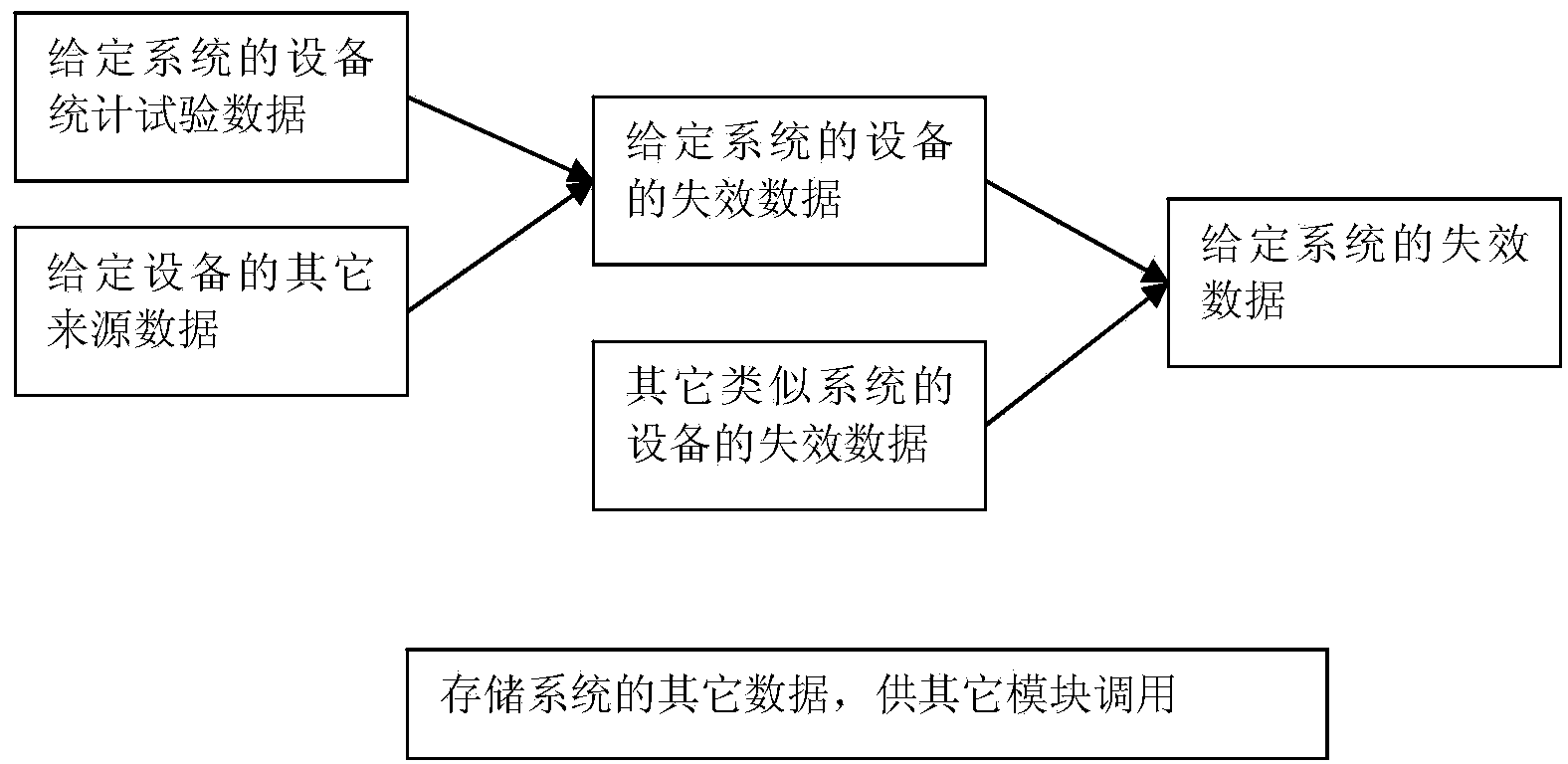

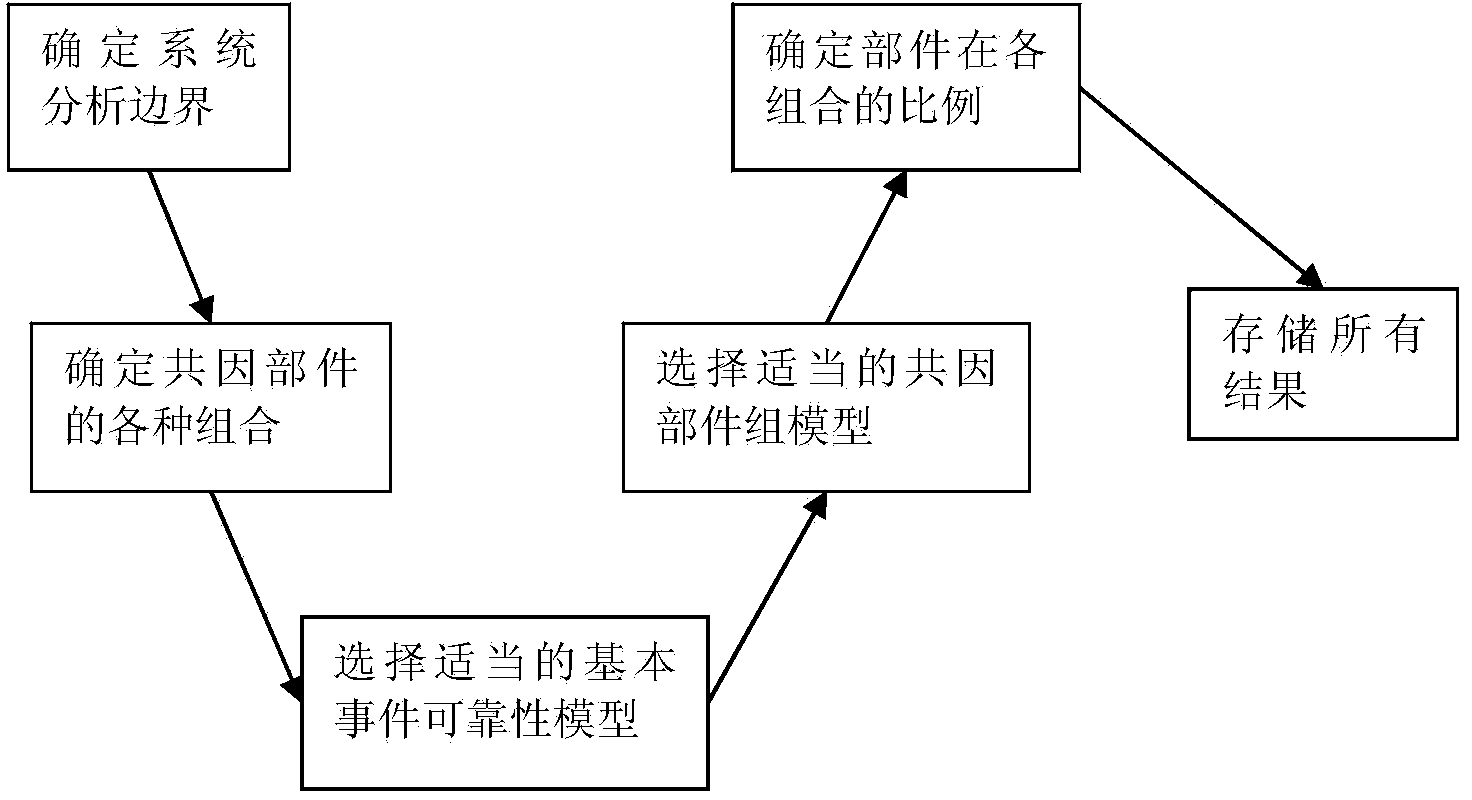

Method used

Image

Examples

Embodiment 1

[0046] to be right Image 6 The "common cause structure decomposition method" of the present invention is used for analysis.

[0047] The common cause failure analyzer obtains the common cause failure component combination according to the common cause failure data of the actual system of the nuclear power plant, for example: the system should have 4 common cause groups: [1I, 2I], [1G, 2G], [1H , 2H], [1I, 1G, 1H]. then build Figure 7-2 fault tree model. Then use the fault tree analyzer to analyze it, and get the reliability analysis result of the given system; this result can reflect the common cause failure characteristics of the given system.

[0048] Figure 7-2 In , the circle represents the basic event, the character "1I (2I)" in the circle represents the common cause failure event that "1I" and "2I" occur simultaneously, and the meanings of other characters are similar.

[0049] For comparison, Figure 7-1 According to the traditional reliability analysis method,...

Embodiment 2

[0051] to be right Figure 8 The "common cause structure decomposition method" of the present invention is used for analysis.

[0052] The common cause failure analyzer obtains the common cause failure component combination based on the common cause failure data of the actual system of the nuclear power plant, for example: the system should have 2 common cause groups: [B1, B2, B3], [B3, B4]. then build Figure 9-2 fault tree model. Then use the fault tree analyzer to analyze it, and get the reliability analysis result of the given system; this result can reflect the common cause failure characteristics of the given system.

[0053] Figure 9-2 In , the circle represents the basic event, and the character "B123" in the circle represents the common cause failure event of "B1", "B2" and "B3" occurring simultaneously, and the meanings of other characters are similar.

[0054] For comparison, Figure 9-1 According to the traditional reliability analysis method, when the common...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com