Support structure of compact high pressure sodium lamp

A high-pressure sodium lamp and support structure technology, which is applied in the field of main parts to avoid hard connection, ensure reliability, and avoid uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

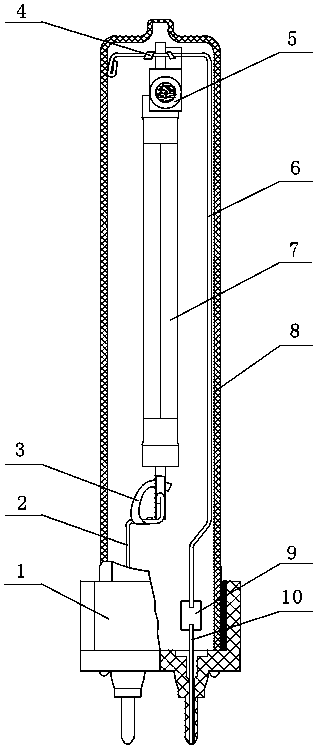

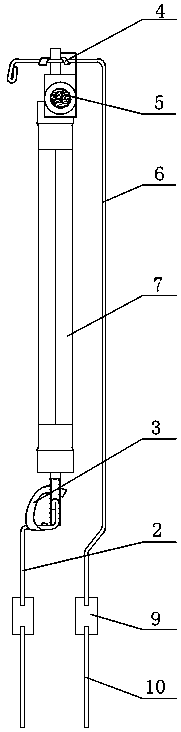

[0014] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] There are symmetrical niobium tubes 71 at both ends of the arc tube 7 .

[0016] The width of the upper end of the main bracket 6 is closely matched with the inner diameter of the bulb 8, which mainly plays a role in supporting and positioning, so that the main bracket will not shake in the bulb, and there is a downward bending shape 61 on one side of the upper end, in order to prevent the cutting of the molybdenum rod end The burr scratches the quartz glass, and there is a circular arc concave 62 in the middle of the upper end, and its diameter is consistent with the niobium tube 71 to match.

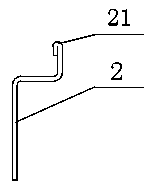

[0017] The sub-support 2 is bent at right angles to molybdenum wires smaller than 1 / 2 of the inner diameter of the niobium tube 71. Molybdenum rods with too large diameters cannot be used, because one end needs to be pressed in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com