Flow frame assembly and flow battery

A technology of flow battery and flow frame, applied in fuel cells, regenerative fuel cells, fuel cell grouping, etc., can solve the problems of low energy efficiency and large bypass current loss, so as to improve current efficiency and reduce bypass current. , the effect of increasing the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

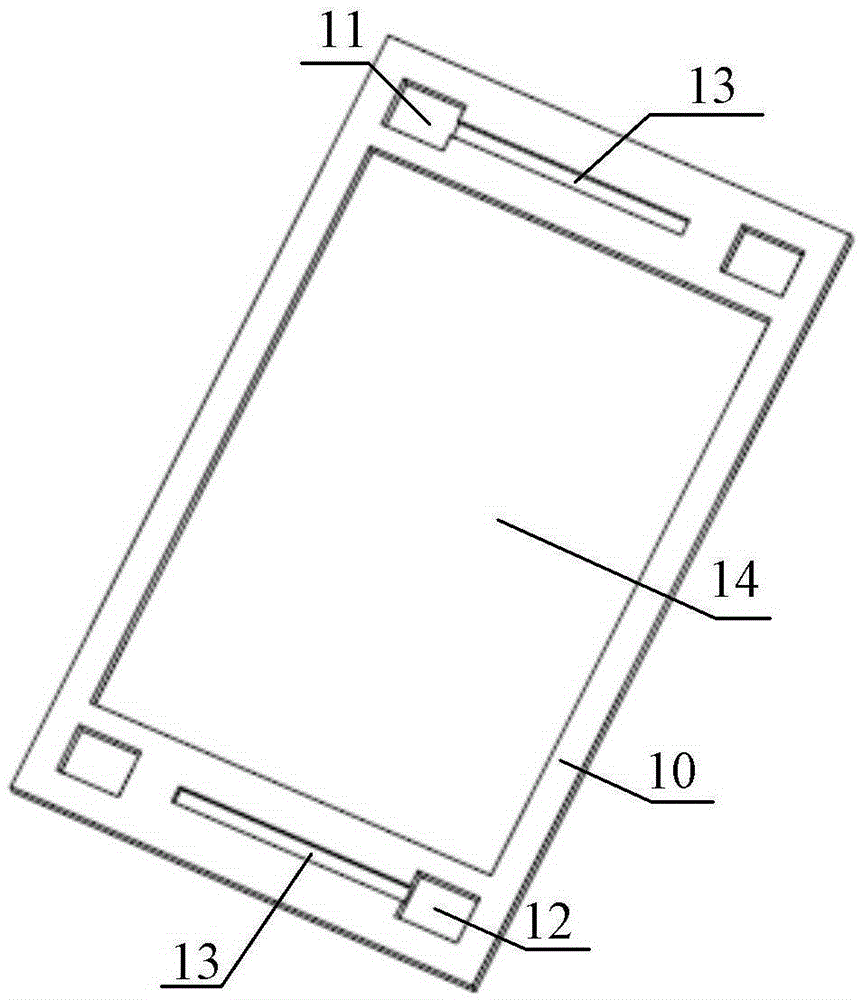

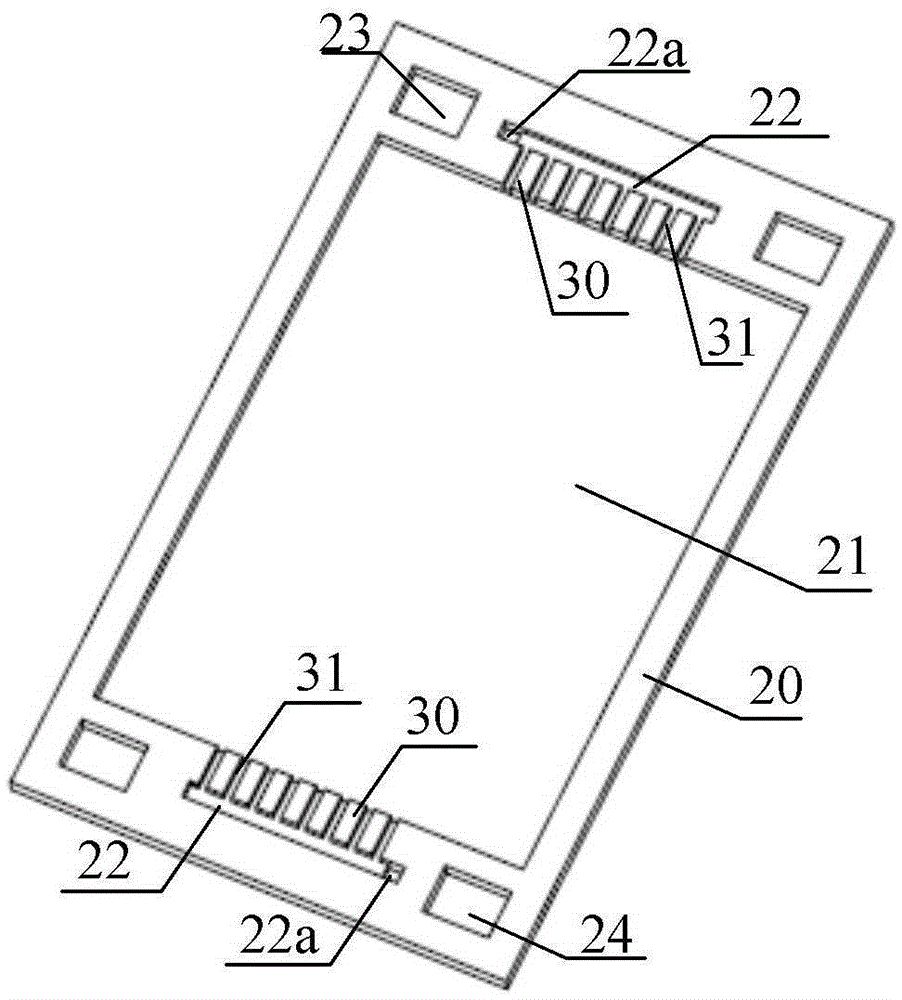

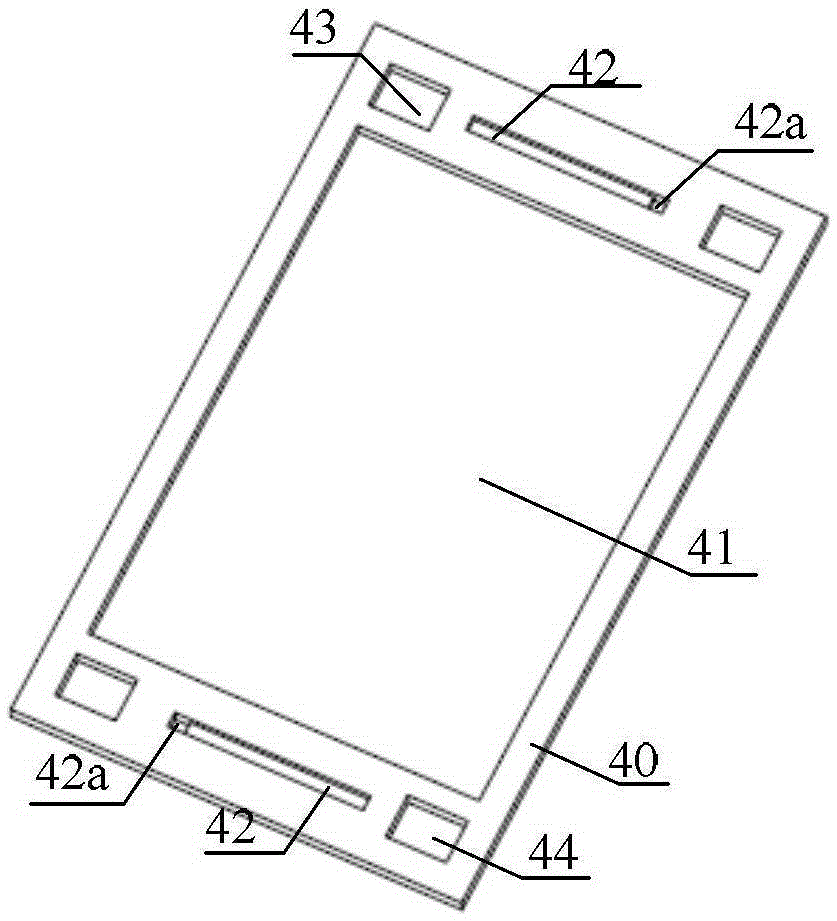

[0027] As a first aspect of the present invention, a liquid flow frame assembly is provided. like Figure 1 to Figure 4 As shown, the liquid flow frame assembly includes a plurality of stacked bodies, each of which has a flow channel section, and the flow channel sections of the multiple bodies are sequentially connected end to end to form a flow channel. Since the flow channel sections on the stacked bodies are connected end to end in order to form a flow channel, after the electrolyte flows into the liquid flow frame assembly from the main pipe, it needs to flow through multiple flow channel sections in sequence before reacting with the electrodes, thereby The liquid flow path of the electrolyte is increased, thereby reducing the bypass current a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com