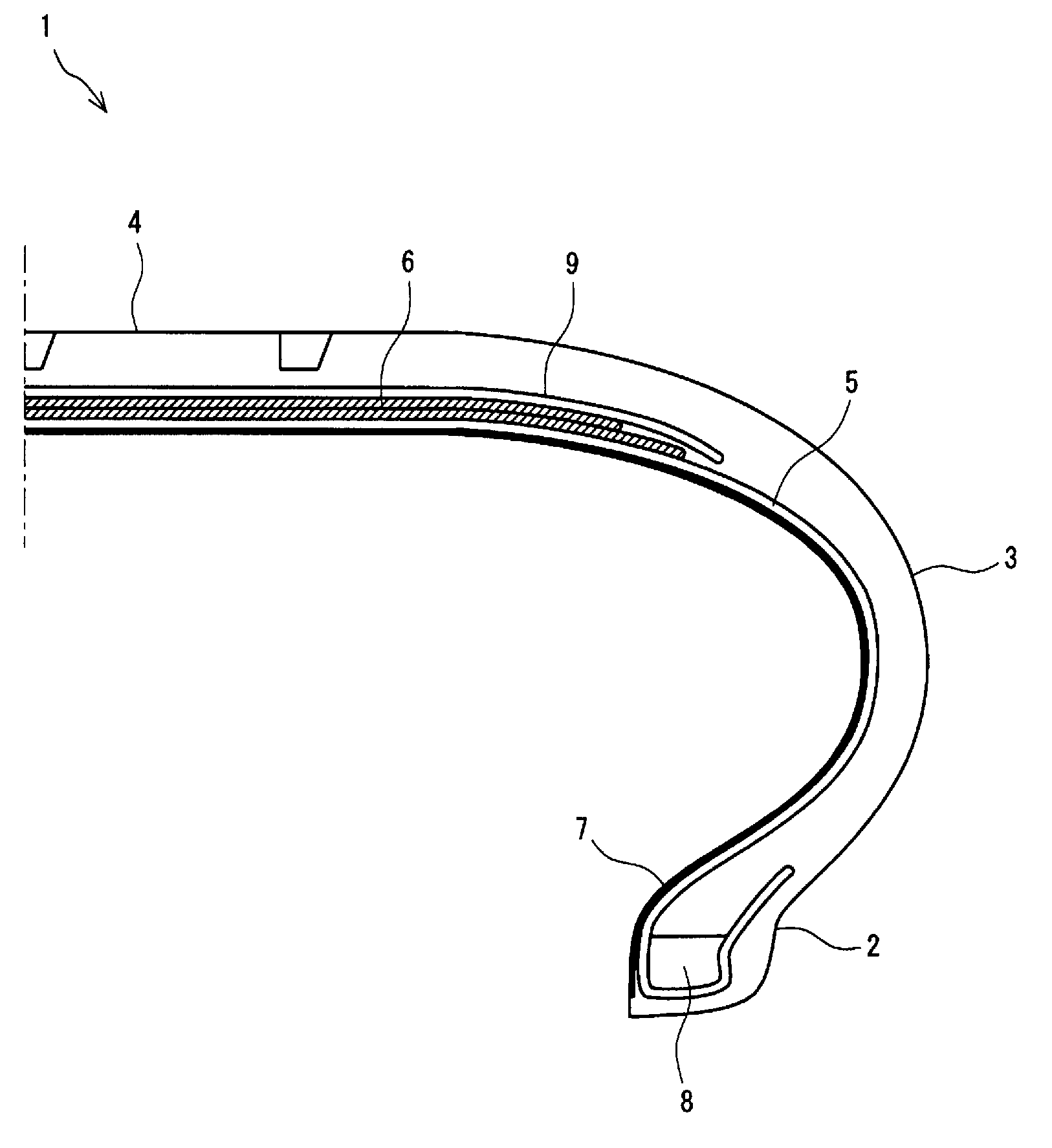

Inner liner for pneumatic tires, method for producing same, and pneumatic tire

A technology for pneumatic tires and inner liners, which is applied in the direction of pneumatic tires, special tires, tire parts, etc., can solve problems such as fracture and cracking, achieve easy and reliable manufacturing, maintain gas barrier properties, and suppress the increase in manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0317] The inner liner of the present invention is not limited to the above-mentioned embodiments. For example, other layers may be included in addition to the A layer and the B layer. The type of the resin composition constituting the other layer is not particularly limited, but a resin composition having high adhesiveness to the A layer and / or the B layer is preferable. As another layer, a layer having a molecular chain having the same hydroxyl group or the like as the gas barrier resin in the A layer or a functional group in the B layer (for example, a carbamate group or a urethane group in the molecular chain of TPU) is particularly preferable. isocyanate group) reacts to form a bonded functional group.

[0318] In addition, in the inner liner of the present invention, support layers may be laminated on both surfaces or one surface of the above-mentioned laminated body of eight or more resin layers. The support layer is not particularly limited, and may not be a resi...

manufacture example 1

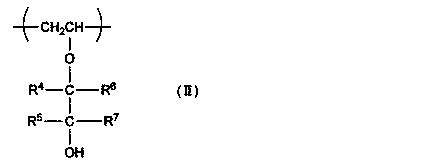

[0321] (Manufacture example 1 [manufacture of EVOH1])

[0322] 20,000 parts by mass of vinyl acetate, 1,020 parts by mass of methanol, and 2,2'-azobis(4-methoxy-2,4-dimethyl valeronitrile) 3.5 parts by mass, after nitrogen substitution was carried out while stirring, ethylene was introduced and adjusted to an internal temperature of 60°C and an ethylene pressure of 59Kg / cm 2 , keep the temperature and pressure for 4 hours, stir to make it polymerized. Next, 10 mass parts of sorbic acid (SA) (0.05 mass % with respect to the input vinyl acetate) was dissolved in methanol, and it added as a 1.5 mass % solution. The polymerization rate was 30% with respect to the vinyl acetate charged. The copolymerization reaction solution was taken out and supplied, and methanol vapor was introduced from the bottom of the column to remove unreacted vinyl acetate from the top of the column to obtain a 40% by mass methanol solution of the copolymer. In this copolymer, the ethylene unit con...

manufacture example 2

[0324] (Manufacturing example 2 [manufacture of EVOH2])

[0325] 20,000 parts by mass of vinyl acetate, 1,020 parts by mass of methanol, and 2,2'-azobis(4-methoxy-2,4-dimethyl valeronitrile) 3.5 parts by mass, after nitrogen substitution was carried out while stirring, ethylene was introduced and adjusted to an internal temperature of 60°C and an ethylene pressure of 59Kg / cm 2 , keep the temperature and pressure for 4 hours, stir to make it polymerized. Next, 10 mass parts of sorbic acid (SA) (0.05 mass % with respect to the input vinyl acetate) was dissolved in methanol, and it added as a 1.5 mass % solution. The polymerization rate was 30% with respect to the vinyl acetate charged. The copolymerization reaction solution was taken out and supplied, and methanol vapor was introduced from the bottom of the column to remove unreacted vinyl acetate from the top of the column to obtain a 40% by mass methanol solution of the copolymer. In this copolymer, the ethylene unit co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com