Coating film

A technology of coating film and coating layer, which is applied in the field of coating film, can solve problems such as increased liquid replacement operations, poor adhesion of surface functional layers, and insufficient stability of coating liquid, etc., and achieves excellent sliding properties and tight adhesion Excellent performance and high industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

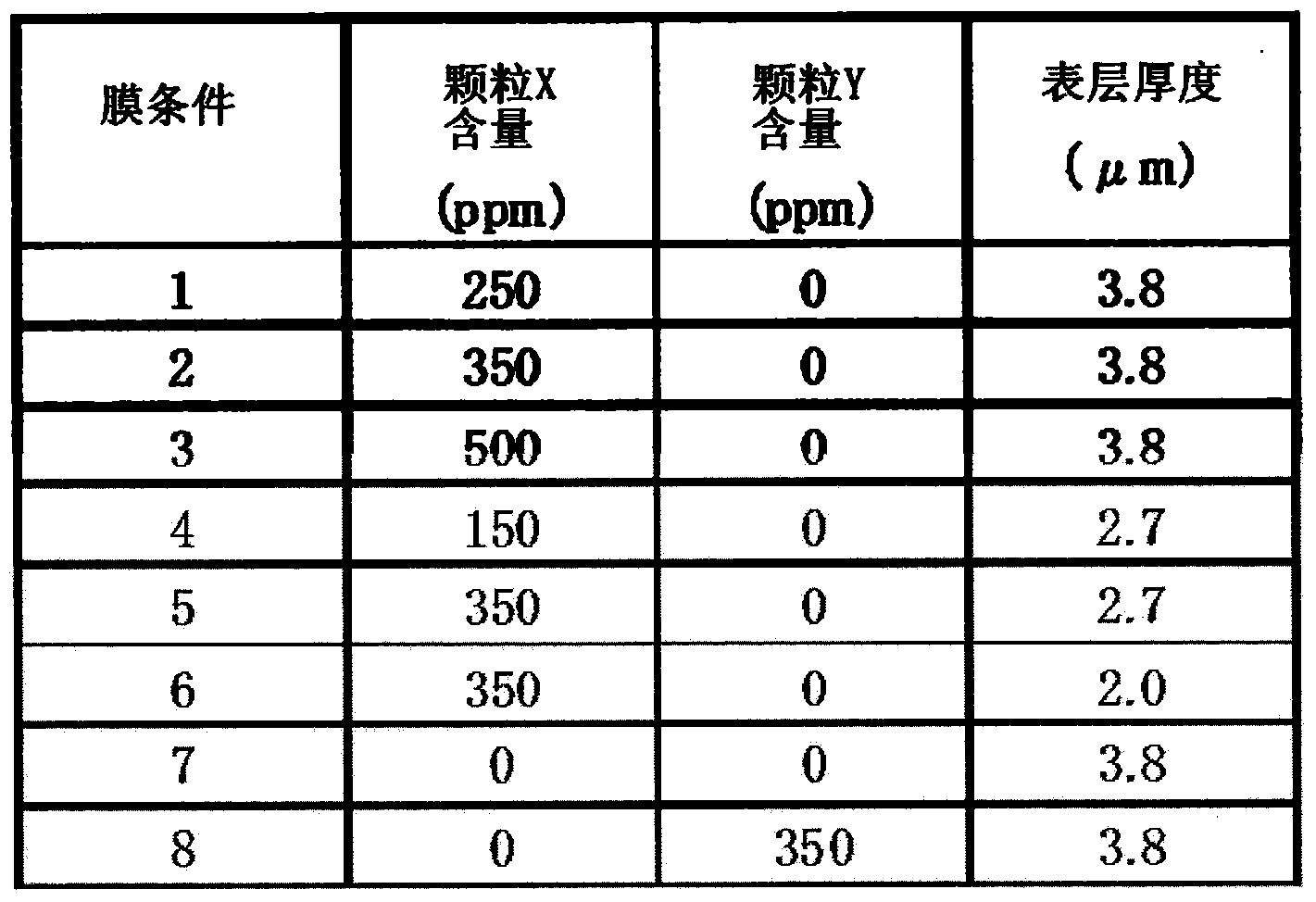

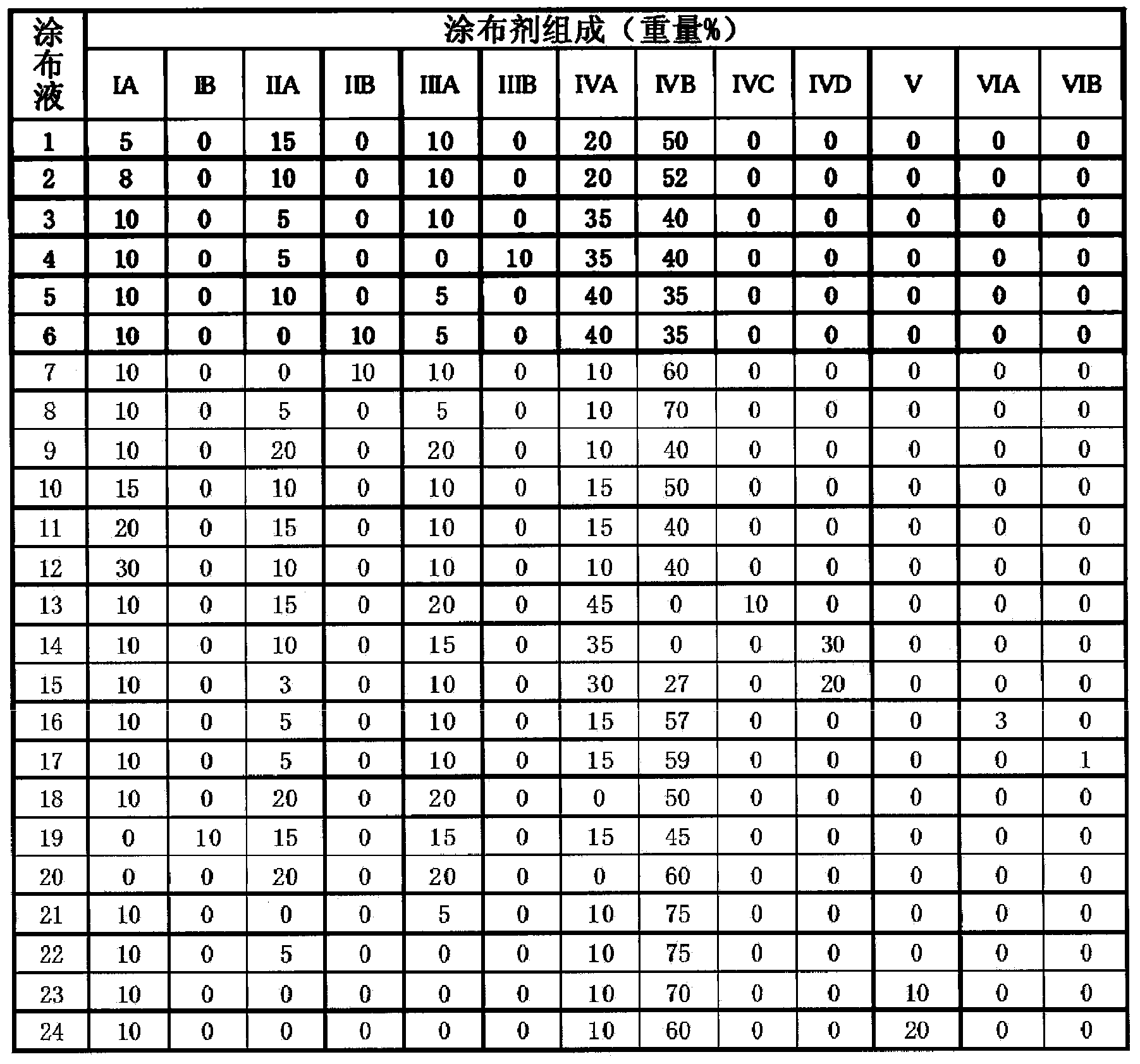

[0144] The mixed raw material (particle content 250ppm) obtained by mixing polyester (A), (B) and (C) at a ratio of 90%, 5%, and 5% respectively is used as the raw material for the outermost layer (surface layer), and the The mixed raw materials obtained by mixing polyesters (A) and (B) at a ratio of 95% and 5% are used as raw materials for the intermediate layer, and are supplied to two extruders respectively, and after melting at 285°C, set at 40 On a cooling roll at ℃, co-extrude two types of three layers (surface layer / intermediate layer / surface layer = 1:31:1 discharge rate, surface layer thickness 3.8 μm design) and allow it to cool and solidify to obtain undrawn Stretch the sheet (film condition 1 of Table 1). Next, after stretching 3.4 times in the longitudinal direction at a film temperature of 85° C. by using the difference in roll speed, the coating liquid 3 shown in Table 2 below was applied to both sides of the longitudinally stretched film, introduced into a tent...

Embodiment 2~26

[0146] In Example 1, the amount of particles contained in the polyester film and the thickness of the surface layer were changed to the film conditions shown in Table 1, and the composition of the coating agent was changed to the composition of the coating agent shown in Table 2. It produced similarly to Example 1, and obtained the polyester film. As shown in Table 3, the obtained coating film had good slipperiness and transparency, and good interference spots and adhesion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com