Surface property inspection device and surface property inspection method

一种表面特性、检查装置的技术,应用在测量装置、采用电装置、电磁测量装置等方向,能够解决产品不能再使用、无法产品检查等问题,达到通用性高、广泛阻抗变化、简单电路结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

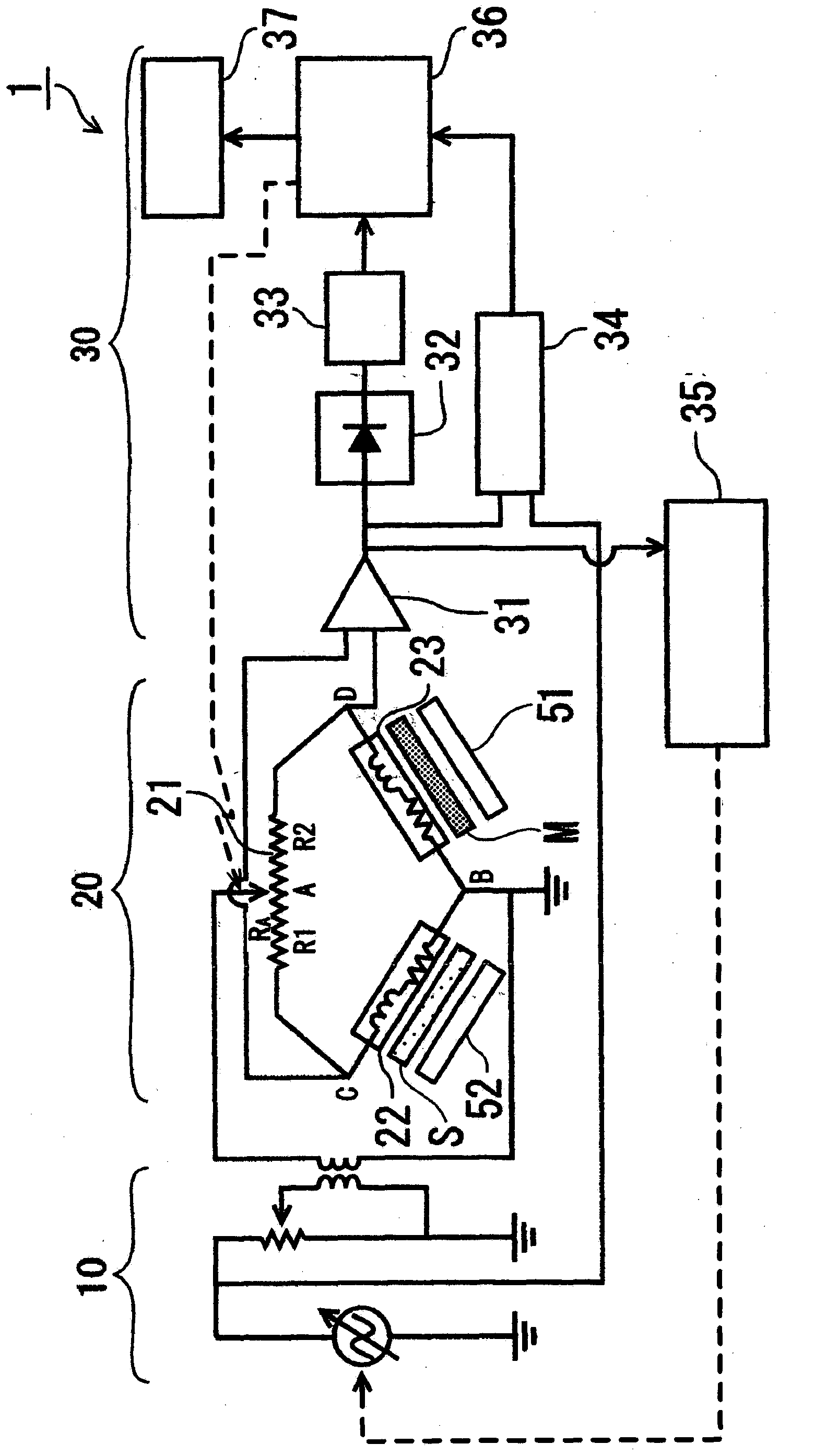

[0049] Such as figure 1 As shown, the surface characteristic inspection device 1 according to the embodiment of the present invention includes an AC power source 10 , an AC bridge circuit 20 , and a determination device 30 .

[0050] The AC power supply 10 is configured to be able to supply AC power with a variable frequency to the AC bridge circuit 20 .

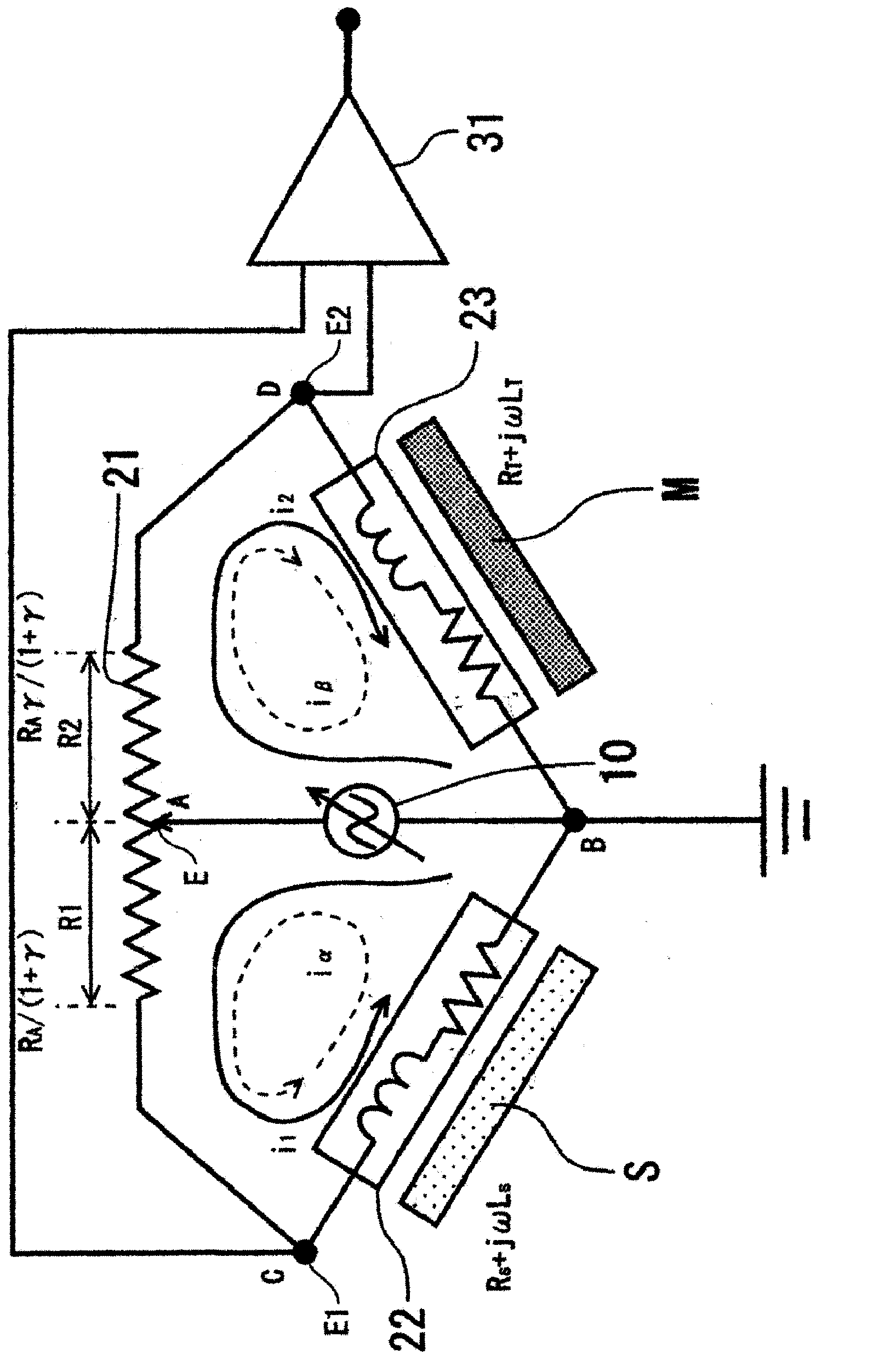

[0051] The AC bridge circuit 20 includes a variable resistor 21, a reference detector 22 provided with a magnetic sensor for detecting the magnetic properties of the reference sample S, and an inspection detector 23 provided with a sensor for detecting the magnetic properties of the object M to be inspected. A magnetic sensor with magnetic properties.

[0052] The variable resistor 21 is configured to be able to distribute the resistance RA into the resistance R1 and the resistance R2 so that the distribution ratio γ is variable. Resistor R1, resistor R2 together with reference detector 22 and check detector 23 constitute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com