System with battery charging device and vehicle electrical system power supply stage

A technology for battery charging and vehicle power supply, applied in the field of voltage source systems, can solve problems such as expensive and non-optimal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

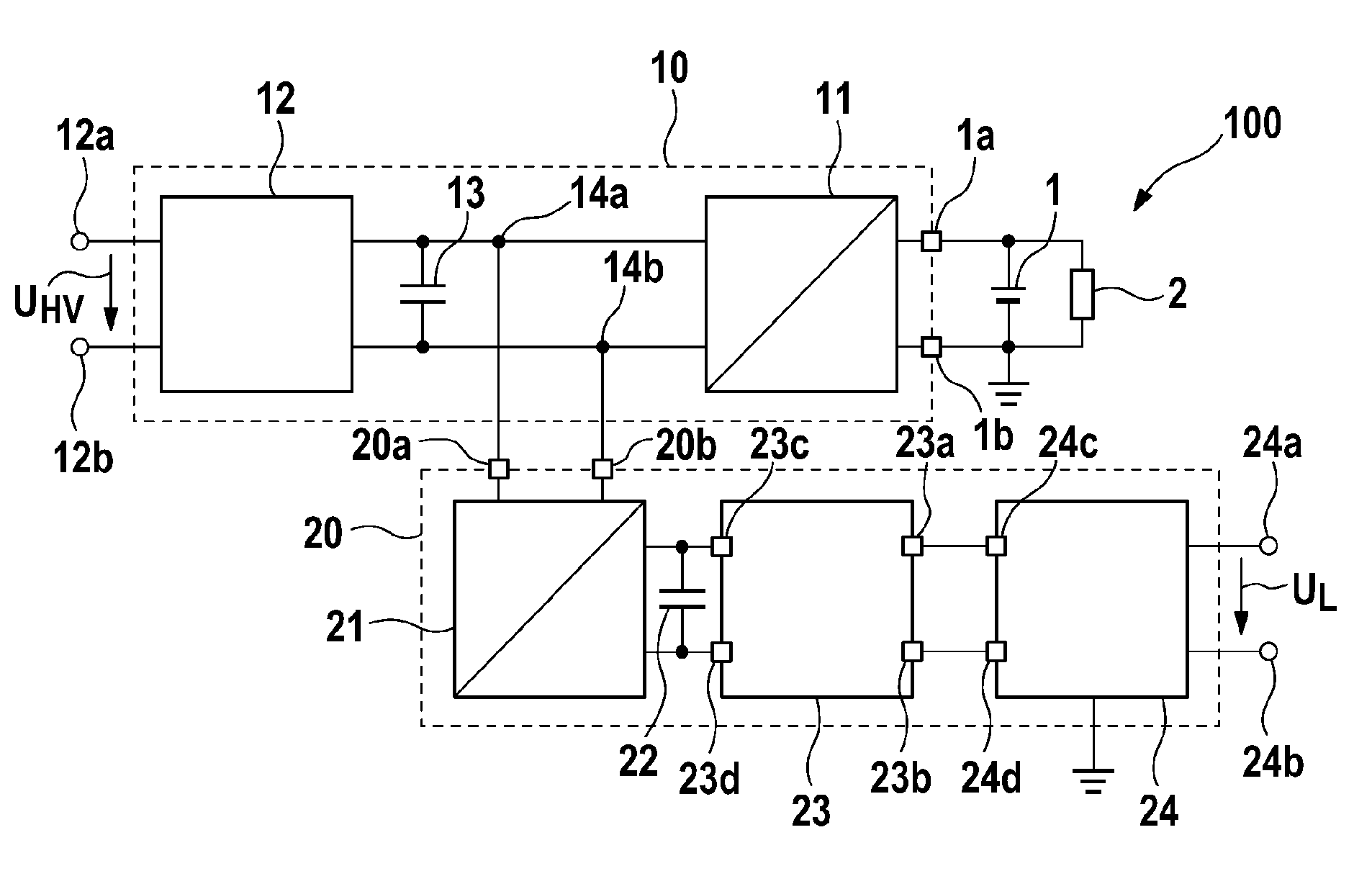

[0026] figure 1 A schematic diagram of a system 100 with a battery charging device 20 and an on-board power supply stage 10 that can supply, for example, a 12V on-board power supply is shown. The on-board power supply stage 10 can have an on-board power DC-voltage converter 11 , a DC-voltage intermediate circuit 13 and a step-up / step-down converter 12 . An input voltage U can be applied at the input terminals 12a, 12b of the vehicle power supply stage 10 HV , for example from the input voltage of the intermediate circuit of a high-voltage power source, eg a traction battery of an electrically operated vehicle, such as a hybrid vehicle or an electric vehicle. Input voltage U HV For example, it can be between 50 V and 500 V and can be boosted by the step-up / down converter 12 . Here, the boost / buck converter 12 can convert the input voltage U HV For example boost 25V.

[0027] exist figure 2 In , an exemplary configuration of the boost / buck converter 12 is shown schematica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com