Mulberry leaf picking device of automatic worm and gear type driving mulberry leaf picking machine

A technology of automatic picking and worm gear, which is applied in the direction of picking machines, harvesters, agricultural machinery and tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

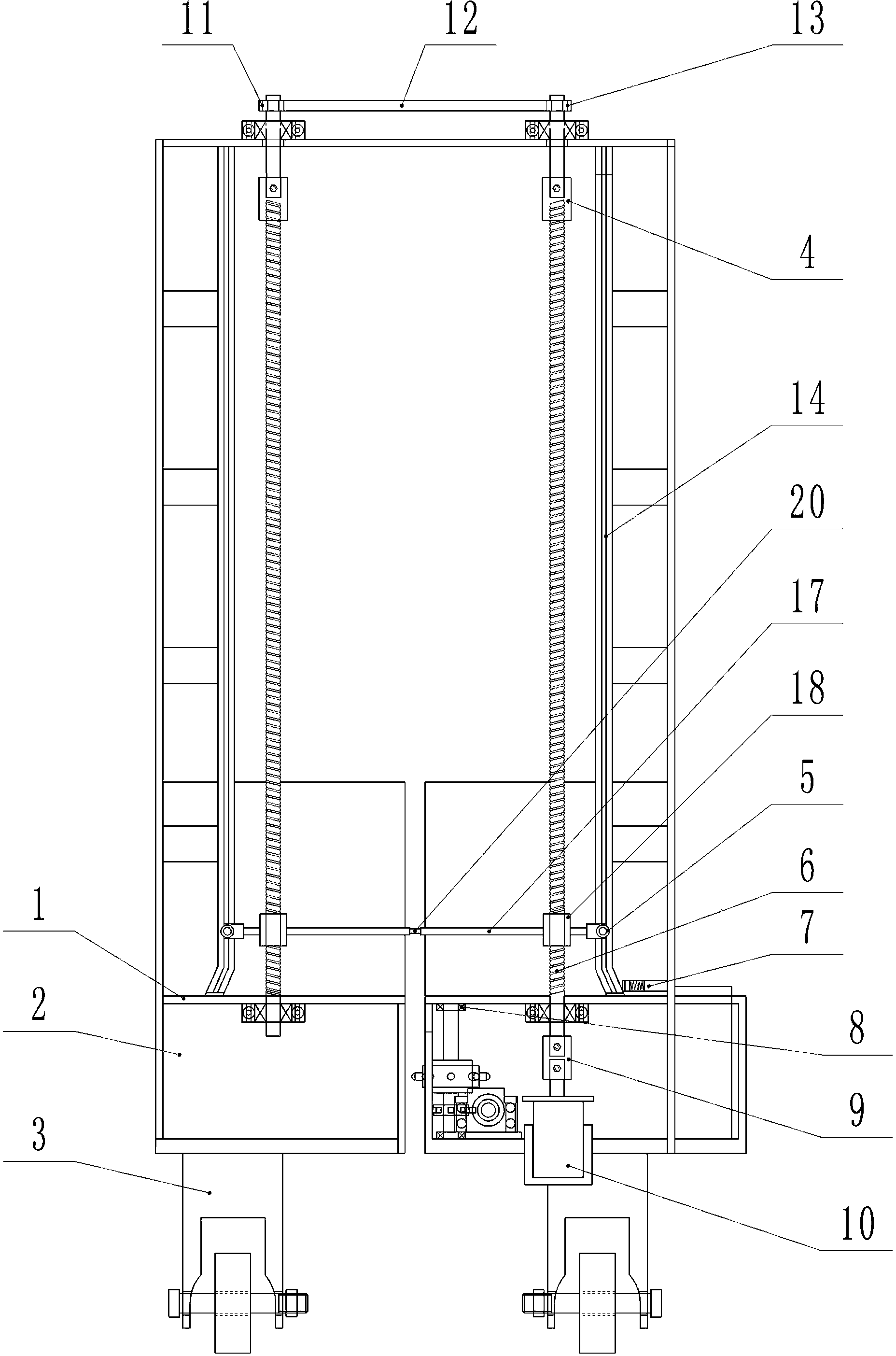

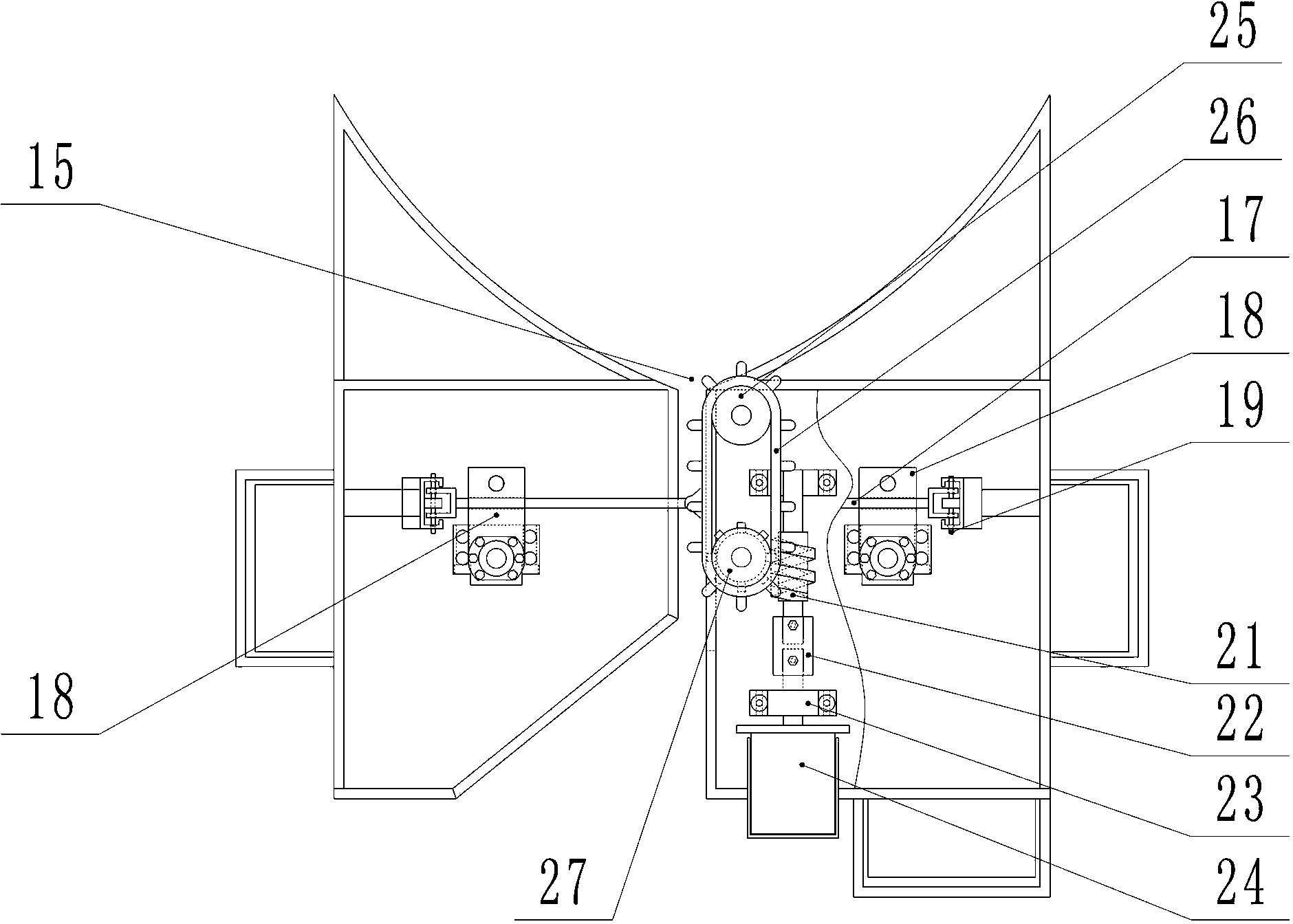

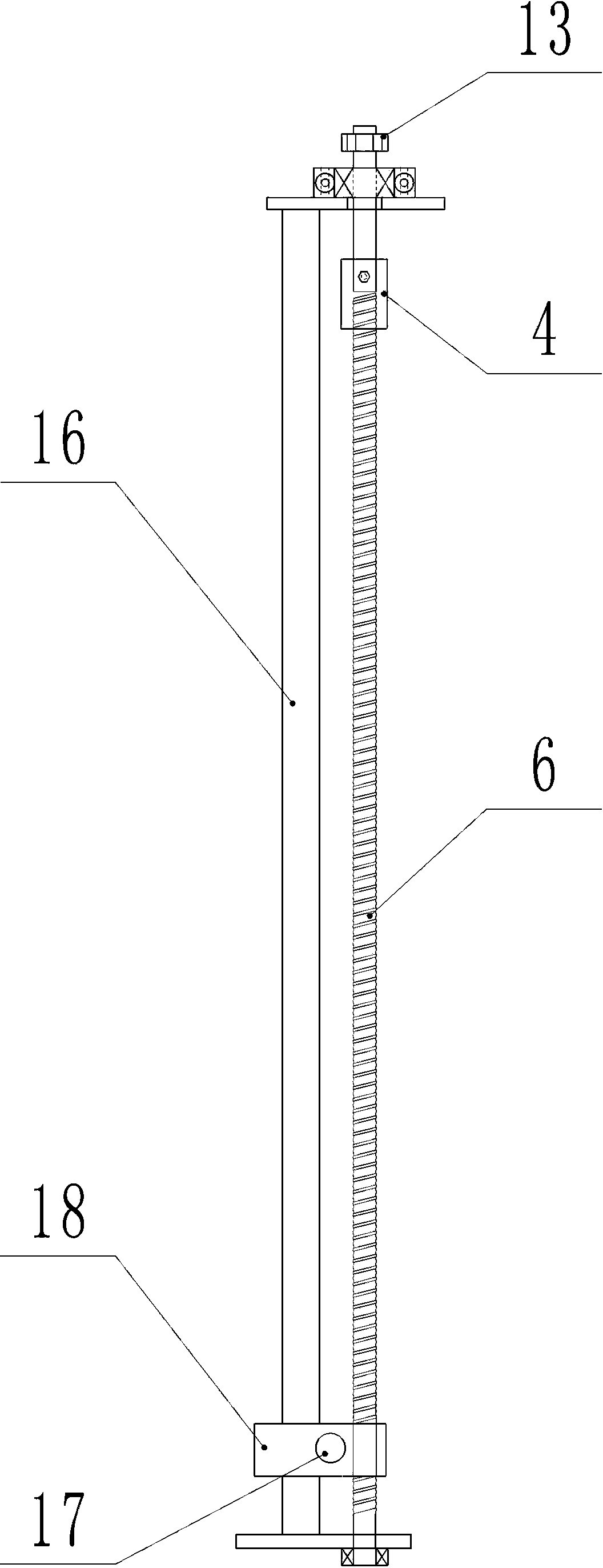

[0022] refer to Figure 1-Figure 4 , a mulberry leaf picking device driven by a worm gear type automatic mulberry leaf picking machine, including an inverted Y-shaped guide rail 14, a screw mandrel 6, a mulberry picking rod 17, a fixed block 18 and a cutter 20 arranged symmetrically on the left and right, and the cutter 20 is arranged At the front end of the mulberry picking bar 17, the left and right two cutters are corresponding, the inverted Y-shaped guide rail 14 is provided with a guide wheel 5, the guide wheel 5 is connected with the mulberry picking bar 17 by a pin shaft 19, and the rear end of the mulberry picking bar 17 Matching by guide wheel 5 and inverted Y-shaped guide rail 14, the rear portion of picking mulberry bar 17 is covered with fixed block 18, and one end of fixed block 18 is enclosed within on the support bar 16, and the other end has threaded through hole and screw mandrel 6 to match, The screw rod 6 is connected with the reduction motor 10, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com